Fully Automatic Plastic Chair Bus Seat Extrusion Blow Molding Machine Price

Zhejiang Tengmei Industry and Trade Co., LtdBase Info

Description

Overview

Product Parameters

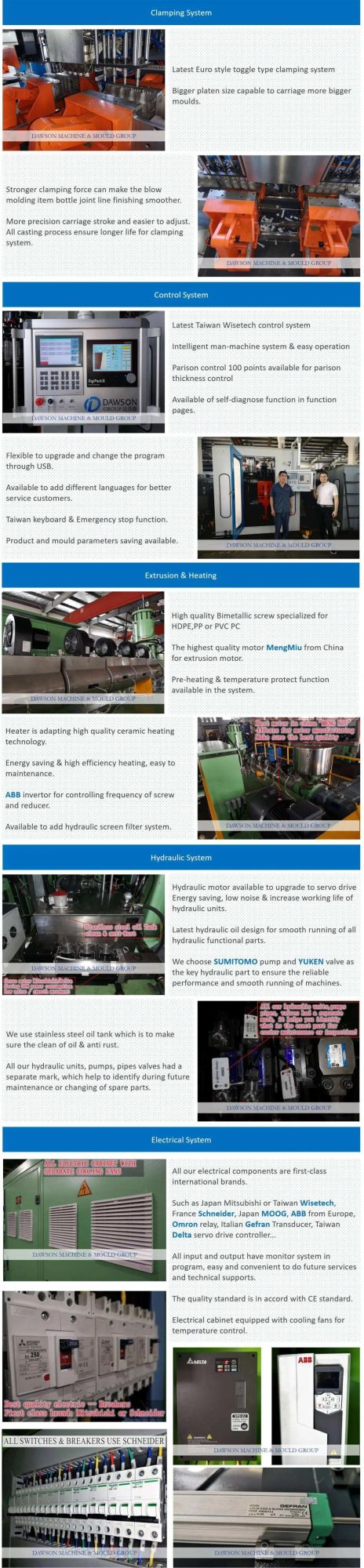

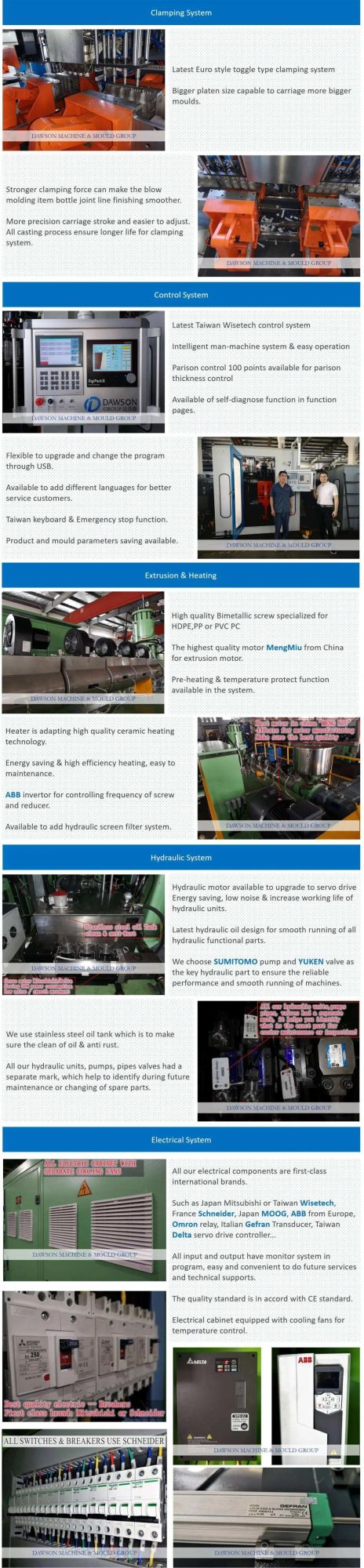

extruder1 Screw diameter 100mm 2 L/D ratio 24:1 3 Screw speed 15~50r.p.m. 4 Drive motor 45Kw 5 Heating zone with cooling fan 6 zone 6 Output/Capacity 170 Kg/hr(HDPE particle) 8 Heating capacity 25.1 kw 9 Vertical adjustment of head 500mm 10 Forward/Backward adjustment of head 500mm 11 Groove feed barrel cylinder Have IKV 12 Gear box Hard gear decelerator 13 Ladder and safety rails Have Accumulator Head 1 Accumulator capacity 20L(15kgHDPE) 2 Design First in and first out 3 Heating zone 6 zone 4 Heating capacity 25.1kw 5 Max die&pin diameter 450mm 6 Die head axis with pre-blow Ø120mm 7 Accumulator push-out stroke measurement Transducer Italy Gefran 8 Injection pressure 12 Mpa 9 Extruder stop Have CLAMPING UNIT 1 Tie bar Two tie bar 2 Platen size 900(W)X1400(H) 3 Length of mold 900-960mm 4 Clamping force 780KN 5 Close/Open stroke 880-1700mm 6 Mold weight Max. 5000 kg 7 Clamping stroke measurement Transducer Italy Gefran 8 Hydraulic valve Taiwan Hitech 9 Number of hydraulic cylinder 1 10 High pressure 14 Mpa 11 Support parts for platen movement Liner Guide HYDRAULIC SYSTEM 1 Main motor/vice motor AC15Kw/15Kw 2 Hydraulic valve Taiwan Hitech 3 Hydraulic pump Taiwan Hitech 4 Oil tank capacity 850L 5 Operating pressure 12 Mpa 6 Cooling water for oil fixed 7 Control of oil level be observed dipstick PNEUMATIC SYSTEM 1 Operating pressure 0.8 Mpa 2 Blow pressure 0.8 Mpa 3 Needle blow circuit High & low pressure 4 Intermittent blow Have 5 Controlled support air for parison Have 6 Air Valves AIRTAC 7 Quick exhaust for support air Have PARISON CONTROL 1 Programmer JAPAN MOOG 2 Servo valve

