Full Downdraught Painting Baking Room for Auto Body Repair

Hangzhou Mig Packaging Co., Ltd.- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Fully Undershot-type

- Heating Mode:Diesel

Base Info

- Model NO.:IT-L8

- Paint Mist Treatment:Dry-type

- Condition:New

- Plenum (Height):600mm

- Extraction:350mm

- Extraction Area:32m2

- Grids Carrying Capacity:900kg,Wheel

- Walls:60mm Rock Wool Walls

- Brightness:>1,500lux

- Air Volume:35,000m3,H

- Empty Loaded Air Speed:0.30m,S

- Heats:Direct Gas Fired Heating System

- Maximum Working Temperature:80 Celsius

- Inverter:Schneider

- Noise:<78 dB

- Warranty:2 Years

- Stack Light:Yes

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:8000 X 4000 X 3000mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

Description

PAINT BOOTHITEMS SPECIFICATIONS Model IT-SUPER-L8 Paint Booth for Car Refinishing Design standard BS EN 13355: 2004+A1:2009

BS EN 60204: 2006+A1:2009 Internal dimensions 8000 X 4000 X 3000mm (L X W X H) External dimensions 8110 X 5760 X 4010mm (L X W X H) Airflow Full Downdraft Plenum (height) 600mm Extraction Through 350mm high raised basement Extraction area 32m2 Grids carrying capacity 900kg/wheel Internal ramp Pneumatic ramp, 1 set Entrance door 3400x3250mm (WxH), 1 set Service door 840x2250mm(WxH), 2 sets Walls 60mm rock wool walls, 1.0mm substrate Ceiling lights (LED) 10 sets, each 6 X 18W, 1,080W total Sidewall lights (LED) 14 sets, each 3 X 12W, 504W total Brightness >1,500LUX Filters Bag filter, high efficiency ceiling filter, floor filter, exhaust filter Intake/Exhaust unit Direct-type turbine fan, 2x11KW, SIEMENS motor Air volume 35,000m3/h Empty loaded air speed 0.30m/s Heats Direct gas fired heating system, ECLIPSE burner Maximum working temperature 80ºC Controls CE standard control box Inverter SCHNEIDER inverter Stack light Yes Rated power 28KW ITEMS SPECIFICATIONS Model Car Prep Station Design standard BS EN 13355: 2004 + A1: 2009

BS EN 60204: 2006 + A1: 2009 Internal dimensions 6850×4000×3350mm (L×W×H) External dimensions 8110×4075×4010mm (L×W×H) Rear wall 50mm rock wool panels Plenum With plenum, 600mm(H) Exhaust plenum chambers 4000*660*800mm Filter areas 3.2m2 Front door 3700x3000mm, 1 set, electric soft curtain door Divider door 5800x3000mm, 1 set, electric soft curtain door Ceiling lighting 8 sets, each 4 X 18W, 576W total Brightness > 700Lux Exhaust system 1×5.5KW, 970RPM, 380V, 50HZ, SIEMENS motor Air volume 18,000m3/h, 650pa Filters High efficiency ceiling filter, pleated andreae filters + fiberglass filter, exhaust filter Controls Soft start, emergency stop switch, lighting,

failure indication Electrical & Tool cabinets Yes. Special item Rated power: 10KW

