PP PE ABS Plastic Single Shaft Shredding Machine Shredder

Shanghai Hampool Enterprise Co., Ltd.Base Info

Description

Basic Info.

Model NO. SR600-SR2500 Automation Automatic Computerized Computerized Certification CE, ISO9001:2008, SGS/BV External Dimensions(mm) 1700*2500*2000mm Transport Package According to Customer Specification CE/ISO9001/SGS Trademark SOYU Origin China HS Code 84778000 Production Capacity 1000sets/YearProduct Description

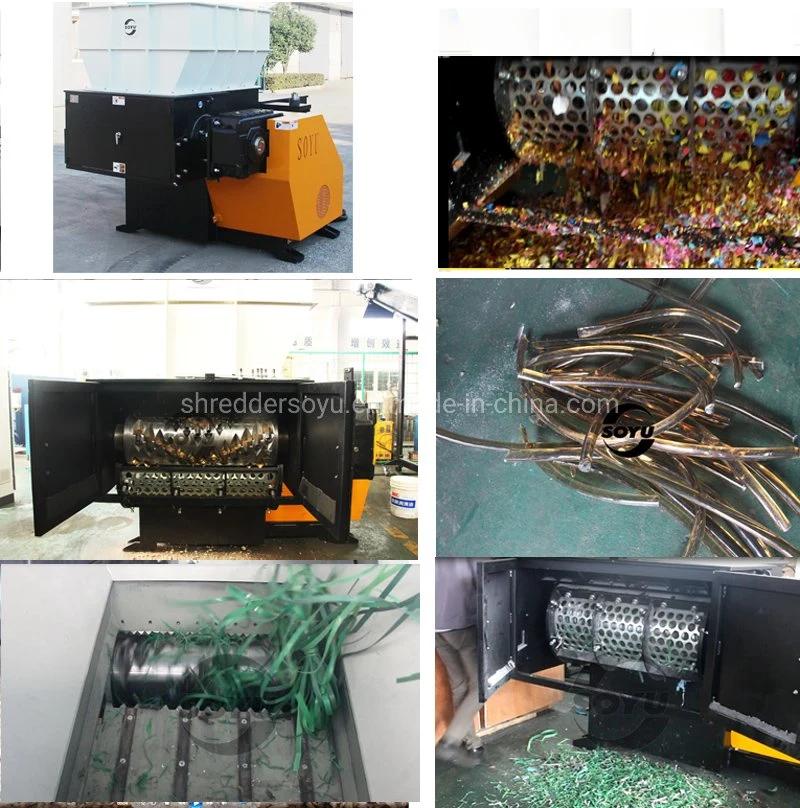

PP PE ABS Plastic Single Shaft Shredding Machine ShredderThis type of single shaft shredder is the conventional single shaft shredder, applicable to shred solid materials like plastic, rubber, fiber, paper, wood, electrical components and cable which are difficult to shred. For example, the sideline plastics, toe gum, hardboard, electronic board, wood, plastic barrel etc. Clients could select the corresponding model according to the material size and quantity. But the clear situation should be stated to us specially for shredding the ultra hard plastic such as nylon, ABS and PC.

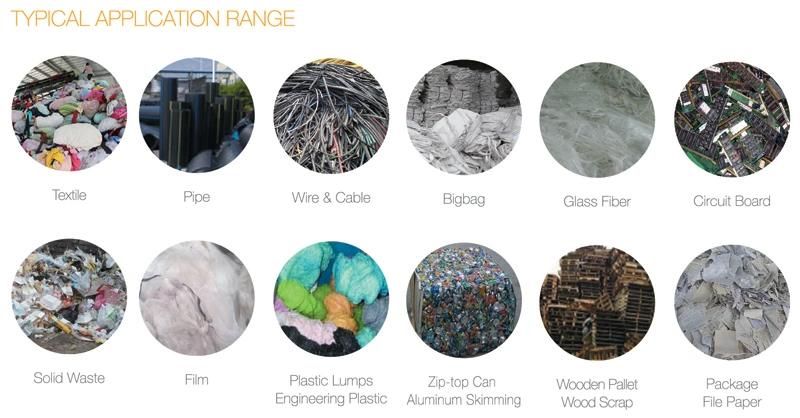

Suitable Shredding Applications:

- plastic lump and plastic block, like PP, PE, PET, PC, ABS, Nylon.

