Base Info

Description

Basic Info.

Model NO. HSD960-1680 Customized Customized Condition New After-sales Service 6-12 Monthes Extruder Sj-75/33 Produce Speed 1-6m/Min Output Capability 300-350kg/H Transport Package Wooden Pallet/Plastic Film Specification pipe dia. 110-600mm Trademark Huashida Origin Qingdao HS Code 84772090 Production Capacity 100sets/YearProduct Description

960-1680mm PU foaming preinsulation pipe of HDPE jacket shell casing extruder machineModel: 960-1680mm

Raw material & formulation: HDPE pellets

Total length of the line: 45m

Total power : about 560KW

Extruder: SJ-150/33

Output capability: 4000-1200kg/h

Introduction:

1. High-effeciency single screw extruder

Single screw is with barreir & mixing head; barrel is new model with slotting (channel), Both make security of good jellification, large output and stable performance.

Vacuum forming tank is mainly composed of frame, stainless steel tank, vacuum system, spray cooling system, back and forth mobile device. When it is at work, the vacuum pump exhausts the air from the sealed tank to pressurize the fresh pipe cling to calibrating copper sleeve and to realize calibrating the pipe outer diameter. Spray cooling system is used to cool down the extruded pipe by water. Spray nozzles spray cooling water from all directions on pipe surface to cool down the pipe promptly.

Main machine line composed

| No. | Name | Qty. |

| 1 | Hopper dryer & vacuum loader | 1set |

| 2 | SJ150/33 High-efficiency Single Screw Extruder | 1set |

3 | Die head & Mould & Calibrator | 1set |

| 4 | Vacuum calibration tank 6000mm | 1set |

| 5 | Water cooling tank 6000mm | 1set |

| 5 | twelve-caterpillar Haul-off | 1set |

6 | Planetary cutting machine(Including dust catching device & ellipse correction) | 1set |

| 7 | Stacker | 1set |

| 8 | PLC central controlling system | 1set |

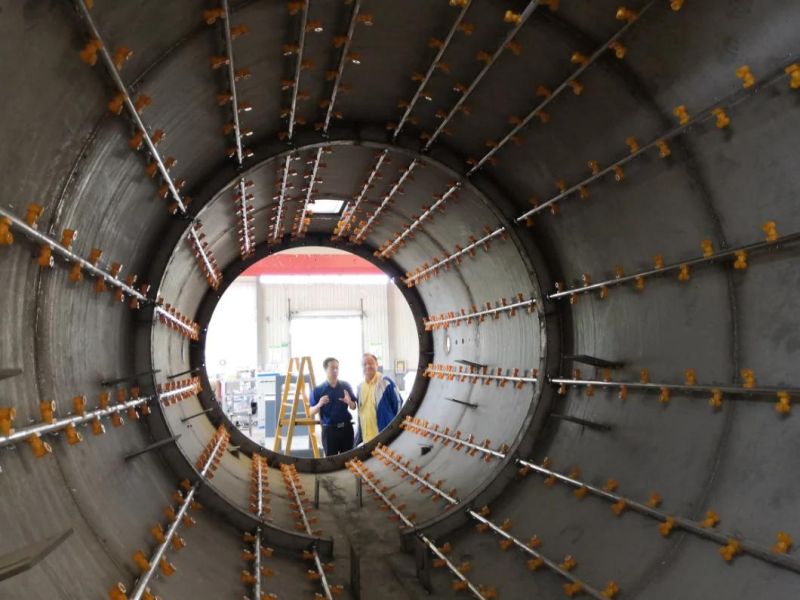

WORKSHOP

Client Visiting

Delivery

Certification

Welcome you contact us to know more detail !