Professional Electrostatic Powder Coating Reciprocator for Powder Coating Gun

Coolpack Canton Industrial Limited- After-sales Service:Online

- Warranty:12 Months

- Type:Painting Robots or Reciprocator

- Certification:CE

- Substrate:Steel

- Brand:Hicolo

Base Info

- Model NO.:COLO-2200D

- Coating:Powder Coating

- Voltage:110V,220V

- Morning:1.5 M, 1.8m, 2m, 2.5m

- Weight:300kgs

- Pacakge Size:3100X800X820mm

- Delivery Time:5 Days

- Transport Package:Wooden Carton

- Specification:3100x800x820mm

- Trademark:HICOLO

- Origin:China

- HS Code:8424899990

- Production Capacity:30 Per Month

Description

Basic Info.

Model NO. COLO-2200D Coating Powder Coating Voltage 110V/220V Morning 1.5 M, 1.8m, 2m, 2.5m Weight 300kgs Pacakge Size 3100X800X820mm Delivery Time 5 Days Transport Package Wooden Carton Specification 3100x800x820mm Trademark HICOLO Origin China HS Code 8424899990 Production Capacity 30 Per MonthProduct Description

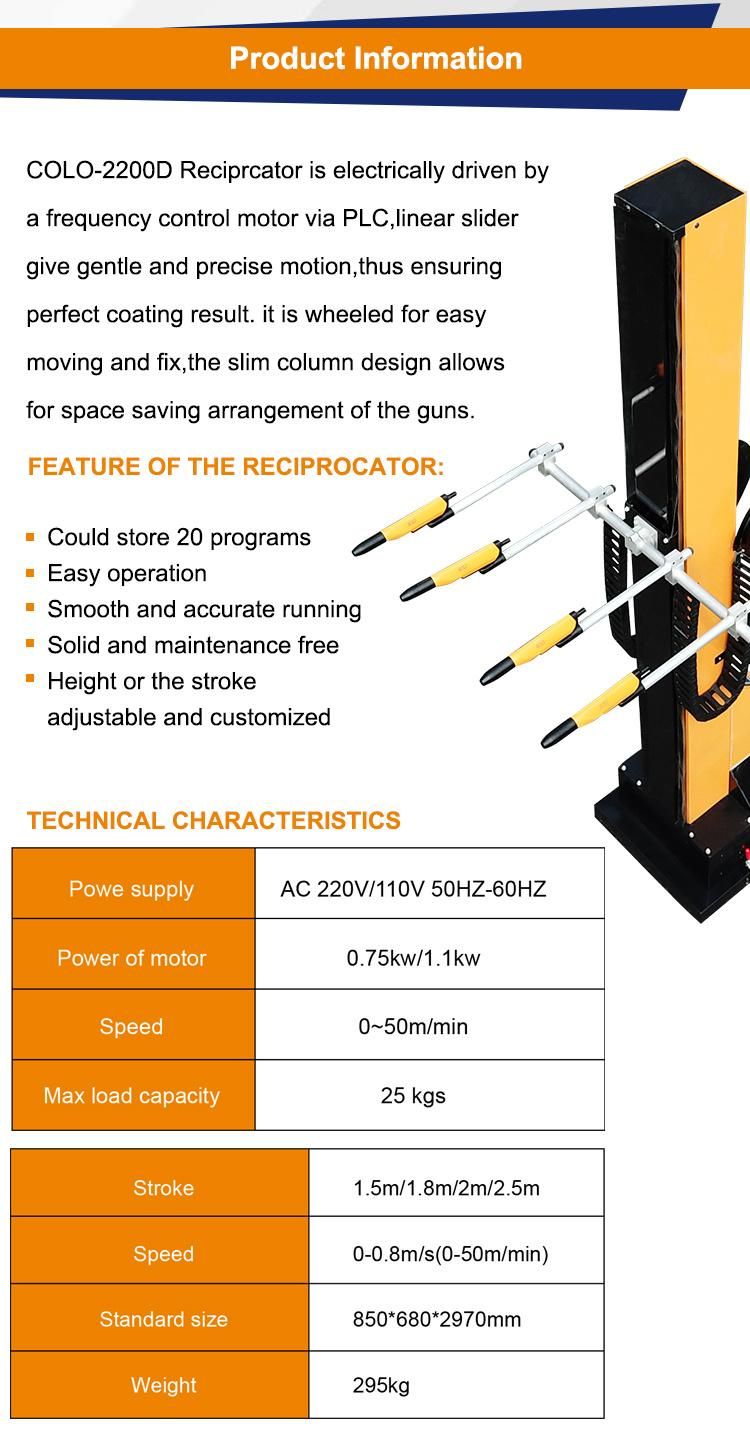

Professional Electrostatic Powder Coating Reciprocator for Powder Coating Gun

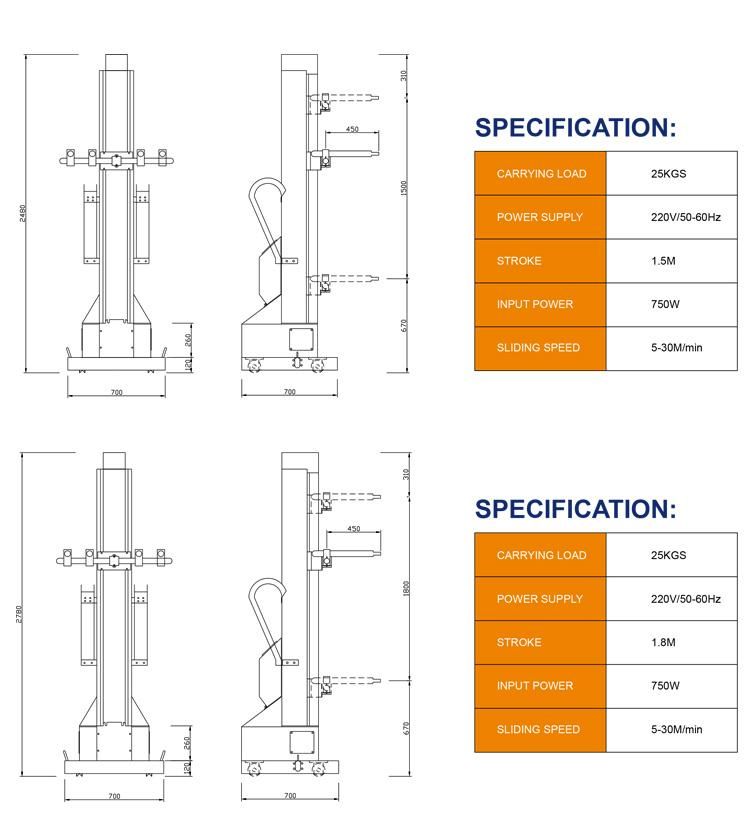

Professional Electrostatic Powder Coating Reciprocator for Powder Coating GunThis is important part of a automatic powder coating line. Automatic Reciprocator (reciprocating machine) (Work with Electrostatic Powder Coating Gun) With several electrostatic powder coating gun on the reciprocator Japan Mitsubishi Transducer & PLC controlled Four automatic spray gun rods(qty of the rods can be ordered) .