MOOG

3 Servo cylinder Intergret of die head 4 Hydraulic pack

TAIWAN YOSHE Variable Displacement Piston Pumps

ELECTRICITY 1 Contactor

Schneider

2 Total connected load (approx.)

114kw/h 3 Average energy consumption (approx.)

42 kw/h WATER COOLING 1

Machine water consumption

6000L/h 2

Mold water consumption

6000L/h AIR CONSUMPTION 1 Compressed air consumption 1.2 kgf/cm2, 3000 L/min OTHER FEATURES 1 PLC control MITSUBISHI 2 Human machine interface Hitech 3 Recipe storage in hard disk Available HEATING CONTROL 1 Power supply to heating element Relay + Contactor Japan Omron+Korea LG 2 Control PLC controle 3 Type of thermocouple K Type 4 Adjustable lower and upper limit alarm Have 5 Cold start prevention for screw Have 6 Alarm for thermocouple and heating element breakage Have, heating element breakage by anperemeter 7 Pre-heating function Have Die-ring AND Die-pin 1 one sets of die & pin One set according to customer 2 Test material Buyer supply 300kg material to seller for machine testing OPTION 1 Bottom blow (hydraulic) and sealing unit (pneumatic) Double blow pin (including expand & up-down & parison seal) 2 Robot Have 3 Machine Dimension 6.8×3.3×5 4 Total weight 20

High quality mould After Sales Service

After Sales Service

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong

International Airport. We can

pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with

quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical

support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers

products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the

customer's employees.

Q: What's DAWSON's advantage?

