Three Vessels Brewhouse for Large Brewery Beer Kettle

Shenzhen Shiner Packaging Co., Ltd.- Condition:New

- Customized:Customized

- Voltage:380V

- Composition:SS304

- Processing Material:Beer

- Process:Boiling

Base Info

- Model NO.:2500L

- Material:SS304

- Tank Thickness:Inner 3mm Outside :2mm

- Temperature Control:Automatic

- Heating:Gas Steam Generator

- Heat Insulation:Rock Wool Th:80-100mm

- Inner Surface:Pickled and Passivation

- Welding:Argon Arc TIG 100%

- Function:Boiling Wort

- Transport Package:Steel Frame or Wooden Case

- Specification:as customer request

- Trademark:Zunhuang

- Origin:China

- Production Capacity:500piece

Description

Electric/Steam/direct fireArea Request >25M2 >30M2 >45M2 >50M2 >60M2 >70M2 Brewmaster 1 1 1 1 1 1

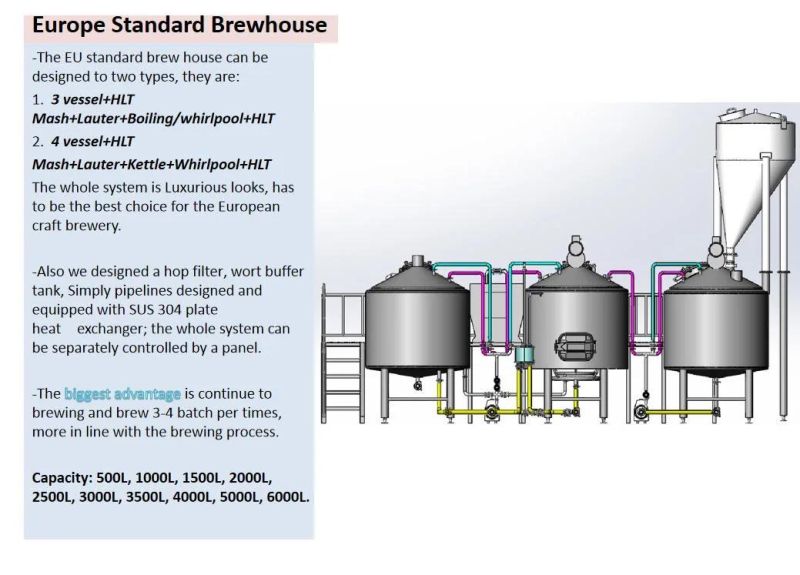

brewhouse: mash & lauter, boiling kettle$whirlpool. with hot liquid tank Electric steam boiler

Gas steam generator:

Inner surface pickled and passivation:

Mash &Lauter tun inside:

Fermentation system:

1. Capacity:500L OR 1000l working volume +25% Head space

2. Interior shell thickness 3-6mm, Exterior shell=2mm

3. 100% TIG welding with pure argon gas shield

4. Interior finish: pickled and passivated, external polished, 80mm insulated

5. Test pressure 3 bar, working pressure 1.5 bar

6. Glycol zones (Both on side and concial/bottom)

7. 60°conical bottom for Fermener, Shadow less side man way

8. Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

9. Mechanical relief valve 3 bar on CIP arm with pressure gauge

10.Adjustable tank leveling pads.

Auxiliary equipment:

brewhouse: mash & lauter, boiling kettle$whirlpool. with hot liquid tank Electric steam boiler

Gas steam generator:

Inner surface pickled and passivation:

Mash &Lauter tun inside:

Fermentation system:

1. Capacity:500L OR 1000l working volume +25% Head space

2. Interior shell thickness 3-6mm, Exterior shell=2mm

3. 100% TIG welding with pure argon gas shield

4. Interior finish: pickled and passivated, external polished, 80mm insulated

5. Test pressure 3 bar, working pressure 1.5 bar

6. Glycol zones (Both on side and concial/bottom)

7. 60°conical bottom for Fermener, Shadow less side man way

8. Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

9. Mechanical relief valve 3 bar on CIP arm with pressure gauge

10.Adjustable tank leveling pads.

Auxiliary equipment: