High Quality High Pressure Foam Machine Making Pillow

Anhui Easton Trade Co., Ltd.Base Info

Description

Basic Info.

Model NO. ZC-G40-1 Computerized Non-Computerized Certification CE, ISO9001:2008 Transport Package Plywood Box Specification 2500*1500*2500mm Trademark ZCE Origin China HS Code 8477800000 Production Capacity 50/MonthProduct Description

ZCE specialized in doing Polyurethane foam machine, Pu roller making machine, Polyurethane wheel and castor making machine, Polyurethane elastomer machine, MDI/TDI/NDI Polyurethane machine, Polyurethane injection machine, Polyurethane two components pouring machine,Three components polyurethane pouring machine, Polyurethane casting machine, PU machine, Polyurethane roll machine, Resin Casting Machine.

ZCE specialized in doing Polyurethane foam machine, Pu roller making machine, Polyurethane wheel and castor making machine, Polyurethane elastomer machine, MDI/TDI/NDI Polyurethane machine, Polyurethane injection machine, Polyurethane two components pouring machine,Three components polyurethane pouring machine, Polyurethane casting machine, PU machine, Polyurethane roll machine, Resin Casting Machine.

Technical Parameters

Low pressure PU foam

Mixing ratio adjustable

CE approved ISO approved

Making sandwich laminate panel , sandwich plate , laminate panel , decoration material

Functions and Features

1. Intelligent digital display meter, with temperature error: ≤±1ºC.

2. High-temperature resistant low-speed high-precision metering pump; accurate matching, flexible adjustment and measurement accuracy error: ≤±0.5%.

3. Special mixing device: rational design, reliable performance, patented mixing head, uniform mixing,; the ratio of graded

products is completely guaranteed.

4. Computer is used to control amount, automatic cleaning and air impact, with stable performance and strong operability

Low Pressure Polyurethane PU Foam Equipment Rigid Foam.PU Polyurethane Spray Foam Insulation Machine

| Item/model | PU20J-1T | PU20J-2T | PU20J-3T |

| Mixing ratio (A:B) | A:B=1:1 | A:B=1:1 | A:B=1:1 |

| Total discharge(Kg/min) | 1-5 | 3-12 | 10-30 |

| Machine head speed(r/min) | 4000-6000 | 4000-6000 | 4000-6000 |

| External dimension(length*width*height(mm) | 1700*1300*2400 | 1700*1300*2400 | 1700*1300*2400 |

| Total power(kw) | 8 | 9 | 9 |

| Weight (kg) | 1000 | 1000 | 1300 |

Output : 5~20g/min

- Three-phase AC 380V + zero line + (ground) frequency: 50HZ total power 35KW wire 10 square line

- Air source: The outer diameter of the inlet pipe is 8mm and the pressure is 0.6~0.8MPa.

- Three components mixing ratio: A: B = 80: 20

| Component Name | Mixing ratio | Temperature(ºC) | Viscosity (CPS) |

| A ( prepolymer) | 100 | 60-100ºC | <2000 |

| B (MOCA etc.) | 20-35 | 80-125ºC | <100 |

| C Color paste | 0.5-3 | Room temperature | 50-2000 |

Output : g/min

| Item/Model | CPU30J-M1 | CPU30J-M2 | CPU30J-M3 | CPU30J-M4 | CPU30J-M5 |

| Max.Output (g/min) | 250-2500 | 1000-5000 | 3000-10000 | 5000-15000 | 10000-30000 |

| A tank capacity(L) | 160 | 160 | 250 | 250 | 400 |

| B tank capacity(L) | 160 | 160 | 250 | 250 | 400 |

| C Tank Size(L) | 30 | 30 | 80 | 80 | 80 |

| Stirrer Speed(rpm) | 3000-5000 | 3000-5000 | 4000-5000 | 4000-5000 | 3000-5000 |

| Height from the ground(mm) | 1100-1400 | 1100-1400 | 1100-1400 | 1100-1400 | 1100-1400 |

