Single Stage Automation Paddy Parboiled Rice Mill Milling Production Plant

Nanjing Zhanyi Technology Co., Ltd.- Warranty:12 Months

- Type:Rice Mill

- Application:Rice flour, Wheat, Rice,Corn,Millet, Sorghum, Buckwheat.Others

- Voltage:380V

- Appearance:Vertical

- Press Materials:Rice

Base Info

- Model NO.:parboiled rice mill

- Press Series:Fourth

- Condition:New

- Customized:Customized

- Capacity:1 Ton Per Hour

- Size:According to Capacity

- Factory Visiting:Yes

- Machine Test:Supported

- Raw Material:Paddy and Rice

- Final Product:Parboiling Rice

- Transport Package:Seaworthy Wood Case

- Specification:CE, ISO, SGS, CCC

- Trademark:LY

- Origin:Jiaozuo of Henan Province

- HS Code:8437800000

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. parboiled rice mill Press Series Fourth Condition New Customized Customized Capacity 1 Ton Per Hour Size According to Capacity Factory Visiting Yes Machine Test Supported Raw Material Paddy and Rice Final Product Parboiling Rice Transport Package Seaworthy Wood Case Specification CE, ISO, SGS, CCC Trademark LY Origin Jiaozuo of Henan Province HS Code 8437800000 Production Capacity 100 Sets/YearProduct Description

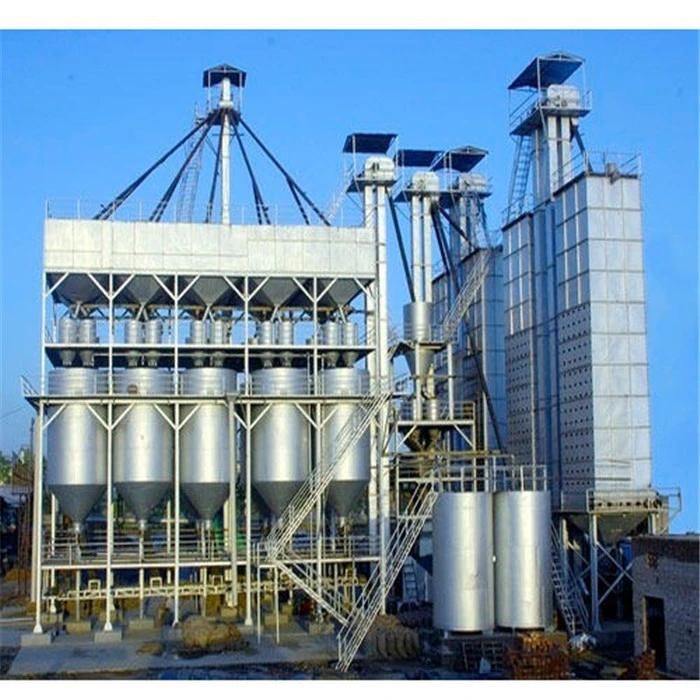

Single Stage Automation Paddy Parboiled Rice Mill Milling Production PlantSingle Stage Automation Paddy Parboiled Rice Mill Milling Production Plantdescription:

Single Stage Automation Paddy Parboiled Rice Mill Milling Production Plant are used for Boiling of Raw Paddy to Make Par-Boiled or Boiled Rice.

Paddy Parboiling And Drying Rice Milling Plant Parboiling Tanks, Elevators, High Pressure Fan, Dryer, Heat Exchanger, Pipelines, Valves, etc.

The Steam is generated in the Boiler which is a Integral Part of Parboiling process, but it is considered a Different Section in the RICE MILL UNIT.

Single Stage Automation Paddy Parboiled Rice Mill Milling Production Plant brief introduction:

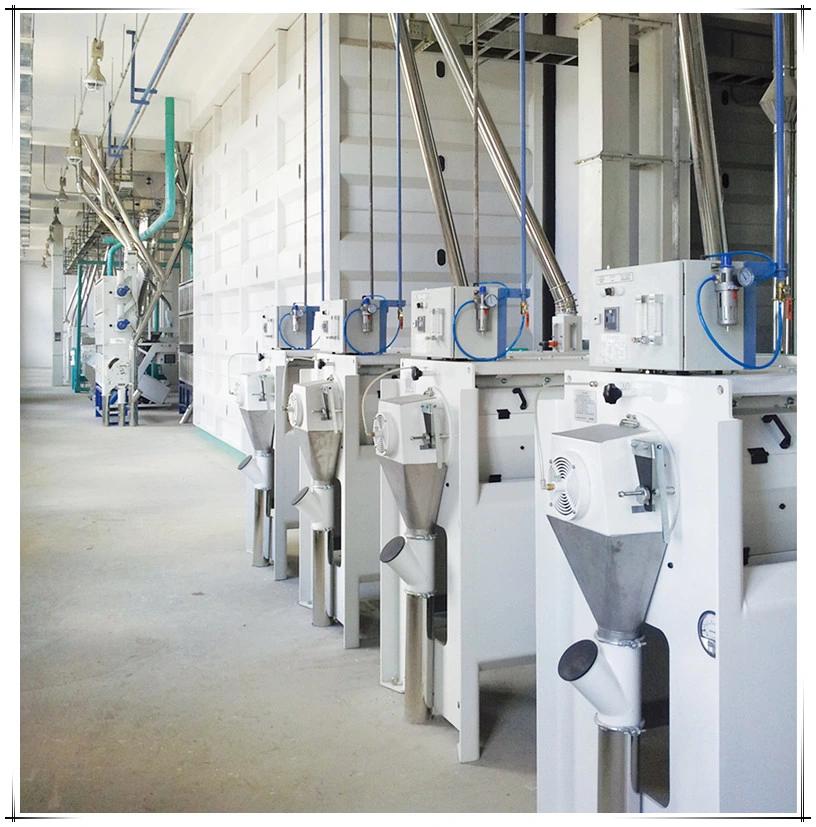

(1)Rice finishes being cleaned by vibrating sieve, destoner and magnetic separator, and then through grinding roller for hulling.

(2)After air blowing, entering milling machine, the paddy finishes the process of husking and milling in succession.

(3)Then husk, chaff, and white rice flour are pushed out of machine respectively.

Single Stage Automation Paddy Parboiled Rice Mill Milling Production Plant process:

| Pre Cleaning | Clean out all impurities and unqualified grains from raw paddy |

| De-stoning | Separate stones, clods from rice |

| Parboiling (Alternative) | Improve the nutritious quality and milling recovery percent during husking, polishing, whitening |

| Husking | Remove husk from rice |

| Husk Separation | Separate husk from brown rice/ unhulled rice |

| Rich Separation | Separate the unhusked paddy from brown rice |

| Whitening | Remove all or part of the bran layer and germ from brown rice |

| Polishing | Improve appearance of milled rice by removing bran and by polishing kernel |

| Color Sorting (Alternative) | Remove foreign matter such as mould, broken rice from milled rice |

| Milling | Mill the pure rice |

Packaging & Shipping

1. Standard wooden case packing with international quality.

2. Reliable shipping agent with long-term cooperation.

If you have any need, please feel free contact with us!