PVC Imitation Marble Sheet Extrusion Production Line for Flooring/Countertop/Kitchen ...

Forsun Ultra-hard Material Industry Co., Ltd.Base Info

Description

Basic Info.

Model NO. SJSZ80/156 Certification CE, ISO9001:2008, UL, QS, GMP Customized Customized Dimension (L*W*H) 27m*2.8m*2.3m PLC Siemens Main Motor Siemens Converter Siemens Transport Package PE Wrapping Film, Fumigating Wooden Cases Specification CE, SGS, UL, CSA Trademark BOYU Origin Wuxi, Jiangsu, China HS Code 8477209000 Production Capacity 50 Lines/YearProduct Description

PVC Imitation Marble Profile Extrusion Production LinePVC imitation marble profile characteristics:

A, the surface is smooth, mirror effect;

B, the surface film color is rich, you will have more choices;

C, the material have no formaldehyde, surface color treatment without solvent and benzene;

D, because the color is hot stamping processing, surface is light oil processing, no color difference , have a good weatherability;

E, surface is UV processing, product is wear resistance and impact;

F, UV treatment surface is corrosion preventive.

I. PVC Imitation Marble sheet extrusion production line for Flooring/Countertop/Kitchen IslandDesign parameters

| No. | Items | Data |

| 01 | Operation Conditions | 380V/3 phases/50Hz, DC24V. |

| 02 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant |

| 04 | Main material proportion | PVC: CACO3= 1:3 |

| 05 | Product specifications | Width:1220mm,Thickness:1-8mm |

| 06 | Extrusion line mode | SJSZ 80/156 conical twin screw extrusion line |

| 07 | Quality standard | Twin screw standard JB6492-2001 Electricity standard: GB5226.1-2008/IEC 60204-1:2005 |

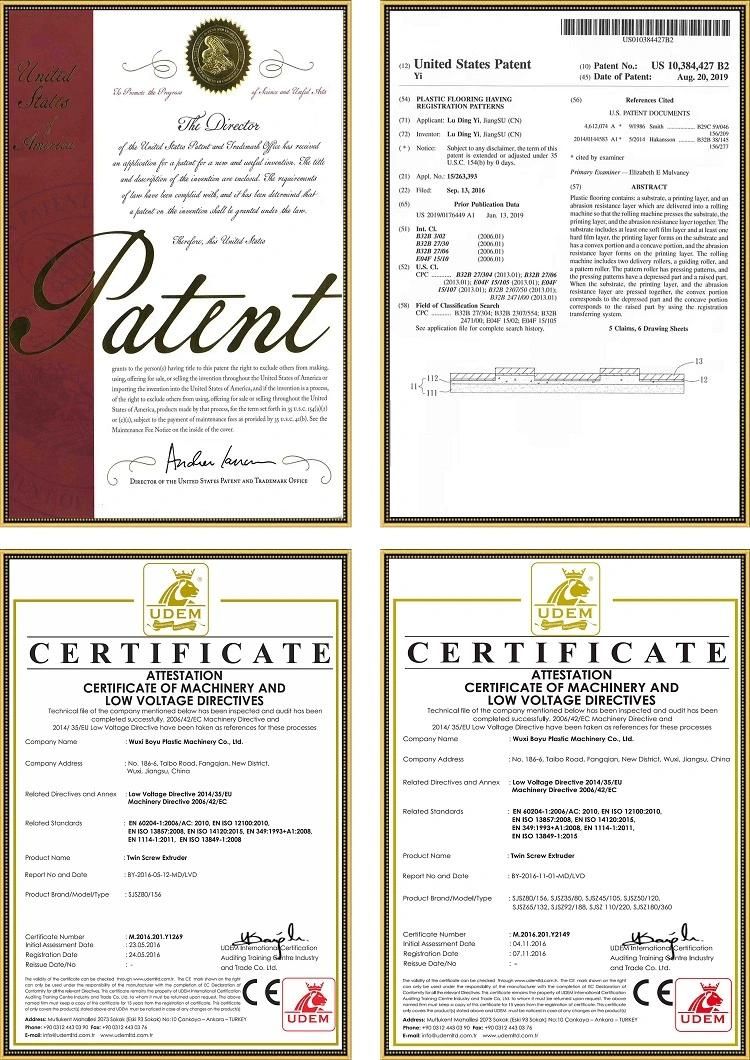

| 08 | Machine Fabrication Certificate | CE /UL |

| 09 | Electric components certificate | CE /UL /CSA |

II.PVC Imitation Marble sheet extrusion production line for Flooring/Countertop/Kitchen Island Equipment List & Quantity

