Beverage Preparation Tank with Mixing Agitator Mixing Tank Holding Tank

NINGBO HAISHU JUDIN PACKING PRODUCTS CO., LTD.- After-sales Service:Online Service

- Warranty:One Year

- Process:Thermal Processing

- Power Source:Electric

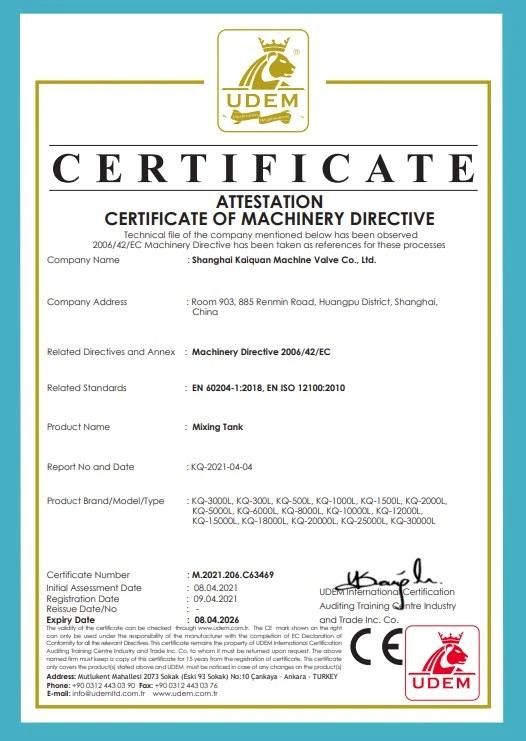

- Certification:CE, MET, CSA, UL, SA8000, ISO9001

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:KQ-100L to KQ10000L

- Application:Milk, Yogurt, Milk Powder

- Customized:Customized

- Name:Beverage Preparation Tank with Mixing Agitator Mi

- Type:Aseptic Tank Set

- Capacity:200L to 20000L

- Mixer Speed:36rpm,60rpm,960rpm,2900rpm

- Mixer Shape:Customized

- Tank Material:SS304,SS316

- Function:Storage, Heating, Cooling, Mixing, Fermentation

- Wroking Life:More Than 10years

- Tank Structure:Single Wall, Double Walls, Insulation Tank

- MOQ:1set

- Spare Parts:Available

- OEM:Yes

- Cleaning:CIP Spray Ball

- Temperature:Sensor

- Level Meter:Yes

- Transport Package:Plywood Box

- Specification:ISO

- Trademark:KQ

- Origin:Shanghai China

- HS Code:8479820090

- Production Capacity:100set,Month

Description

Basic Info.

Model NO. KQ-100L to KQ10000L Application Milk, Yogurt, Milk Powder Customized Customized Name Beverage Preparation Tank with Mixing Agitator Mi Type Aseptic Tank Set Capacity 200L to 20000L Mixer Speed 36rpm,60rpm,960rpm,2900rpm Mixer Shape Customized Tank Material SS304,SS316 Function Storage, Heating, Cooling, Mixing, Fermentation Wroking Life More Than 10years Tank Structure Single Wall, Double Walls, Insulation Tank MOQ 1set Spare Parts Available OEM Yes Cleaning CIP Spray Ball Temperature Sensor Level Meter Yes Transport Package Plywood Box Specification ISO Trademark KQ Origin Shanghai China HS Code 8479820090 Production Capacity 100set/MonthProduct Description

Beverage Preparation Tank with Mixing Agitator Mixing Tank Holding Tank

Stainless Steel Double Wall heating and mixing tank

Jacketed tank with mixer,

Choice of simple jacket tank (simple skin) or of retention double jacket tank (double skin) or tank and retention

a jacketed vessel is a container that is designed for controlling the temperature of its contents, by using a cooling or heating "jacket" around the vessel through which a cooling or heating fluid is circulated

hot water heating tank with mixer; hot water tank with mixer

Heating and mixing tank

preparation tank/mixing tank for dairy production line,, Shanghai, China (Mainland)

The dairy preparation thus obtained is conveyed to storage tanks where it is also subjected to continuous stirring,

because a typical dairy plant might manufacture yogurts, drinks and cheeses tanks . Our sanitary dairy mixing tanks could encompass the entire plant and all products, or we could create a partition between processes if it is possible to separate resource usage, raw materials, and so on. We make the assumption here that these different processes are independent and so decide to focus on the yogurt process

1.Mixing tank(sterilizing tank /aseptic tank) is made of SUS304 Or SS316L

2.Mixing tank(sterilizing tank /aseptic tank) can used for heating or coolling using dimple jacket.

3.with perlite or PU to keep heat /cold insulate.

4.All angles is treated in special process to guarantee no dead angle

5.this tank is widely used for heating or cooling or temperature holding

6.liquid foods like milk, juice, ice cream, chemical and biological areas.

7.With agitation or no can be an option, and it can be build according to the customer detail requirement.

Mixing tank(sterilizing tank /aseptic tank) Standard configuration:

manhole, thermometer with figure display, ladder, CIP washing point, pull pole valve, controllable trestle, charging/discharging port and sampling valve etc.

Other Types are according to customer's requirement

If you are interested in this product ,please contact with me :

| (mm) | D1(mm) | H1(mm) | H2(mm) | H3(mm) | δ (mm) | DN(mm) | |

| KQ 100 | 400 | 600 | 400 | 1050 | 250 | 3 | 32 |

| KQ 150 | 400 | 600 | 400 | 1450 | 250 | 3 | 32 |

| KQ 200 | 500 | 700 | 400 | 1450 | 250 | 3 | 32 |

| KQ 300 | 600 | 800 | 400 | 1450 | 250 | 3 | 32 |

| KQ 500 | 800 | 1000 | 500 | 1350 | 330 | 4 | 40 |

| KQ 600 | 800 | 1000 | 500 | 1550 | 330 | 4 | 40 |

| YRV1000 | 1000 | 1200 | 700 | 1750 | 330 | 5 | 40 |

| YRV1200 | 1000 | 1200 | 700 | 1950 | 330 | 5 | 40 |

| YRV1500 | 1100 | 1300 | 700 | 1950 | 330 | 5 | 40 |

| KQ 2000 | 1400 | 1600 | 700 | 1650 | 3360 | 5 | 40 |

| KQ 2500 | 1400 | 1600 | 800 | 2000 | 330 | 5 | 40 |

| KQ 3000 | 1500 | 1700 | 800 | 1900 | 330 | 6 | 40 |

| KQ 4000 | 1700 | 1900 | 900 | 2100 | 330 | 6 | 40 |

| KQ 5000 | 1700 | 1900 | 900 | 2850 | 400 | 6 | 50 |

| KQ6000 | 1800 | 2000 | 1000 | 2850 | 400 | 6 | 5 |

Beverage Preparation Tank with Mixing Agitator Mixing Tank Holding Tank .