Semi Automatic Fresh Potato Chips and Cassava Chips Processing Line

Wuxi Xinrun Protective Film Co., Ltd.- Certification:CE

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Chips, Crisp

- Customized:Customized

Base Info

- Material:304 Stainless Steel or According to Customer Requi

- Power:Depends

- Heating Method:Electric Heating

- Time:About 5min

- Transport Package:According to Customer Requirement

- Specification:depends

- Trademark:TIANSHUN

- Origin:China

- HS Code:8438600000

- Production Capacity:2000pieces,Year

Description

Basic Info.

Material 304 Stainless Steel or According to Customer Requi Power Depends Heating Method Electric Heating Time About 5min Transport Package According to Customer Requirement Specification depends Trademark TIANSHUN Origin China HS Code 8438600000 Production Capacity 2000pieces/YearProduct Description

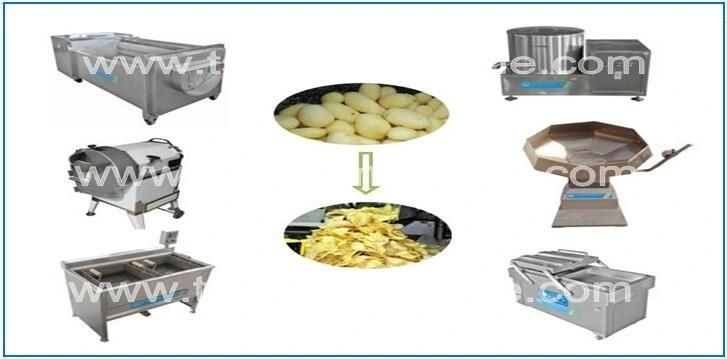

1.-Semi Automatic Fresh Potato Chips and Cassava Chips Processing LineThe Potato chips Production Line is composed of potato peeling & washing machine, potato chip cutting machine, potato chips blanching machine, dewatering or deoiling machine, seasoning machine and packing machineect.

Each machine of the potato chips making line is made of stainless steel, safe and easy to clean.

The whole chips line uses fresh potatoes as the raw material. It can produce crisp and high quality potato chips. We also design these Semi-Automatic Potato Chips Making Machine according to your capacity.

2.-Application of French fries making machine:

Widely be used for fresh potatoes, also can be used for other root vegetables, such as sweet potatoes, purple sweet potato, taro, cassava, and also the banana, plantain etc.

3.-Machines of Potato chips making line:

1)Washing and peeling machine: Potato skin removing

2). Potato cutter: This machine is used to cut potato into sticks, french fries quality depends on fries length and shape, so cutting machine is very important.

3). Blanching machine: Uused to deactivate the activity of the oxidase, take off the starch, separate out the reducing sugar, also after blanching,it will get inner soft taste of french fries.

4). Fryer: Auto temperature control, can set from 0-300degree

5). De-water machine: Used to remove water.

6). Seasonging machine: Made of SS 304 or according to customer demanding.

4.-Fully auto potato chips processing line:

Continuous fully automatic production line for potato chips, banana chips, tofu products and peanuts etc.