Cat365bl Slewing Ring Bearing with Internal Gear

Right Team Holding Ltd.- Rolling Body:Ball Bearings

- The Number of Rows:Single

- Outer Dimension:200-6500mm

- Material:50mn, 42CrMo

- Spherical:Non-Aligning Bearings

- Load Direction:Axial

Base Info

- Model NO.:CAT365BL

- Separated:Unseparated

- Brand:Lyhy

- Testing:in House or Third Party

- Custom Design:Available

- Company History:Since 1993

- External Diameter:1526mm

- Internal Diameter:1235mm

- Height:122mm

- G.W.:450kgs

- Gear:Internal Gear, Gear Hardened

- Delivery:Stock

- Transport Package:Wooden Box

- Specification:ISO2001: 9008

- Trademark:LYHY

- Origin:China

- HS Code:848210900

- Production Capacity:600PCS Per Year

Description

why choose LYHY excavator slewing bearing

1. Best quality and price

2. Small order accepted

3. ISO certified company

4. Variorum models

5. Extensive stock available

6. OEM accepted

Introduction of LYHY excavator slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

Excavator slewing bearing is a special slewing ring bearing as per its applications. And it is a very important part for excavators, we can supply excavator slewing bearings for both second-hand excavators for maintenance and new excavators.

Structure:

Excavator slewing bearing are usually made as per single row ball slewing bearing structure, and most of them are internal gear types, but some are external gear types.

Features

Excavator slewing bearings have familiar features as single row ball slewing ring bearings.

Compact structure, light weight and easily installment.

Application

Excavator slewing bearings are widely used for all brands of excavators, such as Komatsu, Hitachi, Kobelco, Sumitomo, Doosan, Hyundai, Samsung, Caterpillar, Daewoo, Kato, Volvo, Liebherr and so on.

Packaging Details for LYHY excavator bearings

1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to invoid the rust or the moist;

4. We can depend on the customers demand to be packed;

Company Introduction

About LYHY bearings

1. Introduction: we are a manufacturer of slewing bearing since 1993; our factory occupies an area of 30000 square meters with 4 workshop and 1 office building.

2. Featured products: slewing bearing and slewing drive

3. Capital: Current is 1 million RMB, but we are increasing the capital to 10 million RMB

4. Workers: 80

5. Certificate: ISO9001:2008, 3.1 certificate, CCS certificate, Science and Technology Progress Award

6. Annual Exportation: 7million USD

7. Exported countries: (40)

Asia: India, Pakistan, Iran, Signore, Georgia, Malaysia, Vietnam, Thailand, Philippines, Israel, Korea, UAE, Sri Lanka, Saudi Arabia,

Europe: Turkey, Russia, Spain, Czech Republic, Italy, Poland, Slovakia, Bosnia and Herzegovina, Austria, France, Germany, Switzerland, Finland, Ukraine, UK, Portuguesa

America: USA, Canada, Mexico, Brazil, Puerto Rico, Peru, Chile,

Africa: South Africa, Egypt

Oceania: Australia

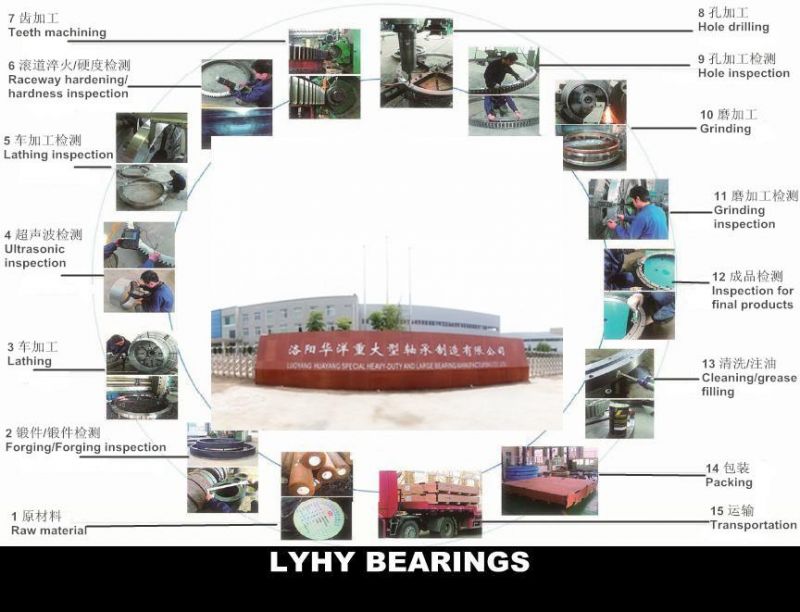

Product Process of slewing bearing, excavator slewing bearing, crane slewing bearing