Paint and Bake Cabin with Ceiling Opened for Handling by Overhead Crane

Hangzhou Mig Packaging Co., Ltd.- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Downdraft

- Heating Mode:Gas Heating

Base Info

- Model NO.:IT-IND

- Paint Mist Treatment:Dry-type

- Condition:New

- Airflow:Downdraft

- Extraction Area:6m2

- Brightness:>1,400lux

- Air Volume:35,000m3,H

- Empty Loaded Air Speed:+,-0.35m,S

- Heats:315kw Heat Exchanger

- Maximum Working:80 Celsius

- Controls:CE Standard

- Inverter:Schneider

- Stack Light:Yes

- Rated Power:28kw

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:7000 X 4000 X 3000mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

Description

Basic Info.

Model NO. IT-IND Paint Mist Treatment Dry-type Condition New Airflow Downdraft Extraction Area 6m2 Brightness >1,400lux Air Volume 35,000m3/H Empty Loaded Air Speed +/-0.35m/S Heats 315kw Heat Exchanger Maximum Working 80 Celsius Controls CE Standard Inverter Schneider Stack Light Yes Rated Power 28kw Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 7000 X 4000 X 3000mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

Paint and Bake Cabin with Ceiling Opened for Handling by Overhead Crane1.FEATURES

The spray booth is designed for painting and drying heavy machinery. It comes with opening ceiling, which facilitates the conveyance of heavy duty products by overhead crane. The opening and closing of the ceiling is achieved by using pneumatic device.

The airflow is downdraft, with extraction through exhaust plenum chambers on the left/right/rear side of the booth. And there is gantry structure which reinforces the overall strength of the cabin.

Infitech designs and provides different dimensions and configurations spray booths for the automotive and industrial manufacturing industry. Feel free to send your inquiries.

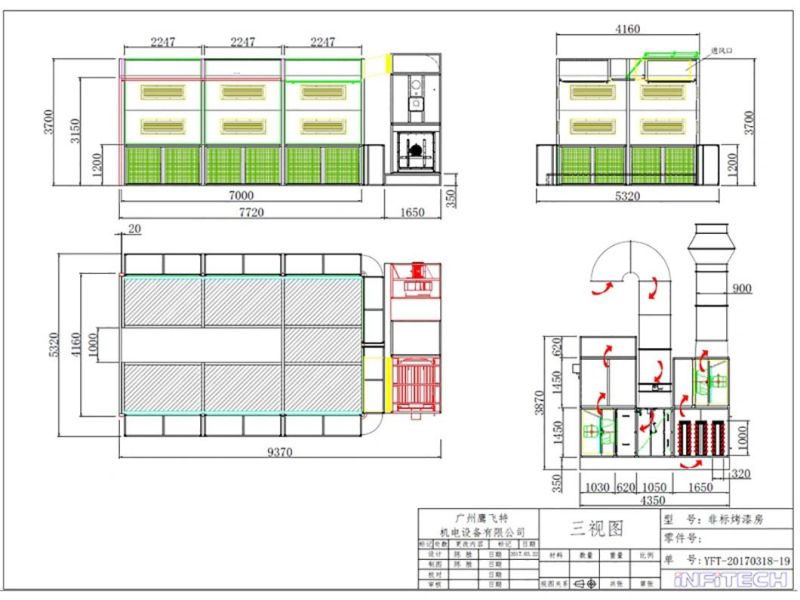

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | Customized Spray Booth for Heavy Machinery |

| Design standard | BS EN 13355: 2004 + A1: 2009 BS EN 60204: 2006 + A1: 2009 |

| Internal dimensions | 7000 X 4000 X 3000mm (L X W X H) |

| External dimensions | 9370 X 5320 X 3700mm (L X W X H) |

| Entrance door | 1 set, 3400 X 3000 mm (W X H) |

| Personnel door | 1 set, 800 X 2000 mm (W X H) |

| Sidewall lighting | 16 sets, each 4 X 18W, 1,152W total, LED lamp |

| Brightness | >1,400LUX |

| Filters | Pre-filter, ceiling filter, floor filter, exhaust filter |

| Air intake | Direct-type turbine fan, 11KW SIEMENS motor |

| Air exhaust | Direct-type turbine fan, 11KW SIEMENS motor |

| Air volume | 35,000m3/h |

| Empty loaded air speed | +/-0.35m/s |

| Maximum working temperature | 80ºC |

| Heats | 315KW heat exchanger, RS5D gas burner |

| Controls | CE standard control box |

| Rated power | 28KW |

Design

3.DETAILS

| Airflow • Downdraft airflow for spray and cure • Controlled airflow ceiling | Construction • White pre-coated galvanized steel • Dual-skin insulated panels filled with rock wool, 60mm thick • 600mm high plenum • With exhaust plenum chambers on the left/right/back side • Special item: With overhead opening, which facilitates the conveying of heavy work-piece into the booth by overhead crane |

| Doors • 2-wing big entry door • Personnel door with observation window (in the entry door) | Heat • Intake and exhaust motors, 11kw, SIEMENS motor • Gas heating |

| Filtration • Pre-filter: G3 grade pre-filter bag filter • Ceiling filter: F5 grade filter cotton, Model SP-600G • Floor filter: Pleated andreae filters + G2 grade fiberglass paint arrestor filters • Exhaust filter: Simple activated carbon filter mat, M type | Controls • PLC controller, pressure gauge Functions: Painting, heating painting, flash, baking, cooling, lighting, emergency stop switch, failure indication, over-temperature alarm indication, fan and heating system interlock |

FAQQ: Instead of using overhead crane, I need floor conveyor. Can you integrate the conveying system with your spray booth?A: Certainly. We can customize our solution according to your production systems. Infitech large equipment paint spray booths can effectively support you.

Q: Can you supply open face spray booth for industrial manufacturing?A: Yes. Please send your inquiries, we will analyze your request carefully, and get back to you with our solution.

Q: I need direct-fired gas heating system for the spray booth.A: No problem. Our spray booth is available with direct gas fired heating system.

Q: What about the payment terms?A: Usually, we accept 50% down payment, and balance settled before EXW.

Q: What is the delivery schedule?A: For non-standard spray booths, we need to check the schedule case by case depending on the specific project itself. But usually, it takes about 45 days for production.

For standard spray booth, the production lead time is 20 days.

The shipping schedule is usually 30-45 days depending on the destination port.

Q: What about warranty?A: We offer 2-year warranty for main components.