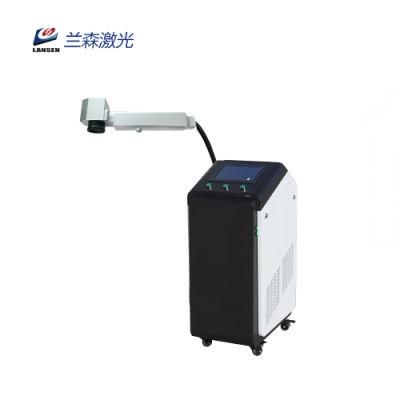

Handheld Structure Laser Scanner Dust Rust Laser Cleaning Machine

Taizhou Huangyan Lipeng Machinery Mould Factory- After-sales Service:Free Spare Parts

- Power:200w

- Control Type:Handheld

- Warranty:2 Years

- Model:LC-M1

- Laser Power:50W 100W

Base Info

- Model NO.:LS100W

- Transport Package:Plywood Box

- Specification:630mmX590mmX290mm

- Trademark:Lansen

- Origin:Jinan China

- HS Code:8456110090

- Production Capacity:300 Sets,Month

Description

Basic Info.

Model NO. LS100W Transport Package Plywood Box Specification 630mmX590mmX290mm Trademark Lansen Origin Jinan China HS Code 8456110090 Production Capacity 300 Sets/MonthProduct Description

Handheld structure Laser Scanner Dust Rust Laser Cleaning machine

Laser cleaning, on the other hand, is non-contact and non-abrasive, and so will only irradiate the material that you want to get rid of. This makes the process in particular, ideal for cleaning intricate and textured materials. You also have a great deal of control over the beam, meaning you can achieve the desired depth that you want to. Further to this, you can irradiate the whole surface layer of a material, or a much thinner layer, say the topcoat of paint, but not the primer below. Or, should you wish, you can just clean a very small section. If using another process which simply blasts the material, it is hard to enjoy such a high level of control. One of the key benefits in the way that laser cleaning works is that not much waste is left over due to the irradiation process; the substrate is simply vaporised rather than left as waste. The majority of the waste that is left over comes as dust particles and can be easily collected and removed by the user.

It is mostly dust particles that are left behind from the laser cleaning process As if all the above isn't

enough, the laser cleaning process is also much faster, leaving staff more able to complete other work and

not spend all of their time cleaning!

Application industry and purpose of Laser Cleaning Machine

Cleaning machine application industry microelectronics: semiconductor components, microelectronics, memory templates, etc.; cultural relic protection: stone carving, bronze, glass, oil painting and murals, etc.; abrasive cleaning: rubber molds, composite molds, metal molds, etc.; surface Treatment: Hydrophilic treatment, treatment of welds before and after welding, etc.; Paint removal and rust removal: aircraft, ships, weaponry, bridges, metal pressure vessels, metal pipes, etc.; aircraft parts, electrical product parts, etc.; Others: urban graffiti, printing rollers, building exterior walls, nuclear industry, Shipbuilding industry, auto parts, rubber molds, high-end machine tools, tire molds Track Environmental protection industry Weapon equipment industry Nuclear power industry and others etc,.

