90 Degree Angle Grease Fitting Pillow Block Bearing (UCFL204)

U&Me Pack Co., Ltd.- Aligning:Aligning Bearing

- Separated:Separated

- Rows Number:Single

- Raceway:Deep Groove Raceway

- Material:Bearing Steel

- Bearing Block Model:F

Base Info

- Model NO.:UCFL203 UCFL204 UCFL205 UCFL206 UCFL207 UCFL208

- Company Scale:70000+Sqm

- Size:mm,Inch

- Color of Housing:Grayish Grey

- Lubrication:Grease, Oil

- Hardness of Bearing:HRC60-63

- Steel Ball Grade:G10 & G16

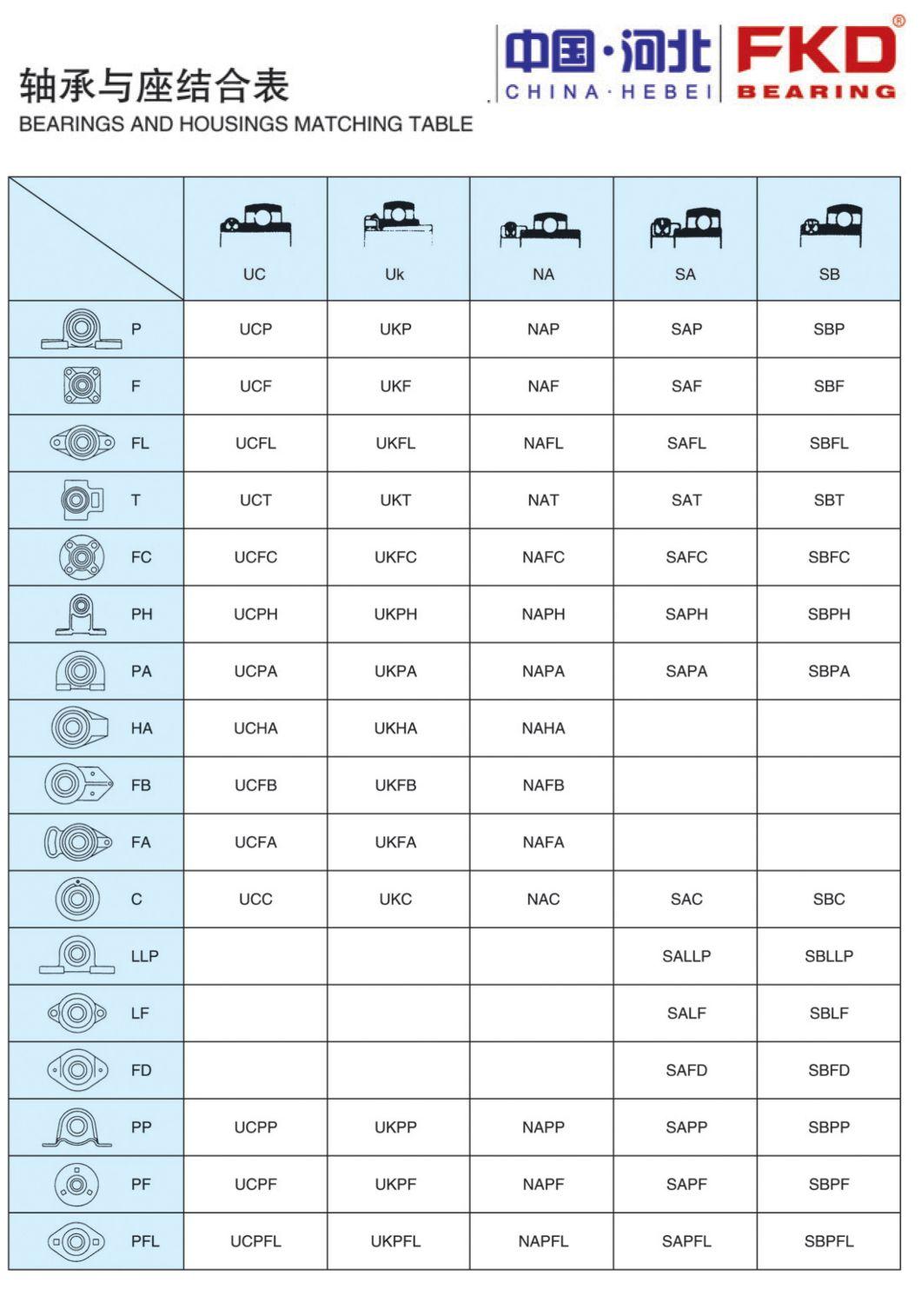

- Bearing Series:UC, UK, Uel, SA, Sb, Hc etc

- Series:UCP, Ucf, UCFL, Ucfc, Ucph, Ucpa etc

- Bearing Housings Series:P. F. FL. pH. PA. Fb. Fa. T. FC etc.

