PVC Pipe Extruding Plastic Machine

Taizhou Vast Sea Trading CompanyBase Info

Description

Basic Info.

Model NO. mengkwa-GF Certification CE Customized Customized Condition New Export Market Global Application PVC Pipe Color Customized Brand Mengkwa Products Raw Material PVC Transport Package Export Standard Packing, Wood Case Specification CE, ISO Trademark Mengkwa Origin Zhejiang, China Production Capacity 180-750 Kg/HrPackaging & Delivery

Package size per unit product 1.00cm * 1.00cm * 1.00cm Gross weight per unit product 1.000kgProduct Description

UPVC/CPVC Pipe Extruder Line/MachineApplication and feature:

1.This series plastic pipe production line is mainly used in the area of agricultural, architectural irrigation and drainage system, cable pavement, etc.

2.Total line consist of plstic extruder, mould, vacuum calibrating tank, haul-off unit, cutting unit, stacker, etc.

3.According to different size of pipe, the haul-off unit can be two claws, three claws, four claws, six claws, eight claws, etc.

4.The cutting machine can be saw cutting or planetary cutting.extrusion machine are special equipments which can extrude and mold by using various kinds PVC powders. 5.Equipped with different kinds of molds and auxiliary machines, it can produce various PVC pipes, profiles, sheets, plates, bars and granulation.UPVC pipe extrusion line , CPVC pipe plastic extruder machine is used to produce UPVC or CPVC pipe.

6.Our PVC series plastic pipe production line is mainly used in the manufacture of the plastic PVC pipes with various tube diameters and wall thickness in the aspects such as the agricultural and constructional plumbing,cable laying etc

This line is widely used in producing HDPE water, gas supply pipe. Its features compact structure, highly automation and stable performance.

1. The optimum spiral structure feeding throat highly improves the output of extruder

2. Accurate temperature control system ensures materials melting performance

3. Unique screw design achieves better plasticizing and high quality products

4. Precisely designed gearbox with a high torsion guarantees stable running

5. "H" shape frame to decrease vibrating of extruder

6. Advanced PLC operation system realizes synchronization and automation

7. Adopt automatic water temperature & level control and special independent filters on both vacuum and cooling tanks

8. Offer stable haul-off unit with 2-12 caterpillars

9. Provide saw & chip-free cutting options

10. Low energy consumption, excellent performance, and easy maintenance

Model number | PVC-16/63 | PVC-20/110 | PVC-50/160 | PVC-75/250 | PVC-110/315 | PVC-200/450 | PVC-315/630 | PVC-500/800 |

Pipe diameter | 16-63mm | 20-110mm | 50-160mm | 75-250mm | 110-315mm | 200-450mm | 315-630mm | 500-800mm |

Max output | 120kg/h | 120kg/h | 180kg/h | 300kg/h | 450kg/h | 650kg/h | 800kg/h | 1400kg/h |

Production rate | 1.5-15m/min | 0.8-8m/min | 0.5-5m/min | 0.4-4m/min | 0.3-2m/min | 0.1-1m/min | 0.07-0.7m/min | 0.05-1 m/min |

Extruder model | SJZ-50/105 | SJZ-50/105 | SJZ-55/110 | SJZ-65/132 | SJZ-80/156 | SJZ-92/188 | SJZ-92/188 | SJZ-105/220 |

Installed power | 45kw | 45kw | 55kw | 75kw | 105kw | 160kw | 205kw | 305kw |

Center height | 1000mm | 1000mm | 1000mm | 1000mm | 1100mm | 1100mm | 1200mm | 1350mm |

Installation area | 22*2.5*2.0m | 24*2.8*2.0m | 24*2.8*2.0m | 30*2.8*2.2m | 35*3.0*2.4 m | 36*3.0*2.4 m | 38*3.2*2.8 m | 42*3.5*3.2 m |

Ningbo Mengkwa Machinery Co.,Ltd is an experienced and professional manufacturer of plastic extruder and extrusion lines for years. We can produce various equipments, including plastic pipe extrusion lines, plastic profile extrusion lines, plastic sheet/plate extrusion lines and also some recycling and pelletizing machines etc. According to different requirement s of each customer, our engineers will provide most professional mechanical design and manufacturing, and the complete processing technology to meet their special application requirements.

Ningbo Mengkwa Machinery Co.,Ltd is an experienced and professional manufacturer of plastic extruder and extrusion lines for years. We can produce various equipments, including plastic pipe extrusion lines, plastic profile extrusion lines, plastic sheet/plate extrusion lines and also some recycling and pelletizing machines etc. According to different requirement s of each customer, our engineers will provide most professional mechanical design and manufacturing, and the complete processing technology to meet their special application requirements.If you want to know any information about us and machine or equipment, please contact with us at any time .

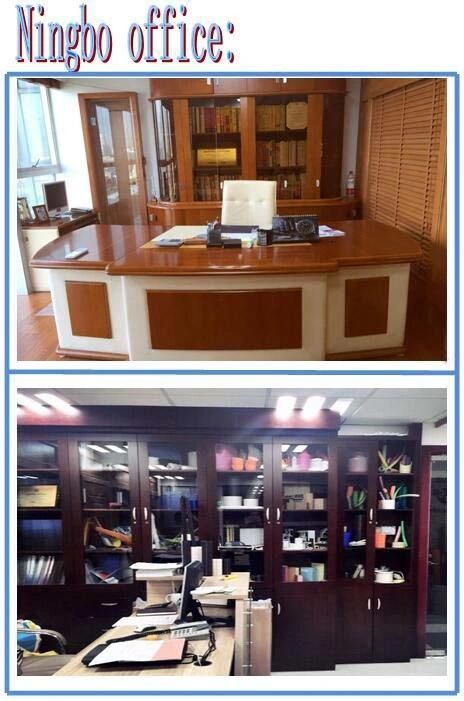

Ningbo Mengkwa Machinery Co. Ltd

Ningbo, China

web: mengkwa.en.made-in-china.com

mengkwa.en.made-in-china.com

After-sale service

1. 24 hours technical support by email, call, video.

2. Warranty for one year after 12 months of shipment

3. Installation and commissioning engineer will provide the tech long machine, and machine operation of the buyer's personnel on-site training, troubleshooting and machine maintenance. The factory offers free installation training for a week the company engineers, beyond a week, the salaries borne by the customer engineer the factory.

Terms of payment

1.after receiving the deposit 40%, our company will arrange production;

2.After the customer check and accept compression machine, before delivery, customer need to pay off the balance payment;