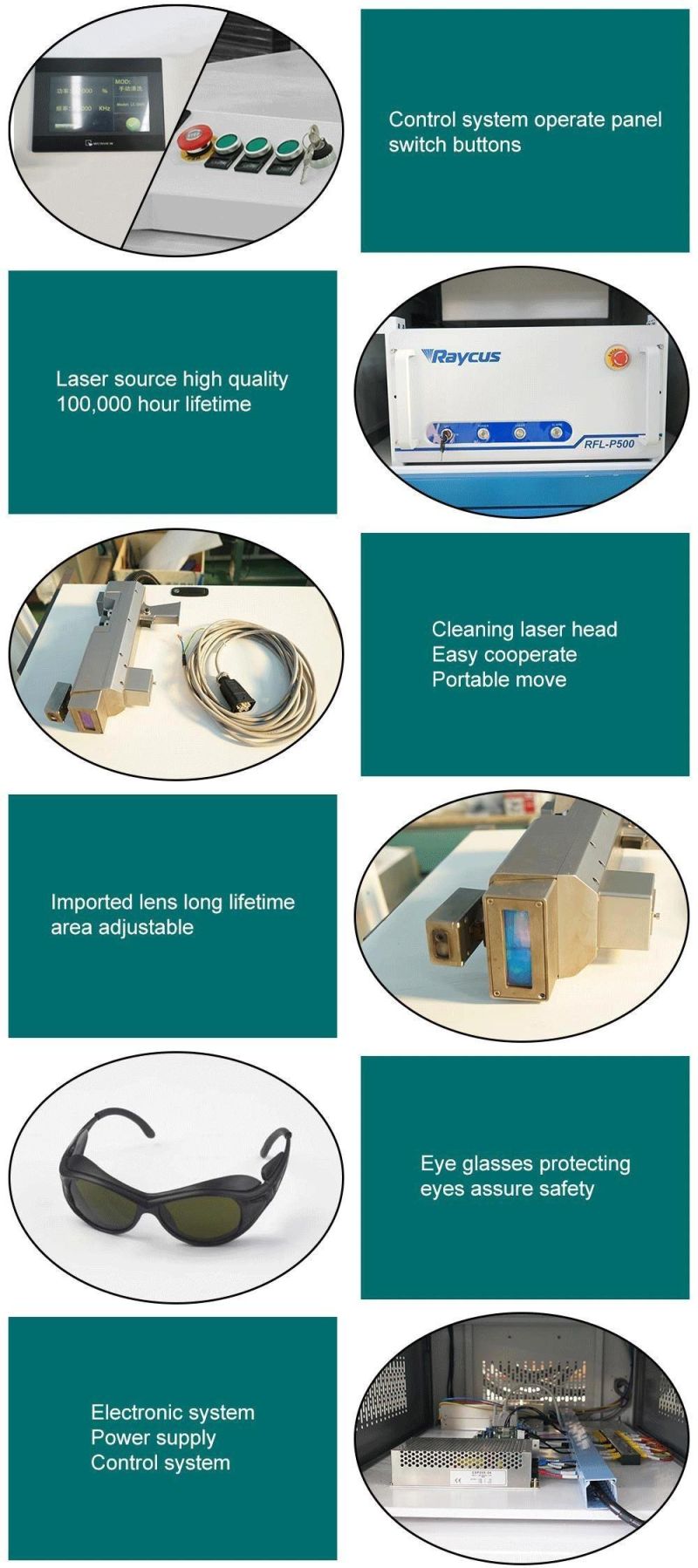

Parameters:

Model | LSF-50/ LSF-100 |

Laser Power | 50W/ 100W |

Scan head brand | Sino-Galvo |

Cooling way | Air cooling |

Laser Wavelength | 1064nm |

Laser Power | 0-100% |

Laser Frequency | 20-200KHZ |

Clean width | 1-20mm |

Clean length | 1mm,3mm,6mm,12mm,25mm,50mm,100mm |

Clean speed | 1-1000mm/s (adjustable) |

Working temprature | 0- 40 ºC |

Voltage | 220V±10%, 50-60hz |

LCD control panel size | 3.5inch |

Operation way | Handhold model |

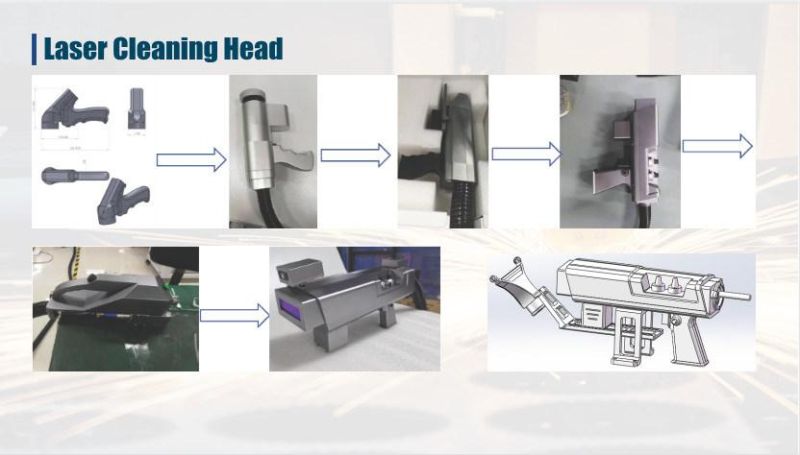

Hand-piece size | 406.5×70×113.7mm |

Hand-piece weight | 2.5±0.1Kg |

Optic cable length (bending radius≥250mm) | 3m, can be customized |

Working Humidity Conditions: | ≤ 80%RH |

Packing size | 630mmX590mmX290mm |

Machine size/Gross weight | 25kg/35.1kg |

Application range

* Surface oil, stains, dirt cleaning

* Metal surface rust removal

* Rubber mold residue cleaning

* Welding surface / spray surface pretreatment

* Surface coating, coating removal

* Surface paint removal, paint stripping treatment

* Stone surface dust and attachment removal

Features

* No damage to parts

* High efficiency, saving time

* Quick setup

* Simple interface operation

* Hand-held design is easy to carry

* No chemical required, safe and environmentally friendly

* No additional consumables are generated during cleaning

Product Details:

Introduction

* Powerful, very short, rapid and moving laser pulses produce micro-plasma bursts, shock waves and thermal pressure resulting in sublimation and ejection of the target material.

