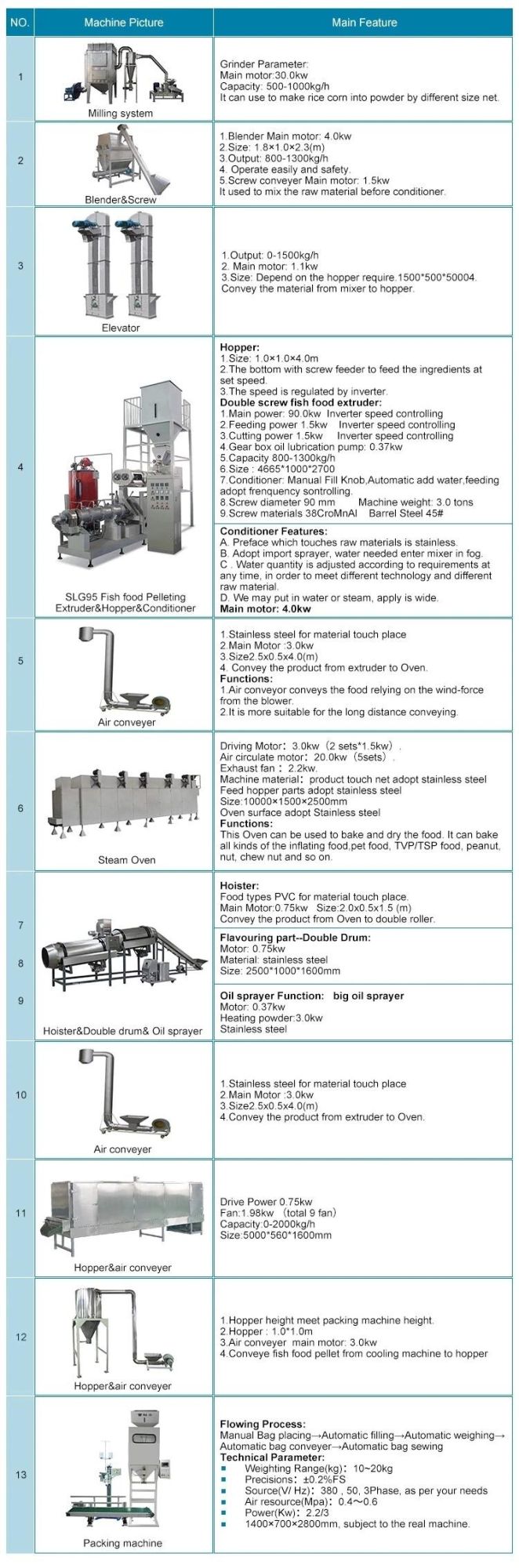

Small Floating Sinking Tilapia Fish Feed Pellet Machine Price Fish Food Extruder

Ningbo DSW International Co., Ltd.- Power Source:Electric

- Process:Concentration and Dry

- Automatic Grade:Automatic

- Application:Dog, Fish, Cat, Bird

- Feed Type:Fish Meal

- Customized:Customized

Base Info

- Model NO.:DT90

- Stainless Steel Material:201,304

- Motor Brand:Siemens

- Inverter:Delta

- Electricity Parts:FUJI LG Delta

- Line Size:50.0*5.0*6.0

- Manager:Mr.Kevin Lee 0086-15264102980

- Capacity:500-1000kg,H

- Warranty:1 Year

- Model No:Dt90

- Transport Package:Woodcase

- Specification:CE ISO BV SGS

- Trademark:Jinan Datong Machinery Company

- Origin:Jinan

- HS Code:843800000

- Production Capacity:800-1000kg,H

Description

Name

Small floating sinking tilapia fish feed pellet machine price fish food extruder

Material

Stainless steel and carbon steelTop quality floating fish feed extruder machine Tilapia Fish Feed Pellet Machine Mill Twin Screw Fish feed pet food extruder

Whole line Size:

weight:

6000-7000kg

working Power

380v 50HZ three phase (Customized)

Packing way

woodcase or plastic film

Payment

T/T or L/C at sight

Shipment date

in about 40-50 days

Advantage

1. The finished pellets can keep floating more than 10 hours.

2. The floating time can be controlled by the puffing degree adjustment.

3. Fish feed processing line can make pellet from 1.0mm-15mm just by changing the mold.

4. Electric heating device is adopted which can improve the feed expansion rate and pellets

floating time.

5.SLG90 dry fish feed pellet wet pet food making machine in our factory:

Our company engineer go to customer factory to help them and training workers on the spot.

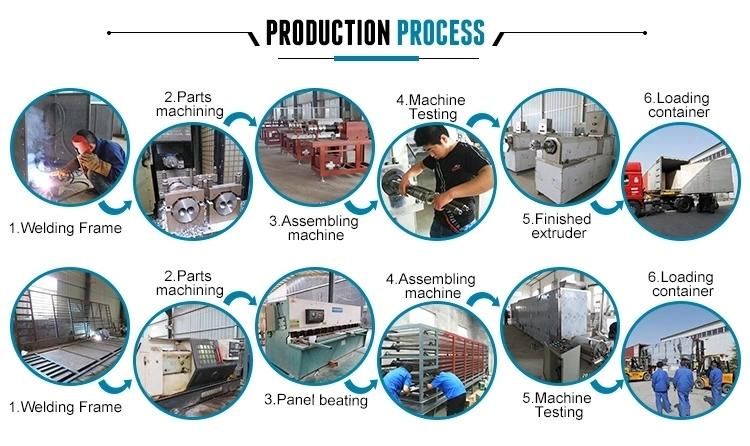

JINAN DATONG EXTRUSION MACHINERY Co., Ltd is an industry and trade integrated enterprise. The company is committed to R & D extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system,soy nuggets system; as well as pet food/fish food system.

1)Free management of equipments' long distance shipping;

2)Provide factory layout according to your factory size in advance;

3)Provide the basic formula;

4)Inspect the machine before leaving the factory;

5)Oversea installation and commissioning the equipment;

6)Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working;

7)Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever;

8)Provide English Version of Installation/Operation/Service/Maintenance Manual.

8.Packaging & Shipping

1. Inside package is plastic film, outside is wooden or plywood case, or fumigation package with certificate, (based on the customers' need).

2. Ship, train, express or upon clients' demands.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.