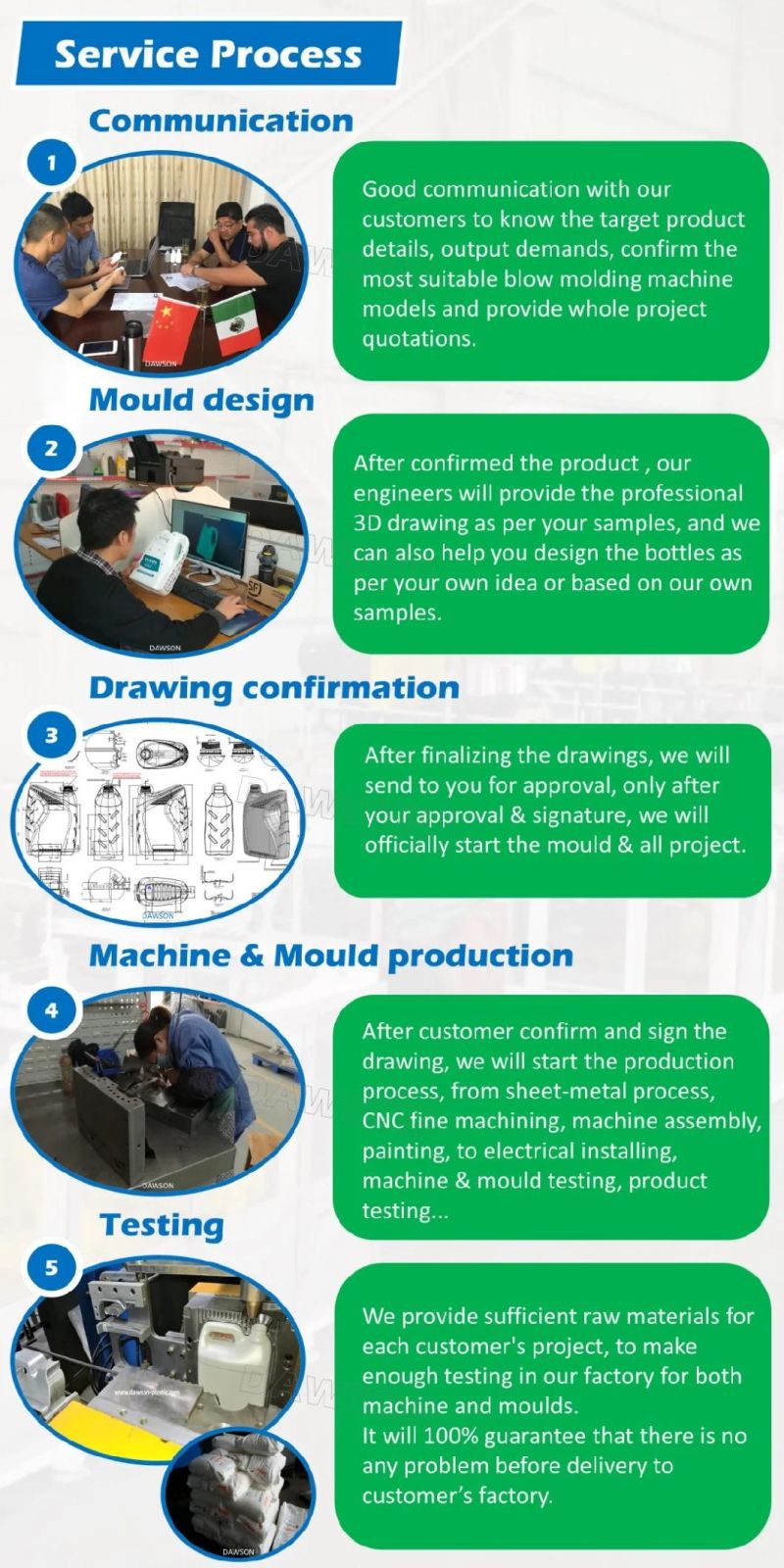

DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we

can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save

a lot of cost and time.

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

extruder

MOOG

Machine water consumption

Mold water consumption

High quality mould

Company ProfileCustomer Feedback

After Sales Service

After Sales Service

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong

International Airport. We can

pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with

quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical

support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers

products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the

customer's employees.

Q: What's DAWSON's advantage?

DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we

can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save

a lot of cost and time.

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!