* A focused laser beam precisely vaporizes the target coating or contaminant.

* Process optimization of the laser beam produces maximum reaction with the target material for speed while, at the same time,does so safely and without harm to the base material.

* Metal surfaces are well-suited for many laser cleaning applications. Optimized beam settings will not metallurgical change or damage the laser treated surface. Only the coating, residue or oxide

targeted for removal is affected as the laser beam is precisely adjusted not to react with the underlying metal surface.

* Laser beam power density is accurately and easily adjusted to achieve cleaning results impossible with all other options.

Packing&Delivery

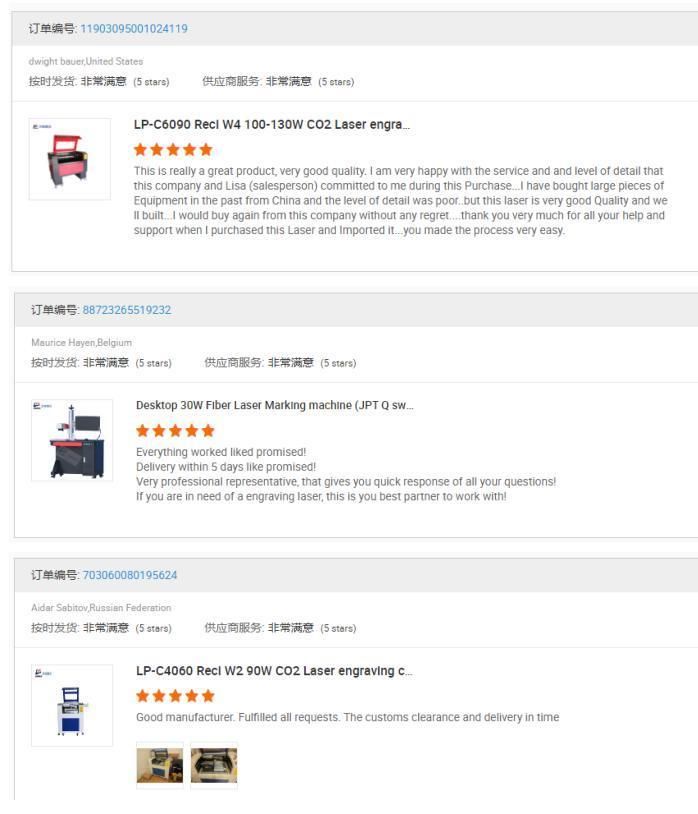

Feedbacks

After-Sale service

After-Sale service1. Every machine has 12 Months warranty.

2. In the warranty time machine has non-human damage, we can supply freely.Beyond warranty time, all will be cost price for change.

3. Detailed manual and video to guide the user how to use the machine and maintenance, also supply the specs settings for the speed and power to engrave or cut on various material.

4. Before machine delivery, we will test all the machines for 48 hours to guarantee their stability and has a strong package to guarantee their safety.

5.We supply free lifetime technical support and promise all questions will be answered within 2 hours.

FAQ

Q: How can I choose suitable machine?

A: Please communicate with us via inquiry or email, we can guide you. Please kindly tell us:

1) .What work table size you will need?

2).What work you will do?

Q: What's your payment terms? Delivery time and MOQ?

A: We accpet T/T(bank transfer), L/C, Paypal, Western union etc. Usually we need 30% as deposit, balance paid before shipment.

Delivery Time: 3-5 days after payment

MOQ: 1set

Q: If I bought a machine, how could you make it safe while shipping.

A: We have a professtional package suitable for oversea transpotation. Machine will be fixed well in the case.

Q: What's your quality control system?

A: All machines will be tested after finished. We have QC department response for this job. And we already got CE approved.

Q: If I don't know how to use the machine, can you teach me?

A: 1) There is a DVD disc including machine user manual and software user manual c/w machine.

2) Online (skype & phone)

3) Remote desktop software (Teamviewer)

4) Demo Video