Coated Seed Dryer Machine

Shenzhen Xinhui Plastic Products Co., Ltd.- Type:Grain Coarse Cereals Processing Equipment

- Application:Flour, All, Beans, Wheat, Starch, Rice flour

- Voltage:380V

- Condition:New

- Customized:Customized

- Transport Package:Export Packaging

Base Info

- Origin:China

- Trademark:COYO

- Production Capacity:50000PCS,Year

Description

Item

Data

Model

BYH-5

Capacity (t/h) as wheat

5

Overall size(L×W×H),mm

4700×965×2260

Weight kg

800

Power(kW)

Gear motor

0.55×2

44.2

Heater

42

Fan

0.55x2

Fuel consumption (diesel oil)

3.5~5 L/H

Cylinder dia,mm

600

Cylinder rotation speed,rpm

32

Cylinder inclination angle

2-5°adjustable

Drying speed of coated sead

≥1%/h

4. Basic Structure And Working Principle

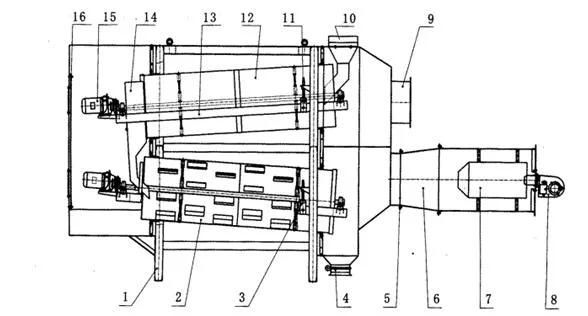

BYH-5 seed coating dryer is mainly composed of material feeding device, drying roller, hot air mixing chamber, combustion chamber, oil fired hot air stove, regulating device, frame and control system (Figure 1).

When the equipment works, first start the hot air control system, at the same time start the fan connected with the exhaust pipe, and then start the oil fired hot air stove to form the working hot air flow; then start the roller, the newly coated or pelleted seeds enter the upper and lower rolling fences in series through the feeding device, and the feeding amount can be manually adjusted; the materials entering the roller are brought up and slid down by the plate to form a uniform powder curtain, and the reverse Fully contact with the hot air, and gradually move to the low end of the drum; through the long-distance hot air drying of the upper and lower rollers, enter the discharge device and flow out, and the discharged materials can be truly measured, packaged and stored. A temperature sensor is arranged at the discharge end of the lower roller to automatically control the fire power of the oil fired hot blast stove.

1. Rack; 2. Lower drum; 3. Lower drum regulating device; 4. Discharging device; 5. Air distribution network; 6. Hot air mixing chamber; 7. Combustion chamber; 8. Oil fired hot blast stove; 9. Arch air duct; 10. Feeding device; 11. Upper drum regulating device; 12. Upper drum; 13. Drum support; 14. Lower drum feeding pipe; 15. Deceleration motor; 16. Observation window.

Packing Delivery

First, the brown rice is fed to rice polisher through screw head. the surface of the rice grain is polished by friction under a certain pressure and temperature. Through the polishing treatment, not only the floating surface of the rice grain can be cleared, but also the starch is pregelatinized and gelatinized on the surface of the rice starch, and the starch gelatinization makes up for cracks, thereby obtaining the smooth appearance, improving the storage life of the rice, therefore polished rice is very necessary.

FAQ

1. What is the delivery time of this machine if we book order right now?

We will deliver your order within 30-60days depend on different of machines.

2. How do you pack this machine for exporting?

We will provide packing which is suitable for the agreed means of transportation and for the foreseeable conditions of storage at the destination.

3. How can we make inspection before delivery?

We welcome you send your inspection manager come to our factory for inspection or you can nominate international the third part inspection company.

4. What is the warranty for your machine?

If any defect or non-conformity arising from faulty design, materials, we shall eliminate defects or replace machine.

5. What is the installation requirement of this machine?

The foundation of the machine should be with sufficient strength to support the weight of the machine.

There should be enough space around the machine for maintenance and inspection.