Sjsz-80/156 PVC Waterproof Floor Sheet Making Machine

CHINA GTL TOOLS LIMITEDBase Info

Description

Basic Info.

Model NO. SJSZ-80/156 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized PVC Floor Type Waterproof Floor Rolls Width of Floor 2000mm Thickness 0.75-5mm Structure Two, Three, Five Layers Transport Package as Export Standard Packing Specification SJSZ-80/156 Trademark WEIER Origin China HS Code 84772090 Production Capacity 600kg/HProduct Description

pvc wide floor leather production line pvc waterproof sheet / rolls production line

We have running pvc wide water-proof flooring rolls production lines in China!

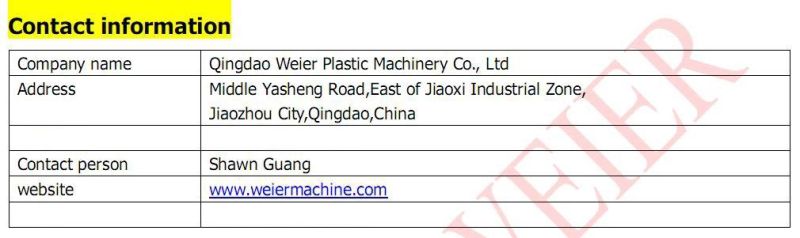

If you are interested in our pvc flooring production machine line, pls be free to contact with me:

CONTACT: Shawn

Cellphone : 0086-15853232639

This production line is mainly used for the production of sorts of PVC flooring leather and PVC waterproof rolls.

Features of pvc wide flooring rolls:

PVC flooring leather products have features such as wear-resistance, erosion-proof, skid resistance, seepage-proofing, antiflaming, etc. It is widely used for haulage motor, hotel, restaurant, amusing hall, exhibition hall, houses, etc.

Application of PVC wide flooring rolls:

PVC water proof rolls can be applied well for water proof of various roofing in industry and construction, etc; and construction water proof project in basement, reservoir, waste water treatment, etc.

Main specification of pvc wide leather flooring rolls production line:

type | double layers | three layers |

product width | 1500-2000mm | 2000-3000mm |

extruder model | SJZ-65/132- SJZ-80/156 | SJZ-65/132-SJZ-80/156-SJZ-65/132 |

max. capacity | 150-500kg/h | 600-750kg/h |

main motor power | 37kw/55kw | 37kw/55kw/37kw |

Composition of pvc wide flooring rolls extrusion line/ pvc waterproof floor sheet making machine:

item | Equipment list | QTY |

1.1 | Conical twin screw extruder WRSJ-80/156 | 1 set |

1.2 | Conical twin screw extruder WRSJ-65/132 | 1 set |

1.3 | Co-extrusion T type mold and distributor | 1 set |

1.4 | Three roller calendaring machine | 1 set |

1.5 | Roller temperature controller | 1 set |

1.6 | Cooling conveying bridge with trimming device | 1 set |

1.7 | Rubber rollers haul off machine and automatic cutter | 1 set |

1.8 | Automatic winder | 1 set |

1.9 | Electrical control system | 1 set |

1.10 | SHRL-300/600 high speed cooling mixer | 1 set |

1.11 | SHRL-200/500 high speed cooling mixer | 1 set |

1.12 | Depicting roller ( shall be ordered separately) |

Photos of PVC wide leather flooring production line for reference: