Leonessa Double Row Ball Slewing Ring Bearing External Toothed Swing Bearing Geared Turntable Bearing (VE050B01 VE061B00 VE086B03 VE098B00 VE108B03)

Right Team Holding Ltd.- Standard or Nonstandard:Standard

- Feature:Cold-Resistant, Corrosion-Resistant, Heat-Resistant

- Sealing Gland:Sealed On Both Sides

- Rolling-Element Number:Double-Row

- Roller Type:Deep Groove Raceway

- Material:50mn or 42CrMo

Base Info

- Model NO.:VE050B01 VE061B00 VE086B03 VE098B00 VE108B03

- Type:External Gear

- Production Experience:Since Year 1993

- Customer Design:Available

- Inspection:Lyhy or 3rd Party

- Warranty Period:18 Months

- Production Time:30-45 Days

- Precision:P0, P6, P5

- Cage Material:Nylon, Aluminum, Brass, Steel

- Transportation:by Sea, by Air, by Railway, by Express

- Transport Package:Wooden Box

- Specification:ISO9001: 2008

- Trademark:LYHY

- Origin:China

- HS Code:848210900

- Production Capacity:1000PCS Per Month

Description

Basic Info.

Model NO. VE050B01 VE061B00 VE086B03 VE098B00 VE108B03 Type External Gear Production Experience Since Year 1993 Customer Design Available Inspection Lyhy or 3rd Party Warranty Period 18 Months Production Time 30-45 Days Precision P0, P6, P5 Cage Material Nylon, Aluminum, Brass, Steel Transportation by Sea, by Air, by Railway, by Express Transport Package Wooden Box Specification ISO9001: 2008 Trademark LYHY Origin China HS Code 848210900 Production Capacity 1000PCS Per MonthProduct Description

Please see details for slewing ring bearing swing bearing turntable bearing:Single row ball slewing bearing ring swing bearing

External toothed gear

VE030A00 VE031A01 VE040A01 VE043A05 VE045A00 VE050A02 VE050A10 VE059A00

VE059A10 VE059A22 VE064A00 VE064A07 VE079A00 VE084A01 VE086A00 VE097A00

VE114A05 VE120A01 VE120A05 VE140A01 VE180A00

Internal toothed gear

VI040A01 VI053A00 VI057A01 VI064A05 VI075A00 VI085A05 VI085A08 VI095A01 VI095A14

VI100A00 VI104A04 VI105A03 VI105A04 VI129A00 VI142A01 VI147A00 VI160A01 VI200A01

Untoothed ungearless

VS032A02 VS040A00 VS051A03 VS064A08 V5069A06

Double row ball slewing bearing ring swing bearing

External toothed gear

VE050B01 VE061B00 VE086B03 VE098B00 VE108B03 VE114B00 VE120B00 VE120B01

VE120B12 VE122B00 VE129B00 VE138B04 VE138B05 VE147B01 VE147B03 VE160B00

VE160B04 VE163B01

Internal toothed gear

VI057B02 VI085B00 VI095B01 VI097B06 VI098B03 VI101B00 VI107B01 VI117B01 VI117B06

VI120B00 VI120B01 VI125B01 VI134B00 VI147B01 VI147B02 VI153B03 VI153B06 VI175B03

Untoothed ungearless

VS050B00 VS061B00 VS098B00

Cross roller slewing bearing ring swing bearing

External toothed gear

V18E089 V25E139 V18E083 V25E013 V18E082 V25E195 V25E197 V30E081 V25E248

V25E131 V30E150 V25E062 V30E013 V25E250 V30E088 V30E123 V30E087 V30E151

V40E028 V40E027 V40E029

Internal toothed gear

V18I082 V18I089 V25I185 V25I001 V25I192 V25I161 V25I040 V30I132 V30I013

Untoothed ungearless

V18S077 V25S084 V18S080 V18S074 V25S085 V25S091 V30S018 V30S023

If you need more details, please feel free to contact us for designing and producing, Attn: Susan Yang

1. Why choose LYHY slewing bearings

Who we are?

We (Luoyang Huayang special heavy-duty and large bearing manufacturing CO., LTD) are a professional

bearing manufacturer in the world, established in 2000, specializing in slewing bearings, slewing drives

and special bearings, with design, production, sales, marketing and service from OD200mm to 8000mm.

For 18 years experiences, our bearings have flied to more than 50 countries.

Our technical team:

We have 60 employees, with 6 experienced engineers and professional technicists.

All our bearings are designed by CAD-programs, made according to customers' special demands.

Our technical team can also verify safety & reliability depending on the load case and the strength of raceway

as well as gear and bolt connections.