| No. | Equipment Name | Quantity | Remark |

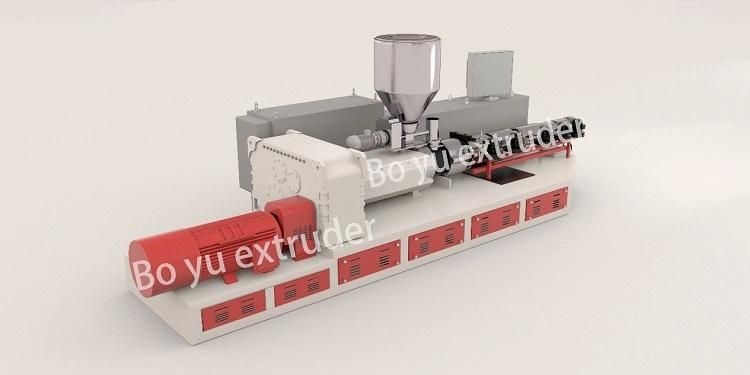

| 01 | Φ80/156 Conical twin-screw extruder | 1 Set | |

| 02 | Extrusion die | 1 Set | |

| 03 | Three-rollers calender | 1 Set | |

| 04 | Film unwinding mechanism & magnetic powder controller | 1 Unit | For two working position |

| 05 | Oil rollers heating system | 1 Set | 4 units |

| 06 | Cooling bracket | 1 Unit | |

| 07 | Longitudinal edge cutting mechanism | 1 Unit | |

| 08 | Traction machine | 1 Set | |

| 09 | Length meter | 1 Set | |

| 10 | Plate shearing machine | 1 Set | |

| 11 | Automatic stacker | 1 Unit | |

| 12 | Electric control cabinet | 1 Unit |

III. PVC Imitation Marble sheet extrusion production line for Flooring/Countertop/Kitchen Island Production process:

The screw feeder takes the material from the 5m3 silo(~ 3 tons) → The Extruder Feeding Hopper → The extruder → Material plasticizing → T-die → The Three-rollers Calender →Edges Trimming → Roller Cooling Bracket →Air Cooling Cabinet(Optional) → Traction Machine→ Cutting Machine →Automatic Flipping & Stacking Machine

IV. PVC Imitation Marble sheet extrusion production line for Flooring/Countertop/Kitchen Island Main technology parameter of extruder

- Conical Twin-screw Extruder

| Extruder Model | Capacity/24h | Capacity/h | 4mm Linear Speed |

| SZJZ-80 | 6-8T | 250-350KG | 0.4-0.6m/min |

| SZJZ-92 | 8-12T | 500-700KG | 0.8-1.3 m/min |

V. PVC Imitation Marble sheet extrusion production line for Flooring/Countertop/Kitchen Island Finished Products

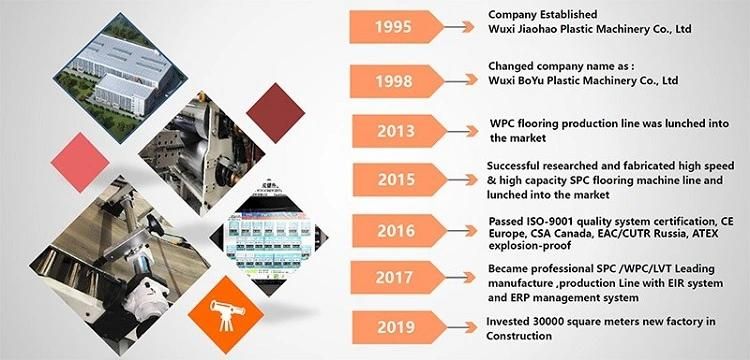

VI. PVC Imitation Marble sheet extrusion production line for Flooring/Countertop/Kitchen Island Boyu Company Profile

VII. Our Services:

VIII. Shipping

IX. Patents