ISO/Ts16949 OEM Sintered Gear for Electric Tool/Spur Gear /Sun Gear /Gear for Reducer Gearbox/Sintered Pinion

Qingdao Yanfei Rigging Co., Ltd.- Application:Motor, Electric Cars, Machinery, Marine

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Sintered Gear

- Toothed Portion Shape:Spur Gear

- Material:Stainless Steel

Base Info

- Type:Circular Gear

- Density:6.4-7.4 g,cm3

- Apparent Hardness:20-43 HRC

- Tensile Strength:1250 MPa Max.

- Surface Treatment:Steam Oxidation

- Surface Finish:Steam Oxidation

- Transport Package:PE Bag, Bubble Bag, Carton, Pallet

- Trademark:HLXCL

- Origin:China

- Production Capacity:5000000pieces,Year

Description

Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - PackingSurface Treatment High frequency quenching, oil impregnation Apperance No crumbling, cracks, exfoliation, voids, metal pitting and other defects Application Industry,Vehicle, Power Tools, Motor, Bicycle, Electrombi

Why Powdered Metals?Significant cost savings.

Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials

Certification

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

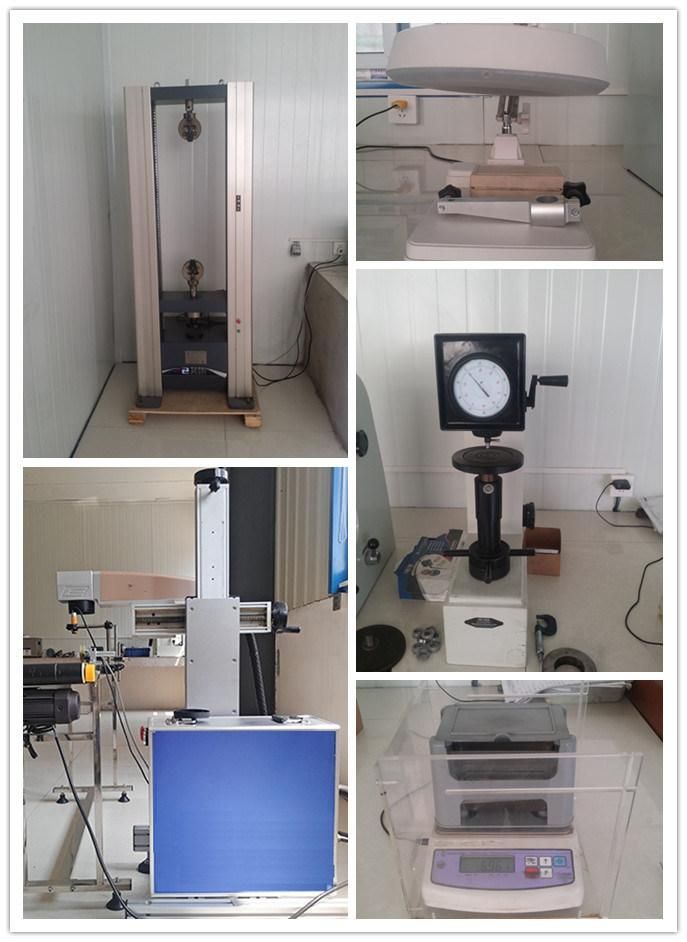

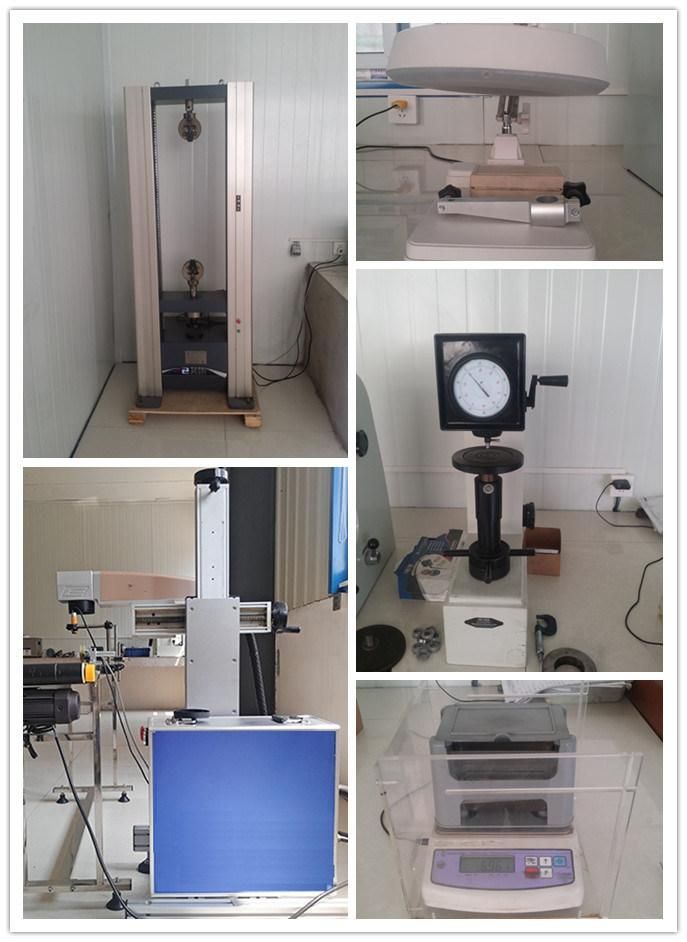

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Please Send us your 2D or 3D drawings to start our cooperation!

Why Powdered Metals?Significant cost savings.

Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials

Certification

A trained, qualified, and dedicated work force

- Engineering is our strength - we will help your designers convert your parts to cost-effective powdered metal parts.

- Every employee is trained to a standard of excellence.

Quality is designed into the process

- Consistent and committed attitude to quality first.

Critical characteristics are measured and controlled using the latest statistical methods

- Quality is always the first priority.

- Our subcontractors are held to the same high standards.

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Please Send us your 2D or 3D drawings to start our cooperation!