27moulds Automatic Wafer Biscuit Production Line

Taizhou Huangyan Yuno Mould Co., Ltd.- Certification:CE, UL, ISO9001

- Power Source:Gas

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Chocolate, Biscuit, Wafer Biscuit

- Customized:Customized

Base Info

- Model NO.:model-27

- Warranty:1 Year

- Key Selling Points:High Productivity

- Application Fields:Bakery, Snack Food Factory

- Voltage:220V,380V

- After-Sales Service:Engineers Available to Service Machinery Overseas

- Applicable Industries:Manufacturing Plant, Food & Beverage Factory

- Material:304 Stainless Steel

- Power(W):Depends on Model

- Bearing:Japanese Brand NSK

- Moter:Germanry Brand Sew

- Control Panel:Germanry Brand Siemens

- Main Control Apparatus:French Brand Schneider

- Transport Package:Super Stronger Woodern Case

- Specification:6000*1700*2400mm

- Trademark:skywin

- Origin:Guangdong, China (Mainland)

- HS Code:8438100010

- Production Capacity:80-240kg,H

Description

| Mold | 27 | 31 | 33 | 39 | 45 | 51 | 65 | 69 | 71 |

| Baking Oven Length(mm) | 6000 | 6750 | 7150 | 8300 | 9450 | 10600 | 13300 | 14000 | 14400 |

| Whole Line Length(mm) | 22000 | 22750 | 23150 | 24300 | 25450 | 26600 | 29300 | 30000 | 30400 |

| Power(kw) | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 |

| LPG(kg/h) | 13 | 15 | 15 | 19 | 23 | 27 | 32 | 35 | 37 |

| LNG(m3/h) | 16 | 19 | 21 | 25 | 30 | 35 | 45 | 47 | 50 |

| Electrical Heating Power(kw) | 90 | 105 | 110 | 130 | 150 | 270 | 215 | 230 | 235 |

| Capacity(pcs/min) | 14 | 16 | 17 | 20 | 23 | 26 | 33 | 35 | 36 |

Need More machine price or Video?

Send Inquiry to us directly!____________________________________SKYWIN Brand Wafer making machine has many models like 27Plates, 33Plates, 39Plates, 45Plates, 51Plates, 63Plates, 69Plates, 75Plates etc. The plates quantity can be customize.

SKYWIN Brand Wafer making machine is aviable for all kinds of Wafer biscuit.

The capacity of the whole line is from 80kg/h to 250kg/h

Wafer Baking Machine Wafer Biscuit Production Line

The wafer baking system uses LPG or LNG for heating of the baking plates.The function of the baking oven is fully automatic from spreading batter on the plates

through until baked wafer sheets come out of the oven. Baking is even and produces

good quality wafer sheets for next procedure.

In PLC there is PID controller which is used for controlling the temperature of the baking plates automatically .

The collection of required signal of PID is supplied by infrared sensor .

The oven status display and the data reset are supplied by a touch screen, all motor

have the starting current protection and thermal overload protection.

Fully Automatic wafer making machine consists of followed machines:

1.Full Auto Wafer Batter Mixer2.Cream mixer

3.Baking oven+Sheet Receiver

4.Cooling Machine

5.Sheet Picking machine

6.Cream Spreading machine (Two colors+Horizontal Cooling Cabinet +Laminating

7.Machine

8.Cutting Machine

9.Smashing machine

10.Electric Control Cupboard.Certifications

FAQ

1.Q:Are you manufacturer?

A: Yes, we are factory specialized in Wire cutting cookies machine , and have group of 20 years experienced engineers, advanced processing equipments.

2.Q: How dou you ship the products?

A: Usually by sea, but can also according to customer requirements.

3.Q: What is your mini order quantity?

A: 1set.

4.Q: What information should I provide, if I want a quotation?

A: ---the kind of machine you choose, or offer me the kinds of biscuit you will produce.

--- your production capacity requirement.

---provide us your production details, then we give professional suggestion to you.

5.Q: Why choose us?

A: ---We are China leading snack food machinery supplier.

