Corn Flakes Processing Making Equipment Line

Ningbo DSW International Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Concentration and Dry

- Automatic Grade:Automatic

- Application:Popcorn, Chips

- Customized:Customized

Base Info

- Model NO.:SLG65-III

- Model No.:Slg65-III

- Warranty:1 Year

- Capacity:100-150kg,H

- Material:Stainless Steel

- Product Name:Corn Flakes Processing Equipment

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Voltage:380-460V

- Power(W):90kw

- Dimension(L*W*H):20X2X4

- Export Markets:Global

- Transport Package:Standard Wooden Case

- Specification:CE

- Trademark:Jinan Datong Machinery Co., Ltd.

- Origin:Shandong Jinan

- HS Code:84361000

- Production Capacity:100-150 Kg,H

Description

Basic Info.

Model NO. SLG65-III Model No. Slg65-III Warranty 1 Year Capacity 100-150kg/H Material Stainless Steel Product Name Corn Flakes Processing Equipment After-Sales Service Provided Engineers Available to Service Machinery Overseas Voltage 380-460V Power(W) 90kw Dimension(L*W*H) 20X2X4 Export Markets Global Transport Package Standard Wooden Case Specification CE Trademark Jinan Datong Machinery Co., Ltd. Origin Shandong Jinan HS Code 84361000 Production Capacity 100-150 Kg/HProduct Description

Corn Flakes Breakfast Cereals Processing Line Factory Snacks Machinery

Specifications

1. Corn flakes/rice flakes making machine, snack food processing line equipment, snacks food processing machine, food extrusion machine, food extruder, food processor, puff food machine

2. Raw material: corn flour, rice flour, corn grits, millet and so on.

3. Product shapes: Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder. etc.

4. Capacity: 120-150kg/h; 200-250kg/h; 400-500kg/h; 600-900kg/h

1. Detail Description

Corn flakes/breakfast cereals are a kind of breakfast with high nutritional value. Corn, rice, wheat, oat, rye and other grains are usually used as materials, through mixing, extruding, flaking, drying, baking, coating and cooling, to produce extruded snacks, with crispy taste and lively shapes. It always service as breakfast cereal mixed with milk of coffee. But it can also be a kind of leisure snacks. This process line can also make other shapes of cereals such as rings, balls, square, stars, flowers, curls etc.

2. Technical parameters

| Model | Installed Capacity | Actual Consumption | Main Power | Throughput | Dimension |

| DT65 | 34kw | 28kw | 22kw | 120-150kg/h | 2400*1200*1800 |

| DT70 | 42kw | 30kw | 30kw | 160-200kg/h | 2600*1200*1800 |

| DT85 | 92kw | 75kw | 75kw | 400-500kg/h | 4500*1600*2000 |

| DT90 | 135kw | 91kw | 75kw | 600-900kg/h | 4500*2000*2000 |

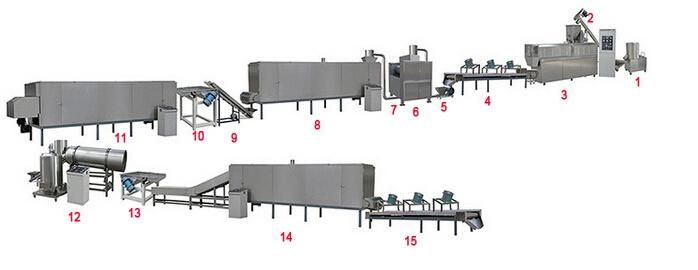

3. Production Line Flow Chart

Raw Material Mixing →Screw Extruder → Flaking → Drying →Sugar spraying → Drying → Packaging

4. Products Pictures

5. China standard industrial voltage for the machine

Three phases: 380V/50Hz, Single phase: 220V/50Hz, We can make it according to customers' local voltage according to different countries (400v, 415v, 480v, etc.).

6. Machines materials

All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

7. Packing & Shipping

Each machine is carefully packed. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottom. With this kind machine, all our laser machine can protect well during long trip by sea or by train.

10. FAQ

1. Q: Are you a trading company or a manufacturer?

A: We are the manufacturer, which has almost 10 years of experience in this industry.

2. Q: How can I get to your company?

A: That's great you can visit our factory, welcome! You can take a flight to Jinan International Airport, which is 30 minutes' drive from our factory. And we will pick you up.

3. Q: How long is your guarantee?

A: One year.

After this period we will definitely support you when needed.

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.