- Quality Certification:ISO9001: 2008, GB , T 19001-2008

- Transport Package:Plastic Bag+Individual Box +Master Carton+Pallet

- Specification:ABEC-1

- Trademark:FKD FE HHB

- Origin:Hebei China

- HS Code:8483200000

- Production Capacity:30000,Days

Description

Cast Iron Mounted Bearing Units

FKD Cast Iron Mounted Bearing Units are manufactured UNDER ISO9001 certified facilities.FKD Mounted Bearing Unit housings are made from high strength cast iron. The housings are designed with normal/solid base construction and reinforced bolt hole areas. FKD Mounted Bearing Unit product line is available in many different housing styles with various attachment methods and positions.

The insert bearings' inner ring, outer ring and balls are produced using vacuum degassed 52100 bearing steel. These components are heat treat hardened to produce a durable wear surface on the balls and ball tracks. FKD uses cold rolled steel for ball retainers and shields.

The insert bearing features a labyrinth sealing system that is comprised of a metal backed nit rile rubber excluder seal that is designed to keep grease in and contaminants out. The seal is protected by steel flinger installed in front of the seal contact surface with the inner ring. This flinger, due to centrifugal force during bearing rotation, effectively slings moisture and contaminants away from the seal area. The seal is designed to allow used grease to purge past the seal into the channel between the seal and the flinger when new lubricant is carefully replenished.

All FKD Mounted Bearing Units are factory lubricated using GREAT WALL grease with about 30-40% grease fill.

Relubrication

Lubrication

Insert bearings in FKD Cast Iron Mounted Bearing Units have sufficient high-grade grease installed after assembly. There is no need for replenishment during initial operation in new installations. FKD bearing units normal grease content is about one third to one half of the internal space inside the bearing.

Re-greasing

The performance of a bearing is greatly influenced by the quality and quantity of the grease. FKD recommends GREAT WALL/ SHELL grease. In order to avoid over filling, it is advisable to replenish the grease in small amounts. A hand grease gun should only require a few pumps per bearing for most sizes and conditions. Over lubrication is a major cause of bearing failure. Over filling can increase heat build-up in the bearing during operation which can lead to premature failure. Over filling can dislodge seals and flingers from their mounting position thereby interfering with the rotation of the bearing or destroying the integrity of the seal.

FKD bearings are lubricated with GREAT WALL from the factory. The grease used for replenishment should be checked for compatibility before application.

Lubrication Intervals

Bearing units are generally relubricatable from the factory. Depending on the operating conditions, relubrication on the bearings is not always necessary where environments are clean and temperatures are low. It is normal to see a small amount of grease at the edge of the flinger during and after operation. Grease deteriorates overtime and should be replenished. Lubrication intervals are a function of the environmental conditions coupled with the operating temperature. General lubrication intervals are shown in THE ACCOMPANYING CHART. There is no substitution for recommendations by the equipment manufacturer and/or observation by operators to determine the appropriate lubrication cycles.

Company Profile

Hebei Hailan Bearing Manufacture Co., Ltd( was originally founded in 1988 as Xingtai Honghai Bearing Manufacture Co., Ltd) is the most professional manufactuer of Pillow Block Bearings in the north of China.It is located in LinXi county, HeBei Province, China, the hometown of bearing.

The company mainly produces UC, HC, UK, SER, SA, SB, AGRI-BEARING and various of bearings, and all kinds of bearing housings P, F, FC, FL, T , CC, pH, PA, FA, FB, HA, LF,ect.

Advanced CNC, grinding and assembly equipment ensures the precision .

Professional testing laboratory strickly test and control the quality of raw materials and finished products.

FKD Bearings constantly promote the quality, expand the market.

Products have exported to North Amercia, South Amercia, Eastern Europe, Southeast Asia, Africa, Middle East, Eastern Asia, Western Europe more than 40 countries and regions.

FAQ

FAQ1. Is there a procedure to conduct random product inspection after final packaging in place?

Have clear stanards and written inspection records

2.Is there a clear procedure for handling customer complaints?

Has the clear procedure and followed records

3.Can the finished/ packaged product be traced by lot identification to the appropriate raw materials test report?

Can trace main materials

4.Are corrective & preventive actions mechanism established and implemented effectivly( including the suppliers / sub-contractors control, incoming inspection, process control, final inspection and customer complaint)?

Has the clear procedure and followed records

Ms. Spring

Sales Department

Hebei Hailan Bearing Manufacture Co., Ltd