| Total power(kw) | 30 | 30 | 35 | 35 | 40 |

| Weight(Kg) | 1800 | 2000 | 2500 | 2800 | 3200 |

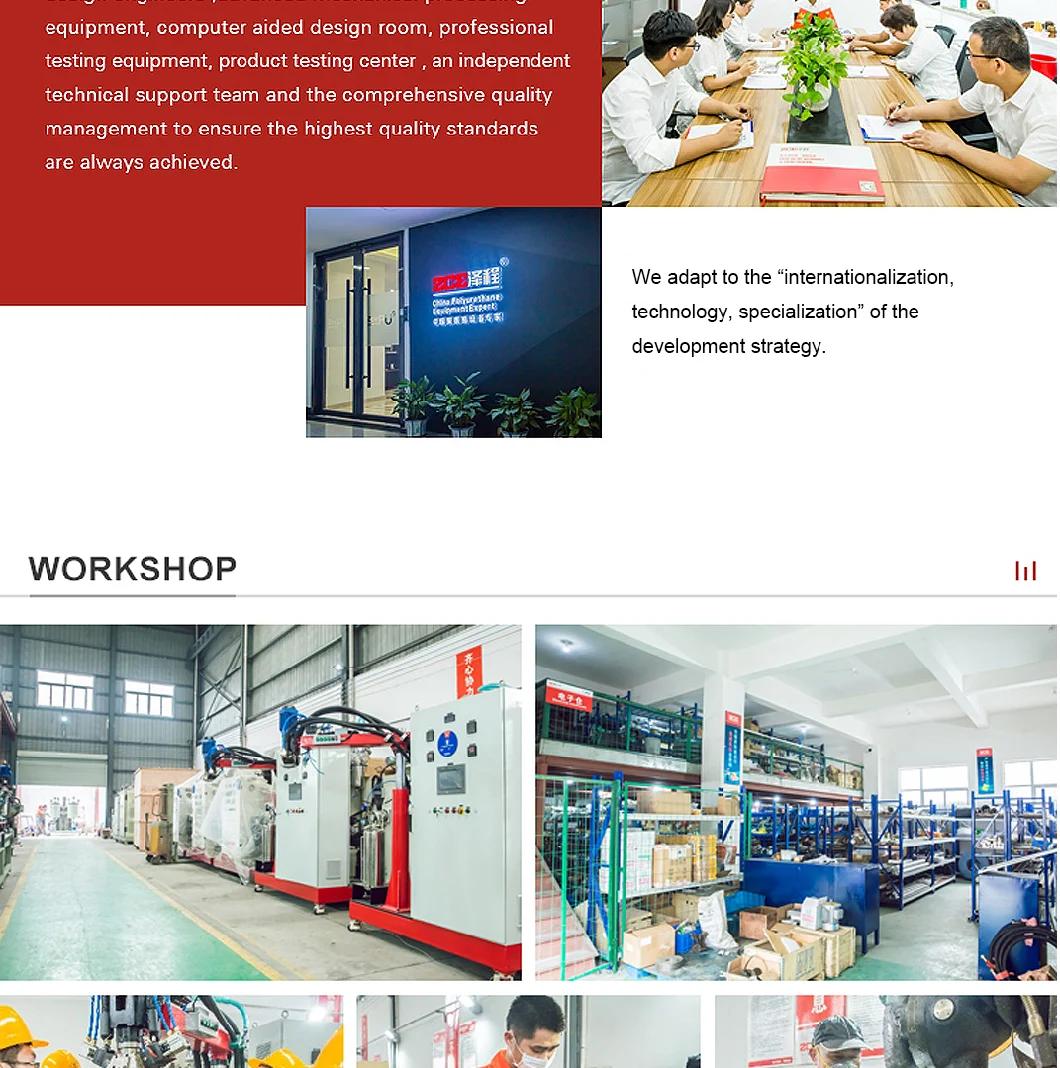

Company Information

Certificate

Packaging

FAQ