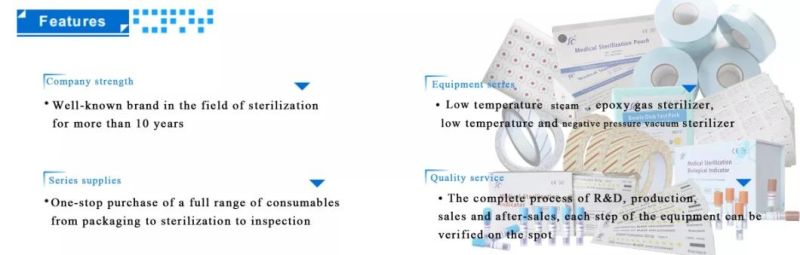

Sterilization Chemical Indicator Tape H2O2 Plasma Sterile Other Medical Consumables

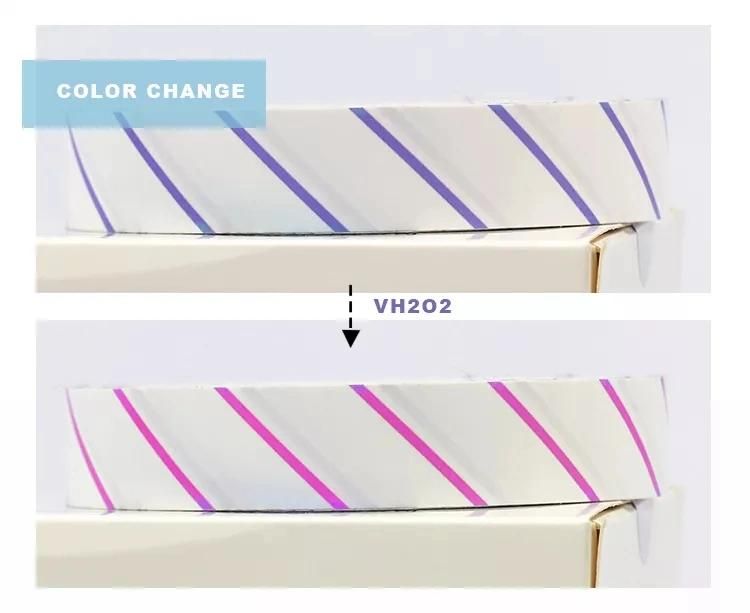

XIAMEN HONGJU UNITED TECHNOLOGY CO., LTD.- Type:Hydrogen Peroxide H2O2 Plasma Chemical Indicator T

- Material:Adhesive Tape + Chemical Indicator Color Bar, Adhesive Tape + Chemical Indicator Color Bar

- Ethylene Oxide Sterilization:Without Ethylene Oxide Sterilization

- Quality Guarantee Period:Two Years

- Group:Adult

- Logo Printing:With Logo Printing

Base Info

- Model NO.:T3201

- Instrument Classification:Class I

- Product Name:Plasma Indicator Card

- Safety Standard:["En 149 -2001+A1-2009","CE Certification; ISO14001,ISO9001,ISO45001"]

- Quality Certificate:CE

- Usage:Professional and Home

- Size:20mmx30m

- MOQ:50 Rolls

- Properties:Medical Materials & Accessories

- Properties Items:in-Package Test Card

- Width:20mm

- Length:30m

- Transport Package:200PCS, Bottle; 100 Bottle,Carton

- Specification:20mmx30m

- Trademark:SANQIANG

- Origin:China

- Production Capacity:30000000 Roll,Rolls Per Month

Description

55x24.4x12.2Intended Use: 1.Verify that the sterilization conditions are met during the sterilization pro cess. 2.Distinguish whether the items in the package have been exposed in sterilization substances. 3.Record the sterilization information.