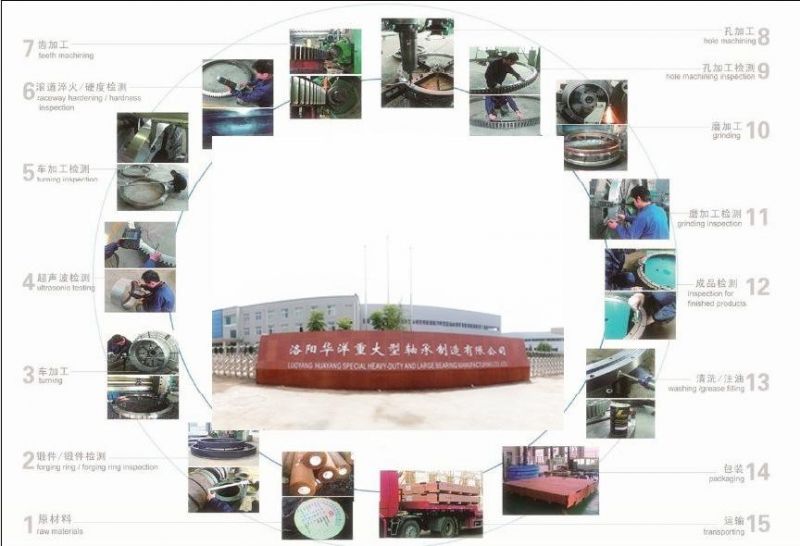

Manufacturing:

Equipped with advanced manufacturing equipments and test instruments, all bearings are of uniform marking

and packing with superior quality, reasonable prices and perfect services.

Quality:

We have been certificated by ISO9001:2008, and we are also aligned to international quality standards

from application consulting and engineering to productions, examinations, documentations and dispatch.

We will prepare additional test reports if customers need.

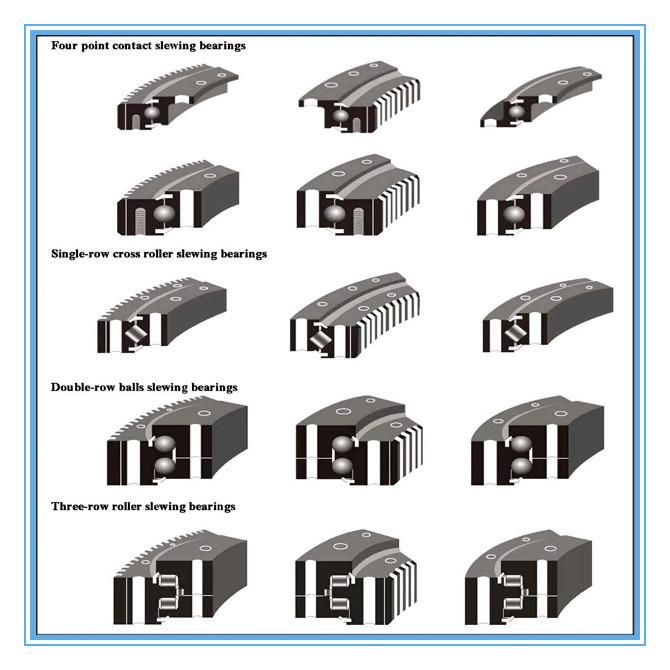

2. Structure of LYHY slewing bearings

Main Types:

Single row ball slewing ring bearings

Double row ball slewing ring bearings

Crossed roller slewing ring bearing

Three row cylindrical roller slewing bearings

BALL & ROLLER combined slewing bearings

Flanged slewing ring bearing

Gear Type:

Slewing bearings with external gear

Slewing bearings with internal gear

Slew bearings without gear

Flange type:

Slewing bearings with external flange and internal gear

Slew rings with internal flange and external gear

Slew bearings with external and internal flange

3. About LYHY bearings Advantages:

3.1 introduction:we are a manufacturer of slewing bearing since 1993, our factory occupies a area of 30000square meters with 4 workshop and 1 office building.

3.2 Featured products: slewing bearing and slewing drive

3.3 Capital: Current is 1 million RMB, but we are increasing the capital to 10 million RMB

3.4 Workers: 60

3.5 Certificate: ISO9001:2008, 3.1 certificate, CCS certificate

All LYHY slew rings can betested by the 3rd party inspection organization if customer requires, such as BV, CCS, SGS, LR, ABS and so on. All swing bearings inspection reports will be supplied to customers, including raw material certificate, heat treatment certificate, UT&PT and so on.

3.6 Annual Exportation: 8 million USD

3.7 Warranty Period: All LYHY slewing ring bearings have a warranty period of 18 months, for some special working condition, warranty period can be lengthened to 3-4 years.

3.8 Production Time: All LYHY slewing ring bearings can be usually delivered timely, usual production time is 15-50 days based on different slew bearings diameters, sometimes slew rings will be in stock.

3.9 Technical Control

All LYHY slewing ring bearings are forged rings with material steel 50Mn or 42CrMo, slewing rings are machined by CNC lathe, slew bearings raceway are quenched via medium-frequency hardening with hardness 55-60HRC, turntable bearings are drilled holes by CNC drilling machine, slew gears are machined by hobbing machine with gear quenched if required, swing bearings then are grinded by grinding machine with higher precision.

4. LYHY Slewing Bearing Packing

4.1 Basic Packing

Bearing surface is covered with the anti-rust oil first; and then wrapped with the plastic film;

And then packed with kraft paper and professional belts;

At last, with wooden box totally at the outer packing to invoid the rust or the moist;

We can depend on the customers demand to be packed;

4.2 LYHY slewing ring bearings can be packed by different ways.

If bearing diameter is less than 2300mm, slewing rings will be usually packed by square plywood case.

If bearing diameter is more than 2300mm, slewing rings can be packed by square plywood case, round plywood case, or steel tripod. Every package way can be totally kept goods safely.

5. LYHY Slewing Bearing Transportation:

Slewing bearings can be offered different delivery terms, such as EXW, FOB, CIF, DDU and so on.

Also, slewing rings can be transported by different transport ways, by express (such as DHL, TNT, UPS, FEDEX and so on), by air, by sea, by truck, by railway and so on.