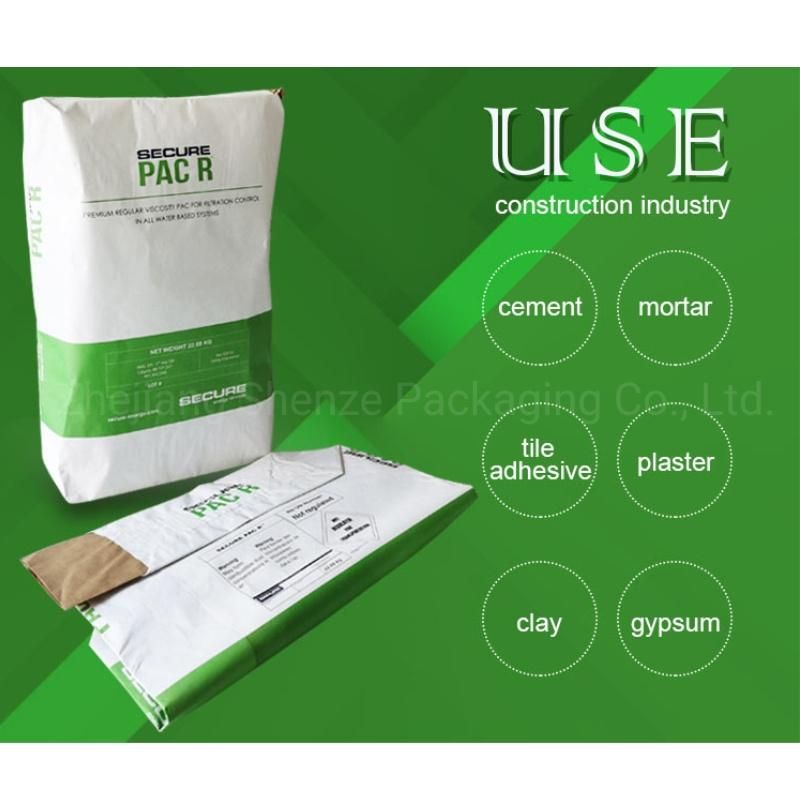

54*63 Cm Putty Powder White Kraft Paper Valve Bag

Zhejiang Shenze Packaging Co., Ltd.- Feature:Moisture Proof, Recyclable, Bio-Degradable, Shock Resistance, Antistatic

- Material:Paper

Base Info

- Specification:25-50kg

- Transport Package:by Pallets & Cloth Bag

- ODM & OEM:Supported

- Bag Size:Customized

- Printing:Customized

- Valve Type:Inner Valve&Outer Valve

- Bag Weight Capacity:10-50kg

- Bag Variety:Upright Bag

- Raw Materials:Kraft Paper

- Making Process:Composite Packaging Bag

- Shape:Square Bottom Bag

- Model NO.:SZVB-500-50

- Trademark:SZ

- Origin:Wenzhou

- HS Code:4819400000

- Production Capacity:200000000

- Package size per unit product:80.00cm * 60.00cm * 28.00cm

- Gross weight per unit product:40.000kg

Description

| Product Name | Multiwall Kraft Paper Bag |

| Other Names | Valve Bag,Cement Bag,Packaging Bag |

| Bag type | Central seal type,seal on the bag back |

| Raw Material | 1. Multi layer kraft paper 2. Kraft paper + PE layer 3. 100% new PP Material 4.pp woven compound As per customers' requirement |

| Normal Standard Size | 45 x 52 x 10 cm (25kg) / 50 x 65 x 10 cm (50kg) or as request |

| Application | Packing cement. industrial raw material, cement, flour ,Powder, granular and schistose products of building material and chemical etc. |

| Printing (optional) | 1. Offset Printing (economical) 2. Flexo Printing (deluxe) 3. Colorful BOPP Printing (luxury) |

| Bag Top Design | 1. Whole top opening 2. Outer valve opening 3. Inner valve opening |

| Bag Bottom | Square bottom or Hemmed or Sewn |

| Packing | 200 pcs /bale, Customized& by pallets |

| Bag Width | Normal between 350---750mm,According to customer's demand |

| Bag Length | Normal between 300~1360mm,According to customer's demand |

| Bottom Width | Normal between 80-210 mm,According to customer's demand |

| Glue used | PP & HDPE, (white & coloured material) |

| GSM | 70gsm to 100gsm per your requirement |

Our other products you may like:

---Plastic woven laminated paper bag

---BOPP Film Coating plastic woven bag

---BOPP Film Coating plastic woven bag ---Plastic Woven Bag

---Plastic Woven Bag

Production process technology

We are the manufactuer with full set of the equipments(Including detecting,plastic woven fabric drawing and weaving, laminating,bag shaping and making,drop testing, packing delivery etc.) and we have strict QC controll in every production process.

| Bag inner liner | Hot melting crossing pasted&Crossing Pasting |

| Bag Top | 1).Open mouth, Heating & Cold cutting2).For making valve bag,Top pasted with valve(Outer valve&Inner Valve) |

| Bag Bottom | 1).For sewn bags: Inner film heating seal, sewing and glue tape covering Also support sewn lines at outside single or double folded , single or double sewing 2).For valve bags&square bottom bags: We making it by machine,using pasting method |

| Material selecting | Basing on customer's sample bag and requirement. We will give the matched material suggestion. Every type material choosed will be after a series strict quality inspection like testing tension, smoothness, structure, gram, white degree etc. |

| Printing | All type flexo & offset printing pattern can be printed in our factory |

| Features | UV-protection, moisture proof,ultrasonication |

| Perforating | PVC perforating,full perforating etc.According to customer's demand |

Anything more you want to know?

| Trade Terms | CIF,FOB,CRF,EXW etc. |

| Packing | By pallet & by cloth bale.customized.For example:200pcs/ bale |

| Sample | available for free,freight collected |

| Delivery time | Normal 10-15 days after receiving deposit.According to quantity,production season. |

| Payment | T/T, Paypal, L/C etc. |