22.5*7.5 The Popular Forged Steel Wheels Rims for 10r22.5

Xiamen (China) Businessway Environmental Protection Technology Co., Ltd.- After-sales Service:1 Year

- Warranty:1 Year

- Material:Steel

- Type:Rim

- Drive Wheel:8*4

- Wheel Hub Diameter:21-24"

Base Info

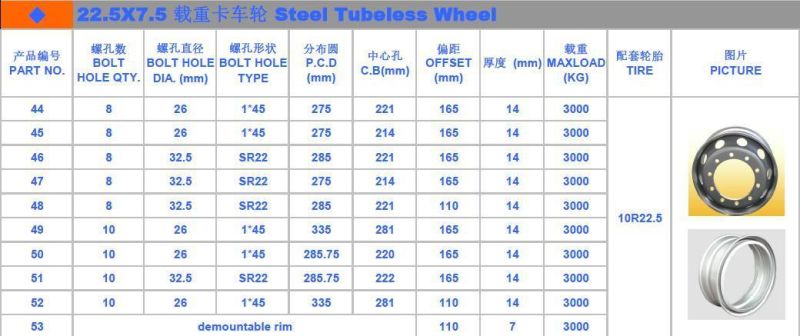

- Model NO.:22.5*7.5

- Finishing:Silver

- Wheel Accessories:Wheel Spoke

- Spoke Type:Flat Spoke

- Certification:ISO, VIA, CE, TUV, DOT

- Wheel Hub Brand:Joyoway

- Spray Painting Process:Electrophoretic Paint

- Weight:39.5kg

- Bolt Hole Qty.:8,10

- Bolt Hole Dia. (mm):26,32.5

- Bolt Hole Type:1*45,Sr22

- P.C.D (mm):275,285,285.75,335

- C.B(mm):214,220,221,222,281

- Offset (mm):165,110

- Disc Thickness(mm):14

- Rim Thickness(mm):6

- 20"Gp(PCS):320

- 40"Gp(PCS):640

- 40"Hq(PCS):720

- Valve:V3-20-4

- Max Load(Kg):3000

- Transport Package:Pallet or Double Packing

- Specification:1.15M*1.15M*1.3M

- Trademark:JOYOWHEEL

- Origin:Shandong China

- HS Code:8708705000

- Production Capacity:20000pieces,Mounth

Description

Basic Info.

Model NO. 22.5*7.5 Finishing Silver Wheel Accessories Wheel Spoke Spoke Type Flat Spoke Certification ISO, VIA, CE, TUV, DOT Wheel Hub Brand Joyoway Spray Painting Process Electrophoretic Paint Weight 39.5kg Bolt Hole Qty. 8/10 Bolt Hole Dia. (mm) 26/32.5 Bolt Hole Type 1*45/Sr22 P.C.D (mm) 275/285/285.75/335 C.B(mm) 214/220/221/222/281 Offset (mm) 165/110 Disc Thickness(mm) 14 Rim Thickness(mm) 6 20"Gp(PCS) 320 40"Gp(PCS) 640 40"Hq(PCS) 720 Valve V3-20-4 Max Load(Kg) 3000 Transport Package Pallet or Double Packing Specification 1.15M*1.15M*1.3M Trademark JOYOWHEEL Origin Shandong China HS Code 8708705000 Production Capacity 20000pieces/MounthProduct Description

Dongying JoYo Auto Parts Co., Ltd is a sales company of Shandong Yujie wheel group Co., Ltd. which was founded in 2004, it is a company specializing in the manufacturing and sales of light and heavy truck wheels. It is located in Guangrao Xishui Industrial Park, the first tire village in China, it is two and a half hours away from Qingdao port.

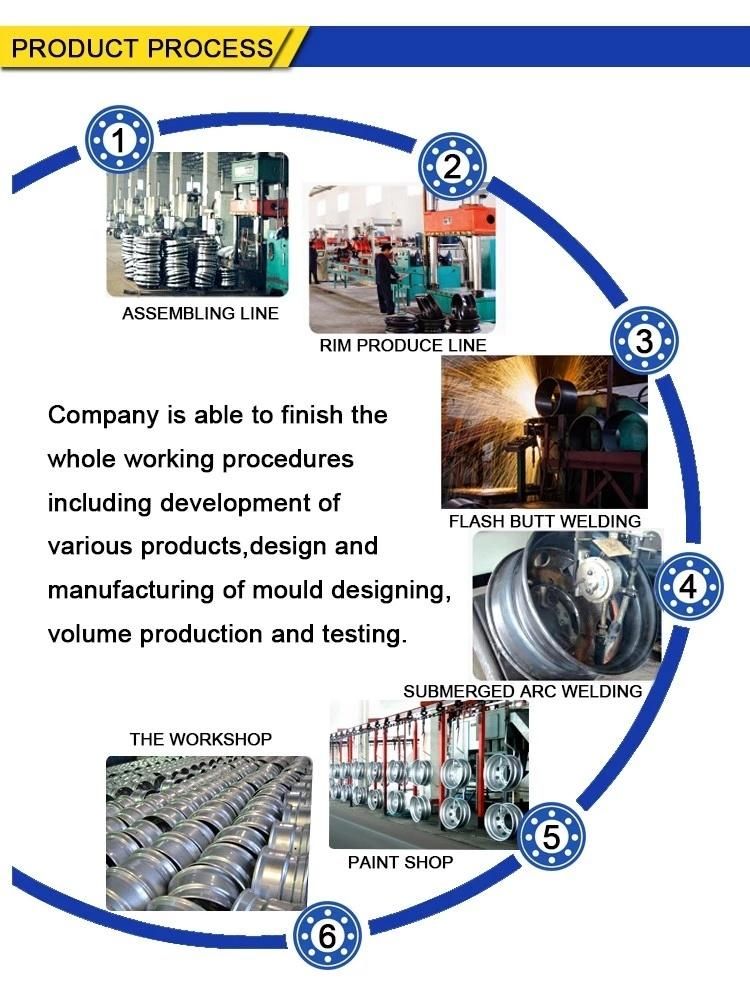

Dongying JoYo Auto Parts Co., Ltd is a sales company of Shandong Yujie wheel group Co., Ltd. which was founded in 2004, it is a company specializing in the manufacturing and sales of light and heavy truck wheels. It is located in Guangrao Xishui Industrial Park, the first tire village in China, it is two and a half hours away from Qingdao port.Now the company has 2 production lines of tube steel wheels, which can produce 16 inch 20 inch 24 inch wheels, 4 production lines tubeless steel wheels, 2 production lines of forged aluminum alloy wheels, which can produce 16 inch wheels, 17.5 inch wheels, 19.5 inch wheels, 22.5 inch wheels, 24.5 inch wheels with various specifications and thickness requirements.

We have been specializing in the production of wheels for 16 years. We have our own design and development team and product testing laboratory. We are one of the earliest and most complete wheel manufacturers in China.

The steel wheels are pulse welded so that no marks can be seen on the rim. Large cathode electrophoresis pickling phosphating coating production line, electrostatic spraying equipment, this makes our wheels appearance more beautiful, paint adhesion for longer, more corrosion resistance, more acid and alkali resistance.

Aluminum alloy wheel production line forging press is 12000 tons, spinning machine is the world's most advanced equipment which is produced by Switzerland LEIFIELD company. German MOSSNER bandsaw sawing machine makes the cutting of aluminum section more accurate. Integrated production line from Taiwan CHEVLIER, makes one aluminum wheel exactly in 4 minutes. And the use of ABB Robot makes the whole workshop only need 50 workers with 2000 pieces daily capacity .