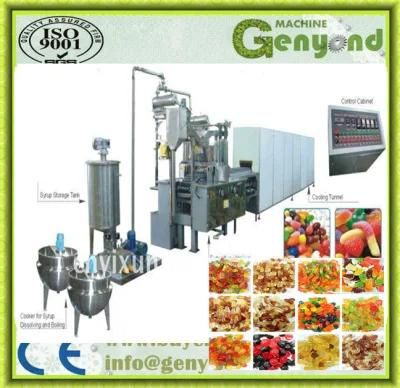

Hot Sale Automatic Jelly Candy Depositing Machine

Jiangyin Yiran International Trading Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Forming

- Automatic Grade:Automatic

- Application:Candy, Chocolate, Biscuit

- Customized:Customized

Base Info

- Model NO.:GYJC-200

- Material:Stainless Steel

- Turn-Key Project:Yes

- Capacity:30-600kg Per Hour

- Brand:Genyond

- Transport Package:Standard Export Package

- Specification:CE&ISO9001

- Trademark:GY

- Origin:Shanghai China

- HS Code:8438200000

- Production Capacity:800 Sets Per Year

Description

Superiority:

1.You can adjust the System program,when the machine is working.

2.PLC control system.

3.Health products, very few defective.

4.Candy shape can be flat and three-dimensional.

5.If using refrigeration equipment, it can't be affected by temperature and the surrounding environment.

6.Keeping the candy vitamins, it can overcome the character that carrageenan hasn't acid resistance .

7.Automatic demoulding.

8.Depositer has heat preservation system.

9.cooling type:according to the demands of customer. refrigerating machine or circulating fan

10.moulds is free.we can provide any shape mould according to your demands.

11.SE-II can produce carrageenan/pectin/ mixed glue jely candy,and ect..

PLC/computer process control available;

An LED touch panel for easy operating;

The standard production capacity is from 150kg/h to 600kg/h;

The main part is made of hygienic stainless steel;

Optional(mass)flowing controlled by Frequency inverters;

In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid;

Dosing pumps for the automatic injection of colors ,flavors and acids;

AUTOMATIC STEAM CONTROL SYSTEM instead of manual steam value which controls a stable steam pressure supply to the micro-film cooker;

"two-color stripe depositing","two-color double layers depositing","central filling","clear","butterscotch" hard candy can be made;

Moulds can be made according to the candy samples provided by customer;