Technical characteristics Reciprocator of Powder Coating Line

| Power supply | AC220V 50-60hz |

| Frequency | Japanese Mitsubishi |

| Power motor | 0.75KW |

| Sweep speed | 0~60m/min speed adjustable by inverter. |

| Acceleration | 1M/Second |

| Low limit setting by potentiometer | |

| Environmental | 0~50degree |

| Star signal model: | digital display |

| Max load capacity | 40 |

| Motion Range | 0.3~2.5M(Can be setting) |

The benefits of colo-2200D Reciprocator of Powder Coating Line are:

80 storable programs

Maintenance-free motor

Extremely smooth running through chain

High loading capacity and stability

Long-stroke and short -stroke operation

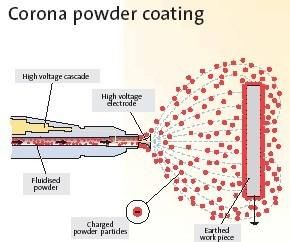

The powder coating application is done using an electrostatic spray gun. Electrostatic guns work because the powder is electrically charged utilizing compressed air and voltage. The powder is held in the hopper and fluidized. Once the trigger is pulled on the spray gun, the powder is pulled to and out of the gun using compressed air. In addition a voltage source creates an electrostatic field at the tip of the gun which imparts the powder with a positive charge. As a result, the powder adheres to the grounded part until heated in our convection oven, which initiates the curing process. Once coated, the parts are sent into our convection oven.

More pictures about our company.