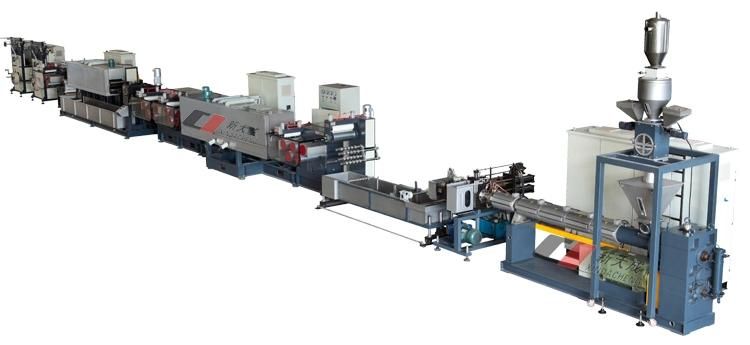

Pet Strap Packing Band Extruder

Zhejiang Longyou Huiyang Foreign Trade Co., Ltd.Base Info

Description

Basic Info.

Model NO. XDC Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Weight 20t Transport Package Wooden Specification 45*5*5 Trademark XDC Origin Qingdao Production Capacity 12piece/YearProduct Description

PET strap, also known as plastic steel band, which is used in place of steel on the world of a new environmentally friendly packaging materials, the development of new materials in recent years the cost of success and a substantial decline, have been widely used in the steel industry, chemical fiber industry, aluminum ingots, paper, brick kiln industry, screw industry, tobacco industry, electronics, textiles and wood, etc.; Is replaced by a new high-strength steel strapping, is the world's most widely used for steel products.

PET strapping band production line consists:

1. SHR-1500 Crystallizing and Drying and I. V increasing unit

2. Twin screw extruder

3. Screen changer

4. Gear pump

5. Mould

6. Water cooling tank

7. Pre-heating unit No. 1

8. Stretching oven

9. Stretching unit No. 1

10. Stretching unit No. 2

11. Embossing unit

12. Fixing unit

13.3-roller hauling off

14. Winder

Characteristic:

Choice of single or twin screw extruder.

Production can use 100% recycled material to obtain a high add value commodity like strapping band.

PLC manages automatically the extruder's working parameters in according with the running condition; Material treatment, extrusion, stretching, annealing and taking up units are all synced with the PLC.

All components are controlled and monitored through PLC.

PET or PP straps can be produced with the same technology, to change line set-up from one to the other only take in few minutes.

High-advanced ABA co-extrusion technology, not only improve strap's tensile strength but also help the peel strength after welding.

Double column 4 positioned filter chambers, 100% full automatic self-cleaning screen changer, working non-stop during screen changing, it ensures the straps quality is not affected throughout the production.

Choice of ordering one, two, four, six and eight straps production line.

Choice of either servo or torque motor for winding machine.

| Strap width | 9-32mm |

| Production speed | 160m/min |

| Stretching ratio | 4-6 |

| Max.output | 200-600kg/h |