Base Info

Description

Basic Info.

Model NO. HSD Assembly Structure Separate Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Part2 Adhesive (EVA) Coating Line Part1 Basic Film Extrusion Line Transport Package Standard Package Specification ISO9001: 2008 Trademark HSD Origin Qingdao HS Code 8477109000 Production Capacity 10 Units/YearProduct Description

PE Heat Shrinkable Sleeve PE Heat Shrinkable extruder MachineryCross-Linked Polyethylene Heat Shrinkable Sleeve Extrusion Line

The heat shrinkable sleeves mainly used on pipe anti-corrosion, sealing material, repair ect. the pipe includes 3 layer PE steel pipe, directly buried pre-insulated pipes.HDPE corrugated pipe and U-PVC pipe.

this extrusion line has won several National Paterns.

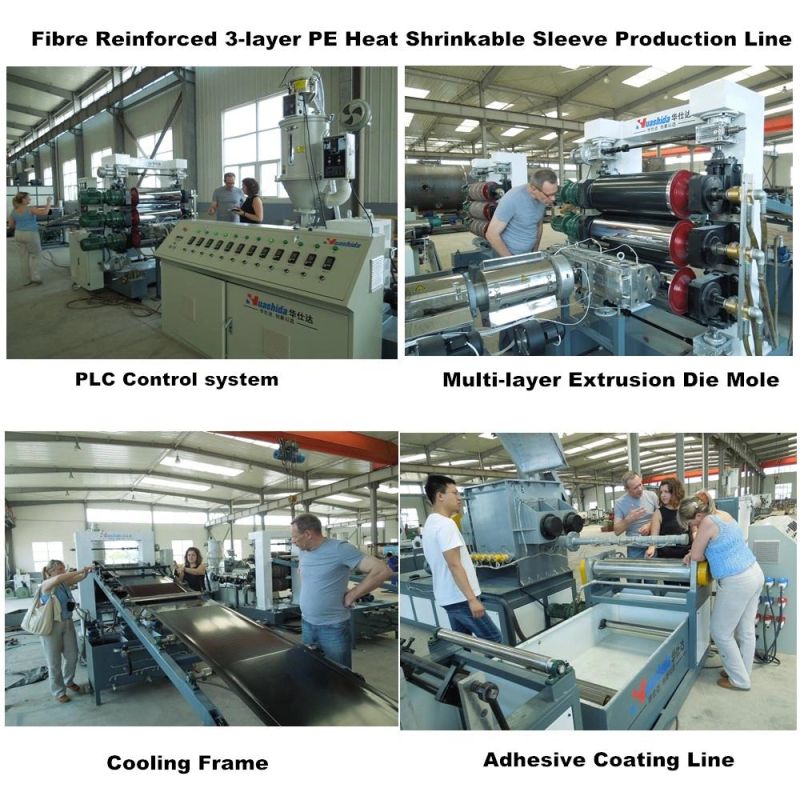

The heat shrinkable sleeve production line composed by Heat shrinkable sleeve basic film extrusion line and Adhesive coating line.

Heat shrinkable sleeve basic film extrusion line:

The line is mainly used for the production of heat shrinkable sleeve substrate.With the unique design T-die mold, It can produce a variety of sheets and plates.Daily output is 2-4 tons.

Adhesive coating line:

1.Unique design of the reactive mixing machine, coating and tensile integration, stable and reliable performance.

2.Specific technical line drawing, stretching equipment without expensive cost and complex procedures.

3.Stable equipments, mature technology, the output rate of heat shrinkable than the two-step with the cost savings of more than 30%.

PE Sheet Extrusion Line

EVA Gluing machine

PE Heat Shrinkable Sleeve for kinds of Pipes

| Model | Thickness | Wide | Speed | Capacity | Installed capacity |

| SJ65/650 Model | 0.5-2mm | 70-650 | 0-5m/min | 150kg | 90kw |

| SJ90/1200 Model | 0.5-1mm | 300-1200 | 0-8m/min | 300kg | 160kw |