-

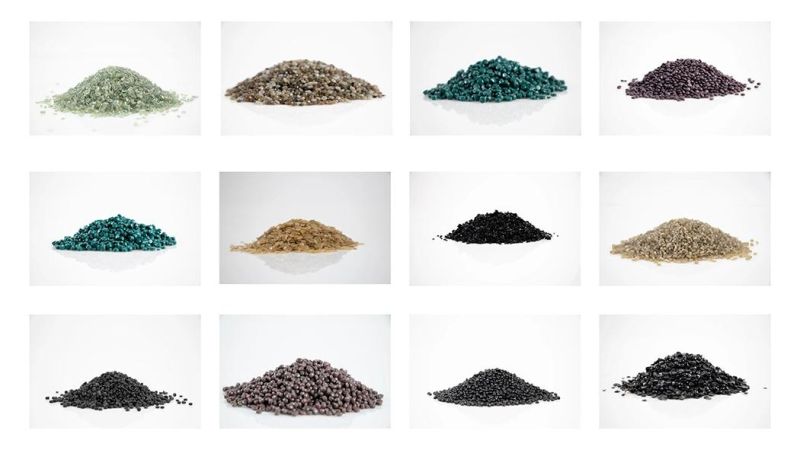

Warm Service Extruded Agglomerator Machine for PP PVC LDPE Film Granules

Overview Product DescriptionProduct ParametersSuitable ProductsFinal ProductsDetailed PhotosCONTACT USCompany ProfileFAQCONTACT US

-

Full Automatic Pure Water Bottle Making Machinery Pet Blow Molding Machine

MachineMain body dimension(L*W*H)m1.5*0.65*2.01.5*0.65*2.01.5*0.65*2.02.1*0.75*1.6Main body weightkg600550550900Pre-heater(L*W*H)m1.5*0.65*1.51.4*0.65*1.51.8*0.65*1.52.7*0.7*1.6MachineFeaturesA. Stable performance with advanced PLC.B. Conveying preforms automatically with conveyor.C. Strong penetrab

-

Plastic Medical Bed Accumulation Type Blow Molding Machine

extruder1Screw diameter100mm2L/D ratio24:13Screw speed15~50r.p.m.4Drive motor45Kw5Heating zone with cooling fan6 zone6Output/Capacity170 Kg/hr(HDPE particle)8Heating capacity25.1 kw9Vertical adjustment of head500mm10Forward/Backward adjustment of head500mm11Groove feed barrel cylinderHave IKV12Gear

-

PVC Ceiling Making Machine

Compulsory devices1Material charge1 set2Conical twin screw extruder SJSZ-65/132, 80/156, 92/1881 set3Extrusion die head16-800mm, 1set or several sets4Vacuum calibrating table1 set or several sets5caterpillars hauling off machine1 set6Saw cutting machine1 set7stacker-6000mm length1 set8Electrical cab

-

Medical Bed Board Accumulation Type Blow Molding Machine

extruder1Screw diameter100mm2L/D ratio24:13Screw speed15~50r.p.m.4Drive motor45Kw5Heating zone with cooling fan6 zone6Output/Capacity170 Kg/hr(HDPE particle)8Heating capacity25.1 kw9Vertical adjustment of head500mm10Forward/Backward adjustment of head500mm11Groove feed barrel cylinderHave IKV12Gear

-

Full Automatic Blow Molding Machine for Making Medical Bed Board

extruder1Screw diameter100mm2L/D ratio24:13Screw speed15~50r.p.m.4Drive motor45Kw5Heating zone with cooling fan6 zone6Output/Capacity170 Kg/hr(HDPE particle)8Heating capacity25.1 kw9Vertical adjustment of head500mm10Forward/Backward adjustment of head500mm11Groove feed barrel cylinderHave IKV12Gear

-

Automatic Medical Bed Board Blow Molding Machine

extruder1Screw diameter100mm2L/D ratio24:13Screw speed15~50r.p.m.4Drive motor45Kw5Heating zone with cooling fan6 zone6Output/Capacity170 Kg/hr(HDPE particle)8Heating capacity25.1 kw9Vertical adjustment of head500mm10Forward/Backward adjustment of head500mm11Groove feed barrel cylinderHave IKV12Gear

-

PVC Ceiling Extrusion Line

Compulsory devices1Material charge1 set2Conical twin screw extruder SJSZ-65/132, 80/156, 92/1881 set3Extrusion die head16-800mm, 1set or several sets4Vacuum calibrating table1 set or several sets5caterpillars hauling off machine1 set6Saw cutting machine1 set7stacker-6000mm length1 set8Electrical cab