---Alibaba assessed supplier.

---Best quality & best service with competitive price.

6.Q: Is there a variety of language options for your operating system?

A: We use PLC controller system, it has Russian, English, Chinese, Korean, Arabic and other languages.

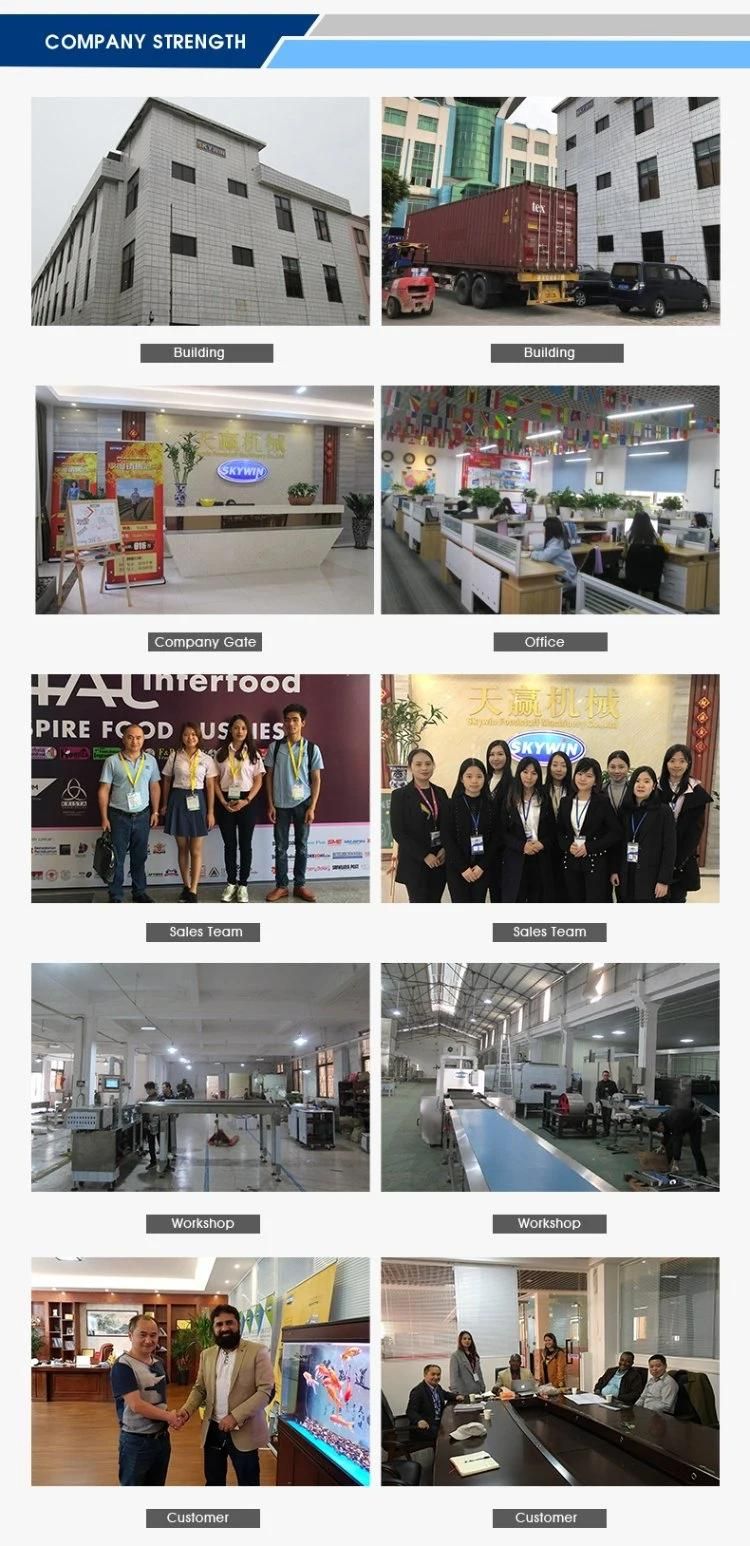

Company information