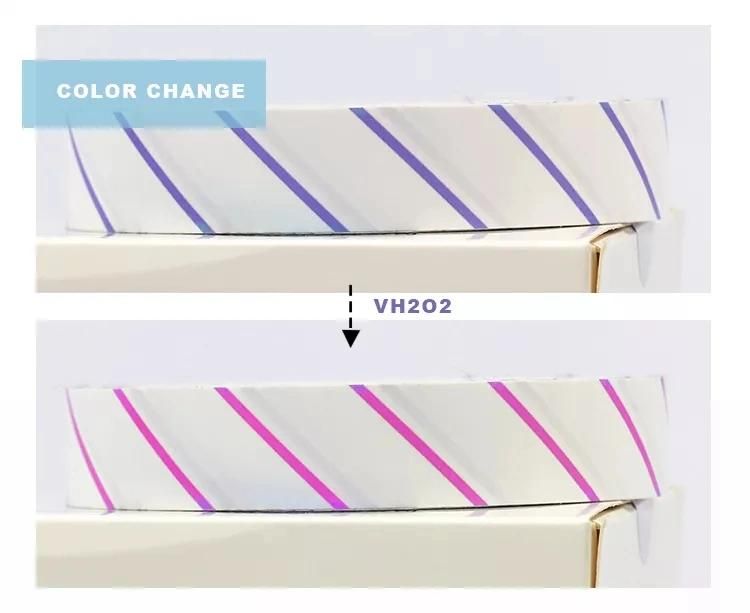

nstruction for Use: For the EO Indicator Tape, cut the appropriate length of it and stick it on the surface of the package to be sterilized. After the sterilization, observe the color change.

Package chemical monitoring for pressure steam sterilization, showing whether the package has been sterilized. The tape can be used for various packaging materials such as cotton fabric, non-woven fabric, paper and plastic packaging. Paste directly outside the package, you can directly observe the discoloration, determine whether the package has passed the sterilization process and preliminary assessment of the sterilization quality of the package.

Package chemical monitoring for pressure steam sterilization, showing whether the package has been sterilized. The tape can be used for various packaging materials such as cotton fabric, non-woven fabric, paper and plastic packaging. Paste directly outside the package, you can directly observe the discoloration, determine whether the package has passed the sterilization process and preliminary assessment of the sterilization quality of the package.

Sterilization method:

Sterilization method:

1. Record the necessary items for sterilization management in the blank space of the biological indicator label;

2. In each sterilization cycle, in accordance with the requirements determined by the sterilization process, put the required number of biological indicators in the designated position in the sterilizer;

3. After the sterilization process, take out the biological indicator, after cooling at room temperature, break the ampoule with a clip, shake the small plastic tube several times to ensure that the infection carrier is completely immersed in the culture solution;

4. Place the bottle in a vertical position at 36ºC±2ºC to incubate for 24 hours, and observe whether the culture solution changes from green to yellow after the end; Note: If the color changes from green to yellow, it means that the sterilization is unqualified. If the color is still green after 24H, it means that the sterilization is qualified;

nstruction for Use: For the EO Indicator Tape, cut the appropriate length of it and stick it on the surface of the package to be sterilized. After the sterilization, observe the color change.

Package chemical monitoring for pressure steam sterilization, showing whether the package has been sterilized. The tape can be used for various packaging materials such as cotton fabric, non-woven fabric, paper and plastic packaging. Paste directly outside the package, you can directly observe the discoloration, determine whether the package has passed the sterilization process and preliminary assessment of the sterilization quality of the package.

Package chemical monitoring for pressure steam sterilization, showing whether the package has been sterilized. The tape can be used for various packaging materials such as cotton fabric, non-woven fabric, paper and plastic packaging. Paste directly outside the package, you can directly observe the discoloration, determine whether the package has passed the sterilization process and preliminary assessment of the sterilization quality of the package.

Sterilization method:

Sterilization method:1. Record the necessary items for sterilization management in the blank space of the biological indicator label;

2. In each sterilization cycle, in accordance with the requirements determined by the sterilization process, put the required number of biological indicators in the designated position in the sterilizer;

3. After the sterilization process, take out the biological indicator, after cooling at room temperature, break the ampoule with a clip, shake the small plastic tube several times to ensure that the infection carrier is completely immersed in the culture solution;

4. Place the bottle in a vertical position at 36ºC±2ºC to incubate for 24 hours, and observe whether the culture solution changes from green to yellow after the end; Note: If the color changes from green to yellow, it means that the sterilization is unqualified. If the color is still green after 24H, it means that the sterilization is qualified;