20%-80%CaCO3 Filler Masterbatch Air-Cooling Pelletizing Machine

ShunDe Jiatian Hard Tool Co., Ltd.Base Info

Description

Extruder Machine Information in this air cooling hot cutting lineModel TSE-75 Screw diameter 71mm Main drive motor : AC 132kw, speed regulated by ABB transducer Screw rotary speed 400-600 rpm Screw material 38CrMoAl Production capacity 500kg/h

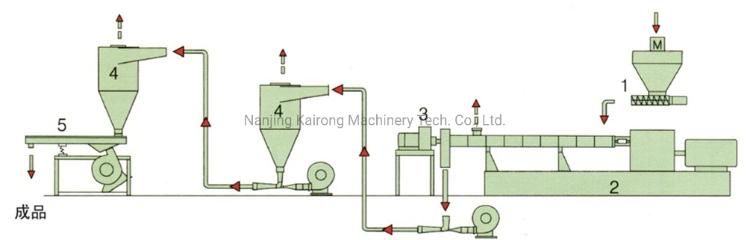

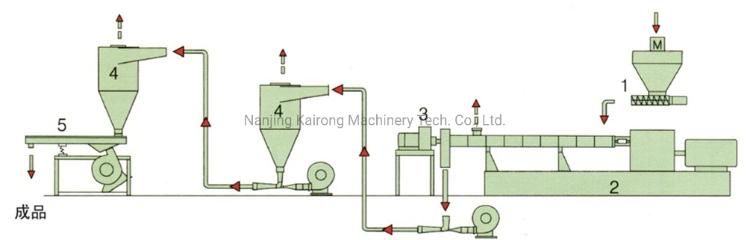

Air cooling hot cutting line for two stage extruder

It can also equipped with two stage extruder, which combine the high speed and extensive mixing of processing and the low speed, low temperature, and low shear of single screw processing; Ideal for compounding of heat-and shear-sensitive material, such as PVC compounds for cable, shoe sole, transparent container, and medical applications EVA shield cable compounds, carbon black masterbatch of PE, EVA, etc.

1.Metering Feeder 2.Veritical Forcing Feeder 3.Twin Screw Extruder 4.Single Screw Extruder 5.Air Cooling Pelletizer 6.Cyclone 7. Bioling Bed

Two stage air cooling hot cutting line test running

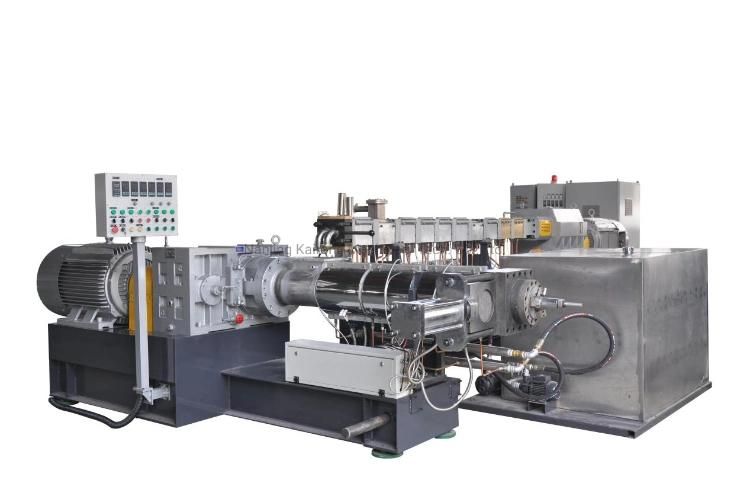

Extruder Machine Information in this air cooling hot cutting line

Extruder Machine Information in this air cooling hot cutting lineModel SP-75/180 Screw diameter 71/180mm Main drive motor 132/90kw Screw rotary speed 600/90 rpm L/D 32-64/8 Production capacity 600kg/h Features First stage twin screw extruder provides mixing and dispersion without over-shear.

Second stage lower speed single screw extruder provides enough cooling and pressure accumulation.

Nanjing Haisi Extrusion is well experienced in twin screw extruder manufacturing, with CE, TUV product quality certification. If you are interest in air cooling hot cutting line, please feel free to contact us.

Air cooling hot cutting line for two stage extruder

It can also equipped with two stage extruder, which combine the high speed and extensive mixing of processing and the low speed, low temperature, and low shear of single screw processing; Ideal for compounding of heat-and shear-sensitive material, such as PVC compounds for cable, shoe sole, transparent container, and medical applications EVA shield cable compounds, carbon black masterbatch of PE, EVA, etc.

1.Metering Feeder 2.Veritical Forcing Feeder 3.Twin Screw Extruder 4.Single Screw Extruder 5.Air Cooling Pelletizer 6.Cyclone 7. Bioling Bed

Two stage air cooling hot cutting line test running

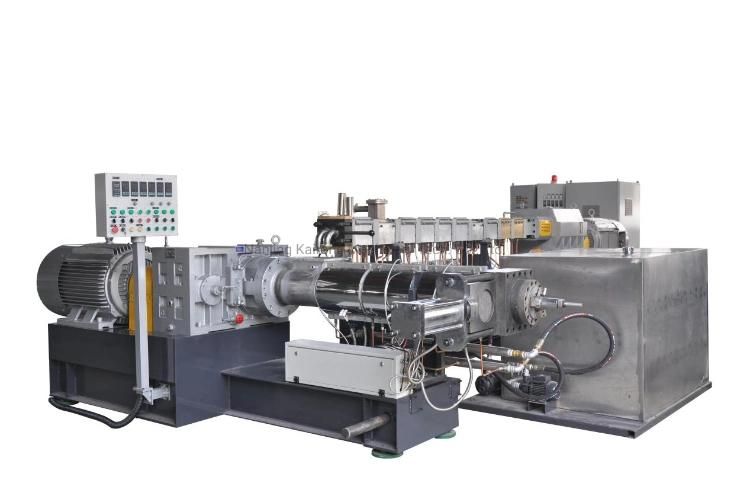

Extruder Machine Information in this air cooling hot cutting line

Extruder Machine Information in this air cooling hot cutting lineSecond stage lower speed single screw extruder provides enough cooling and pressure accumulation.

Nanjing Haisi Extrusion is well experienced in twin screw extruder manufacturing, with CE, TUV product quality certification. If you are interest in air cooling hot cutting line, please feel free to contact us.