-Plastic pipes

-Film,Woven bags

- Living garbage,

- Medical waste

-Electronic Waste

-Copper Cable,Aluminum Cable with steel

- Aluminum cans

-Wood: Pallet,tree root,solid wood etc

fiber/film

paper/ hardboard

cable

wood

electrical board

pipe

toe gum

plastic barrel

Features:

• Teeth are DC53 steel. Stator knives are D2 steel.

• The main electronic controls are a combination of Siemens and Schneider.

• Microcomputer technology incorporating rotator speed variations with start, stop and reverse features.

• Automatic reverse sensors to protect the machine against over loading and jamming.

• Engineered using split bearing block technology so the blades can be changed quickly and efficiently.

• Specifically designed rotor to be extremely wear resistant.

• Rotor teeth can be rotated 4 times before they need changing, lowering running costs and reducing down time.

• Extremely versatile machine able to process a number of different materials

• Machinery protection, accord with the European CE standard.

| Model | SR600 | SR750 | SR900 | SR1100 |

| Main shaft speed(rpm) | 73 | 73 | 73 | 73 |

| Ram travel(mm) | 500 | 820 | 820 | 820 |

| Rotor diameter(mm) | Φ220 | Φ400 | Φ400 | Φ400 |

| Number of rotor blades(pcs) | 23 | 44 | 52 | 66 |

| Number of fixed blades(pcs) | 4 | 6 | 6 | 8 |

| Discharge height(mm) | 500 | 610 | 610 | 610 |

| Screen holes diameter(mm) | 40 | 40 | 40 | 40 |

| Motor power(kw) | 18.5 | 37 | 45 | 55~75 |

| Hydraulic power(kw) | 1.5 | 2.2 | 2.2 | 5.5 |

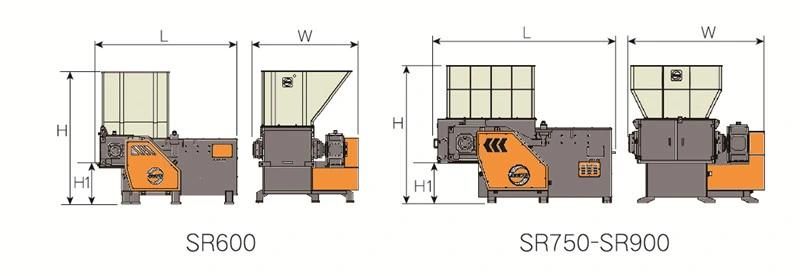

| Cutting chamber dimensions(mm) | 540x600 | 830x708 | 830x840 | 830x1071 |

| Overall dimensions(LxWxH)(mm) | 1800x1350x1700 | 2810x2000x2115 | 2810x2100x2115 | 2810x2650x2115 |

| Weight(kg) | Approx 1600 | Approx 4460 | Approx 4560 | Approx 5464 |

| Model | SR1400 | SR1600 | SR2100 | SR2500 |

| Main shaft speed(rpm) | 73 | 73 | 73 | 73 |

| Ram travel(mm) | 820 | 1000 | 1000 | 1200 |

| Rotor diameter(mm) | Φ400 | Φ480 | Φ480 | Φ660 |

| Number of rotor blades(pcs) | 80 | 94 | 122 | 150 |

| Number of fixed blades(pcs) | 10 | 12 | 16 | 20 |

| Discharge height(mm) | 610 | 950 | 950 | 950 |

| Screen holes diameter(mm) | 40 | 40 | 40 | 40 |

| Motor power(kw) | 75~90 | 2x55~2x75 | 2x75~2x90 | 2x90~2x110 |

| Hydraulic power(kw) | 5.5 | 7.5 | 7.5 | 11 |

| Cutting chamber dimensions(mm) | 830x1302 | 1000x1533 | 1000x1995 | 1200x2457 |

| Overall dimensions(LxWxH)(mm) | 2810x2890x2115 | 3475x4100x2700 | 3475x4900x2700 | 3475x5400x2700 |

| Weight(kg) | Approx 6200 | Approx 10800 | Approx 13000 | Approx 16000 |