PP Shopping Bag Pelletizing Machine Plastic PE LDPE Film Single Stage Granulating Line

Dongguan Yize Precision Cutting Tool Co., Ltd.Base Info

Description

Crushing and compacting of PP PE granulating line

Crushing and compacting of PP PE granulating lineCompactor is equipped with air exhausting device. With the mechanical work of rotor knife and stator knife at the bottom of compactor, the temperature of compactor and material will gradually increase after continuous cutting and friction, and the moisture and dust on the surface of raw material will float to the top of compactor. The device can effectively remove moisture and dust, which will avoid using additional energy consumption to deal with the moisture.

Plasticization and degassing of PP PE granulating line

Plasticization and degassing of PP PE granulating lineA specialized single screw extruder applied to gently melt the pre-compacted material. the plastic scraps will be well melted, plasticized in a 34d to 36d processing section. with double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with water content.

Melt filtration screen exchanger of PP PE granulating line

Melt filtration screen exchanger of PP PE granulating lineA regular single-plate/ piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on head of extruder to present significant filtration performance. the requirements on the filter echnology depend heavily on the quality of the input material as well as the planned use of granules.

Pelletizing of PP PE granulating line

Pelletizing of PP PE granulating lineDie-face water ring pelletizing system set as the standard granulating method in this system. self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. The production line can be equipped with three kinds of granulation methods: water circumferential cutting, water-cooled stretching, automatic stretching or underwater granulation.

Vibrator of PP PE granulating line

Vibrator of PP PE granulating lineChoosing the proper sizes' pellets.

Storage hopper of PP PE granulating line

Storage hopper of PP PE granulating lineCollecting the pellets, then put into the proper packages.

6. PP PE granulating line Machine Advantages:

1.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time and no second pollution to flakes.

2.World famous brand components applied on the production line- NSK bearing, Siemens contactor, Omron temperature, FUJI inverter, Siemens PLC control etc.

3. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

4.The whole production equipment is researched, design and manufactured by our company with CE certification, ISO9001 certification; it can be designed based on the dirty flakes, and make sure of the quality of the final products.

7. PP PE granulating line Machine Workshop:

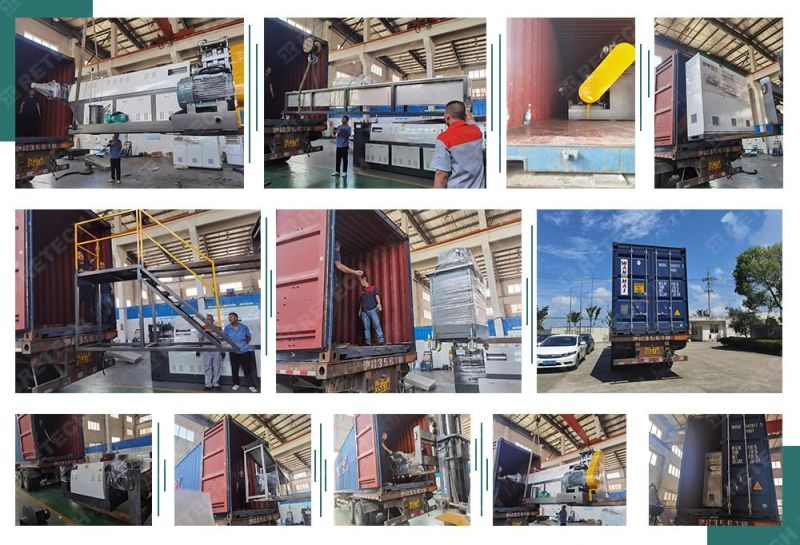

8. PP PE granulating line Company Profile: 9. PP PE granulating line Machine Packaging Shipping:

9. PP PE granulating line Machine Packaging Shipping:

10. PP PE granulating line Sales Service:

Service Before Sale

1. 24 hours online. Your inquiry will be quick reply by email. Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

1. Free insurance for goods.

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.