Price of Plastic PE PP Foam Sheet Extrusion Machine in China, Single Lay or Trilayer.

Xinzheng Lifa Abrasives & Abrasives Co. LtdBase Info

Description

Basic Info.

Model NO. LMSB-6533, 75/33, 90/33, 120/33, 120/36, 150/33 Customized Under The Order Condition New Die Head Design T-Type Die Head-Jc-Times Brand Usual Sheet Width 500-2200mm Application Packaging, Stationery, Chemicals Main Electrical Components ABB, Rkc, Ormorn, Schnider, Delix etc Usual Sheet Thickness 0.5-2mm, 1.5-10mm, 3-30mm, 6-20mm Extruder Design Conical Single Screw Extruder Terms of Delivery Fob, CIF, CIP, DDP, EXW Output 120kg-1000kg Payment System Prepayment 30%+Balance 70% Production Time 60 Days Transport Package Wooden Cases with Vacuum Film Specification LMSB-6533, 75/33, 90/33, 120/33, 120/36, 150/33 Trademark Leader Machinery Origin Qingdao of China HS Code 8477209000 Production Capacity 100 Sets/YearProduct Description

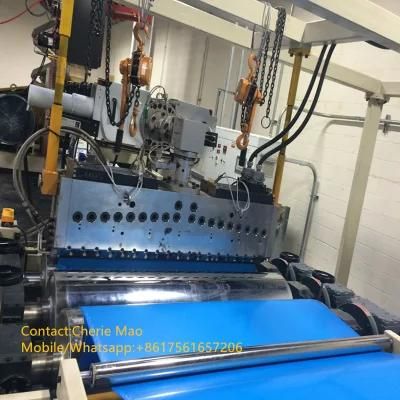

PP PE foam sheet extrusion line SHEET EXTRUSION LINE CONSISTS OF :

- Vacuum Feeding Machine.

- Single- Screw Extruder.

- T-Type Die Head.

- Three-roller Calendar.

- Cooling Frame.

- Edge Cutting Machine.

- Hauling off Machine.

- Knife Cutting Machine.

- Stacker.

PP PE foam sheet extrusion line extruder machines plastic

This line specially used for producing PP/PE/PS/ABS single layer or multi-layer sheet or plate, suitable in the fields of packing, stationery, chemicals, construction, household appliances and so on.

Sheet specifications:

Usual sheet width: 700,900,1020,1200,1300,1400,1500,1700,1800,2100,2200mm

Usual sheet thickness: 0.5-2mm, 1.5-10mm, 6-20mm,3-30mm

Main technical data:

1,Extruder: Screw adopts special mixing function and high plasticizing capacity design, famous imported world-known thermocontrollers,electronics, hard gear surface gearbox to ensure high effective material extrusion capacity.

2,T-type die head: excellent mould special steel 5CrNiMo, suitable compression ratio to ensure uniform flow stability. Using a special double flow design which allows more precise adjustment to sheet thickness. Temperature control of plus or minus 1 ºC can accurately control the plasticizing process and sheet thickness.

3,Three roller calendar: According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar. Internal roller temperature control adopts a unique flow channel, so that the stability if uniform distribution roller. The independent oil temperature control for three roller calendar to ensure more stable and exact control.

4,Cooling frame: according to product specifications, configure with different specifications of stainless steel cooling roller.

5,Edge cutting device: trimming can be manual or automatic. Both the position of the edge trimmer and the width of trimming sheet can be adjustable.

6,Cutting machine: it can be divided into saw cutting or knife cutting. Thin type and non-friable type sheet usually adopt knife cut, adopting high quality alloy cutting tools, sharp and durable. Thick type sheet usually use saw cutting.

7,Winder: torque motor driving. The winding speed can be automatically controlled according to the tension. Portable airshaft, easy and convenient operation.

Contact: Cherie Mao, Mob. +8617561657206