3.DETAILS

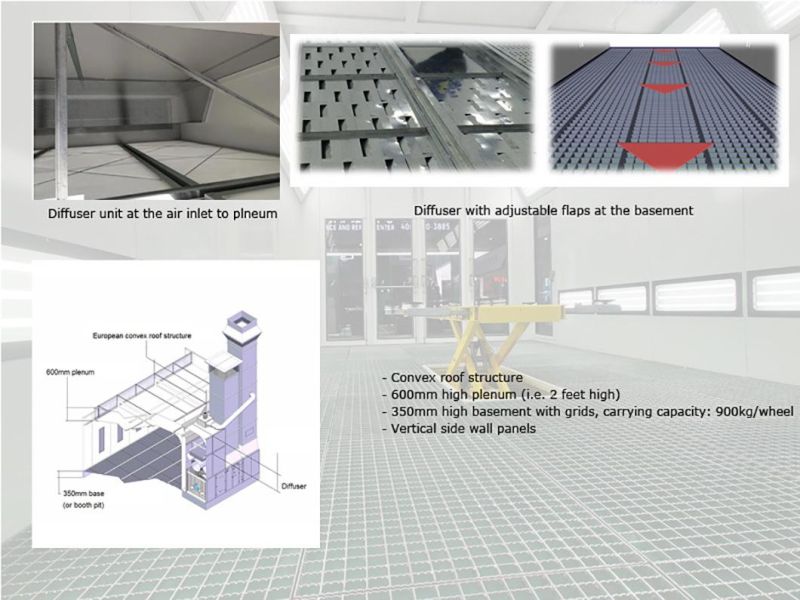

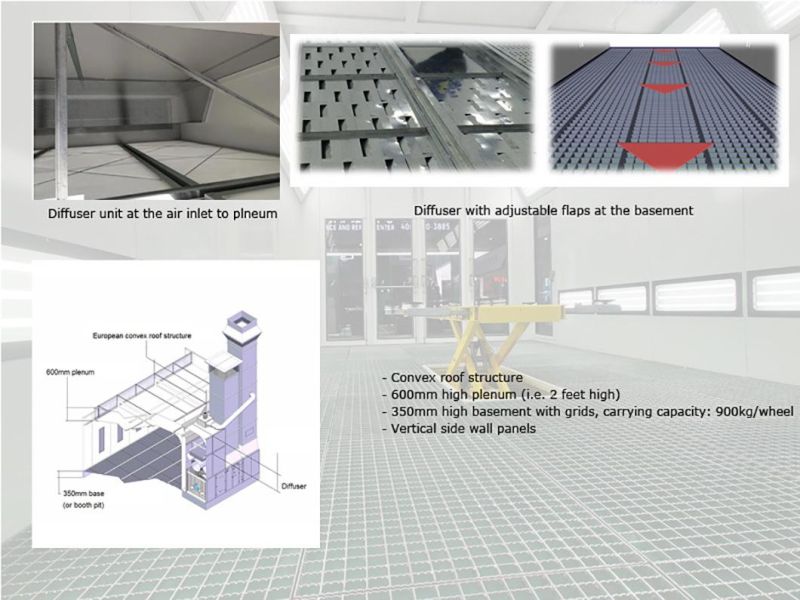

AIRFLOW & BOOTH STRUCTURE (PAINT BOOTH)

1.600mm plenum The plenum comes with diffuser unit, providing the assistance to reduce air speed before air flows to the plenum, which helps achieve even air distribution.

2.Vertical walls.

3.Raised basementThe air flows vertically from the plenum to the workspace, and extracted through raised basement. In the basement, there is also diffuser to for adjusting airflow speed, so the air can be balanced from one end to the other end.

DOORS & LIGHTS

AIR INTAKE AND EXHAUST UNIT

CONTROL

UPGRADE

CAR PREP STATION

- 600mm plenum

- Flat ceiling lighting fixtures

- Exhaust fan unit, 1*5.5kw

- Exhaust plenum chambers at the back

- Electrical and tool cabinets on the rear wall

- Electric soft curtain door in the front and on the side

CONTROL BOX AND TOOL BOX (FOR PREP STATION)

Arrangement: on the rear wall

OPTION

ELECTRIC SOFT CURTAIN DOOR

FAQQ: I want to visit your factory. Where is your office and factory located?A: We are located in Guangzhou, 15 minutes' drive from the airport. Welcome to visit us.

Q: Do you have spray booth sample to show me when I visit you?A: Yes, we have show room here at the factory. Meanwhile, we can also show you spray booth operating at our customers' workshops nearby so you can better learn our products.

Q: What if I meet problems when installing your spray booth?A: Firstly, report the problems to us. We will reply in time and propose the solution to get problems solved. We are always responsible for the products and solution that we provide.

Q: What is the MOQ of your spray booth?A: 1 set.

Q: How long does it take for me to receive the spray booth?A: For standard spray booth, the production lead time is 35 days. The shipping is usually 6 weeks after EXW depending on the destination port.

Q: How long does it take to install the spray booth? And how many people I need?A: For a standard spray booth, usually it can be installed within 10 working days by 3-4 people (including 1 professional electrician).

BS EN 60204: 2006+A1:2009

BS EN 60204: 2006 + A1: 2009

failure indication

3.DETAILS

AIRFLOW & BOOTH STRUCTURE (PAINT BOOTH)

1.600mm plenum The plenum comes with diffuser unit, providing the assistance to reduce air speed before air flows to the plenum, which helps achieve even air distribution.

2.Vertical walls.

3.Raised basementThe air flows vertically from the plenum to the workspace, and extracted through raised basement. In the basement, there is also diffuser to for adjusting airflow speed, so the air can be balanced from one end to the other end.

DOORS & LIGHTS

- 2+2 structure entry door: 3400x3250mm

- Service door with full size tempered glass observation window

- Inclined ceiling and horizontal sidewall lights

AIR INTAKE AND EXHAUST UNIT

- Non-spark fan & SIEMENS motor

- Cycle damper (for spraying and baking phase)

- Direct gas fired heating unit, Eclipse direct fired burner

- 97% efficiency

- Accurate temperature control

CONTROL

- Basic functions: spraying, heating spraying, flash, baking, cooling

- Safety functions: emergency stop, over-heat alarm, failure alarm, fans interlock with heating system

- SCHNEIDER inverter control

UPGRADE

- Traditional control panel with manual buttons

- Automatic pressure adjustment

CAR PREP STATION

- 600mm plenum

- Flat ceiling lighting fixtures

- Exhaust fan unit, 1*5.5kw

- Exhaust plenum chambers at the back

- Electrical and tool cabinets on the rear wall

- Electric soft curtain door in the front and on the side

CONTROL BOX AND TOOL BOX (FOR PREP STATION)

Arrangement: on the rear wall

OPTION

- The servo of central dust extraction unit can be integrated in the control panel

ELECTRIC SOFT CURTAIN DOOR

FAQQ: I want to visit your factory. Where is your office and factory located?A: We are located in Guangzhou, 15 minutes' drive from the airport. Welcome to visit us.

Q: Do you have spray booth sample to show me when I visit you?A: Yes, we have show room here at the factory. Meanwhile, we can also show you spray booth operating at our customers' workshops nearby so you can better learn our products.

Q: What if I meet problems when installing your spray booth?A: Firstly, report the problems to us. We will reply in time and propose the solution to get problems solved. We are always responsible for the products and solution that we provide.

Q: What is the MOQ of your spray booth?A: 1 set.

Q: How long does it take for me to receive the spray booth?A: For standard spray booth, the production lead time is 35 days. The shipping is usually 6 weeks after EXW depending on the destination port.

Q: How long does it take to install the spray booth? And how many people I need?A: For a standard spray booth, usually it can be installed within 10 working days by 3-4 people (including 1 professional electrician).