1-3ton/Hour Automatic Paddy Parboiling Rice Milling Plant

Nanjing Zhanyi Technology Co., Ltd.- Warranty:12 Months

- Type:Rice Mill

- Application:Rice flour, Wheat, Rice,Corn,Millet, Sorghum, Buckwheat.Others

- Voltage:380V

- Appearance:Vertical

- Press Materials:Rice

Base Info

- Model NO.:Parboiling rice milling plant

- Press Series:Fourth

- Condition:New

- Customized:Customized

- Capacity:According to Customers′ Need

- Size:According to Capacity

- Factory Visiting:Yes

- Machine Test:Supported

- Transport Package:Seaworthy Wood Case

- Specification:CE, ISO, SGS, CCC

- Trademark:LY

- Origin:Jiaozuo of Henan Province

- HS Code:8437800000

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. Parboiling rice milling plant Press Series Fourth Condition New Customized Customized Capacity According to Customers′ Need Size According to Capacity Factory Visiting Yes Machine Test Supported Transport Package Seaworthy Wood Case Specification CE, ISO, SGS, CCC Trademark LY Origin Jiaozuo of Henan Province HS Code 8437800000 Production Capacity 100 Sets/YearProduct Description

1-3ton/Hour Automatic Paddy Parboiling Rice Milling PlantPaddy Parboiling Rice Milling Plant Specification:

1.)Batch system, open tank with pressure

2.)Continuous pressure cooking system in vertical cooker or horizontal belt cooker

3.)Brown rice parboiling

4.)Laboratory parboiling system for research and test run

5.)Low energy consumption due to efficient design of blowers & elevators

6.)Higher percentage of recovery of rice .

7.)Uniform steaming of paddy made possible by steam distribution system in tanks .

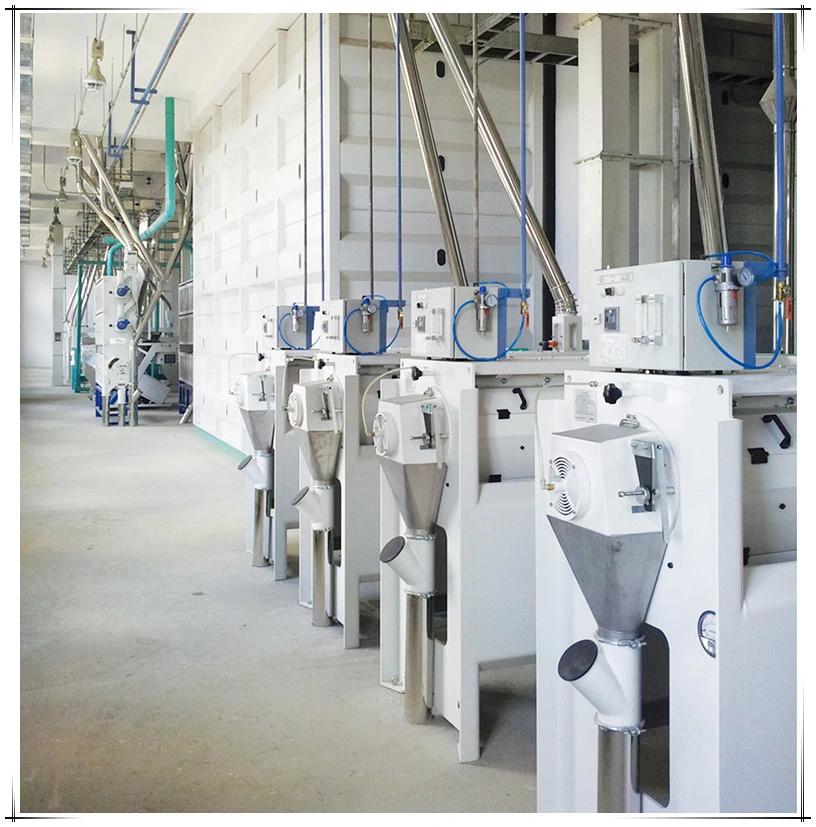

8.)Factory fitted , assembled plant in fully bolting & folding construction .

9.)Lowest losses due to spillage&dropping of grain during process .

10.)Total uniform quality of paddy in terms of cooking & drying.

11.)Two water tanks are provided overhead as cold water easy to lift .

12.)Constant research &development of products by team of engineers & feed back of

customers .

13.)Minimized hidden cost as items within our scope are supplied & arranged by us .

14.)Minimized time taken during installation as 90% of material is manufactured in our

factory

15.)Low labour work force required in running the unit as most of the operations are

automatic .

16.) No spillage as the increased height of plant ensures better flow taper to wet paddy

Paddy Parboiling Rice Milling Plant brief introduction:

(1)Rice finishes being cleaned by vibrating sieve, destoner and magnetic separator, and then through grinding roller for hulling.

(2)After air blowing, entering milling machine, the paddy finishes the process of husking and milling in succession.

(3)Then husk, chaff, and white rice flour are pushed out of machine respectively.

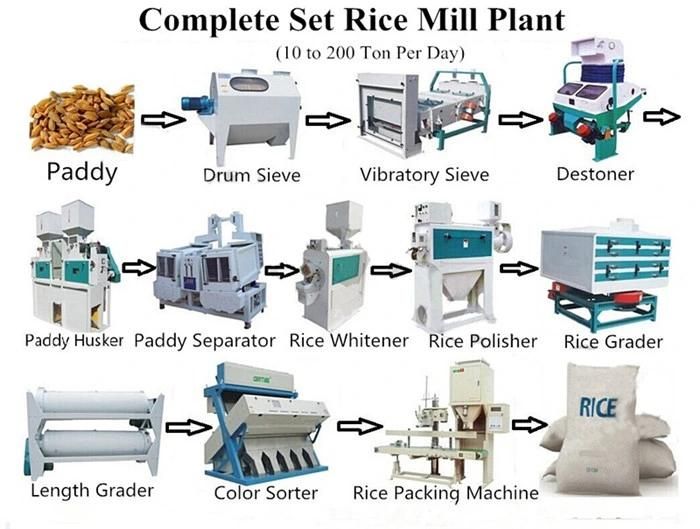

Paddy Parboiling Rice Milling Plant Flow Chart:

Paddy Cleaner→Sorking and Cooking tank→Dryer → Destoner → Paddy husker → Paddy Separator → Rice Whitener → water polisher → Rice Grader → Color Sorter → Packing

Rice Mill Production Line/ Rice Milling Machine process:

| Pre Cleaning | Clean out all impurities and unqualified grains from raw paddy |

| De-stoning | Separate stones, clods from rice |

| Parboiling (Alternative) | Improve the nutritious quality and milling recovery percent during husking, polishing, whitening |

| Husking | Remove husk from rice |

| Husk Separation | Separate husk from brown rice/ unhulled rice |

| Rich Separation | Separate the unhusked paddy from brown rice |

| Whitening | Remove all or part of the bran layer and germ from brown rice |

| Polishing | Improve appearance of milled rice by removing bran and by polishing kernel |

| Color Sorting (Alternative) | Remove foreign matter such as mould, broken rice from milled rice |

| Milling | Mill the pure rice |

Packaging & Shipping

1. Standard wooden case packing with international quality.

2. Reliable shipping agent with long-term cooperation.