Wood E Waste Plastic Rubber Metal Steel Scrap Shredder Machine

Amax Industrial Group China Co., Ltd.Base Info

Description

Basic Info.

Model NO. XS400 Computerized Computerized Certification ISO9001:2008, CE, ISO, CE Type Scrap Metal Shredder Transport Package Wood Case Specification by custom Trademark XINMECHAN Origin China Production Capacity 2000 PCS/MonthProduct Description

Brief introduction

The shredder is also known as the shredder crusher, reduces the size of the shredded material by cutting, tearing and squeezing.

How the shredder works

The shredder uses a gear motor directly connected to the worm, directly mounted on the active shaft of the shredder. The speed of drive shaft is varied through the gear transmission, so that the main drive shaft spiral tooth plate forms a relative motion. The spiral tooth discs on the main drive shaft are staggered so that the material entered will be squeezed, torn and cut, thus broken to smaller particles.

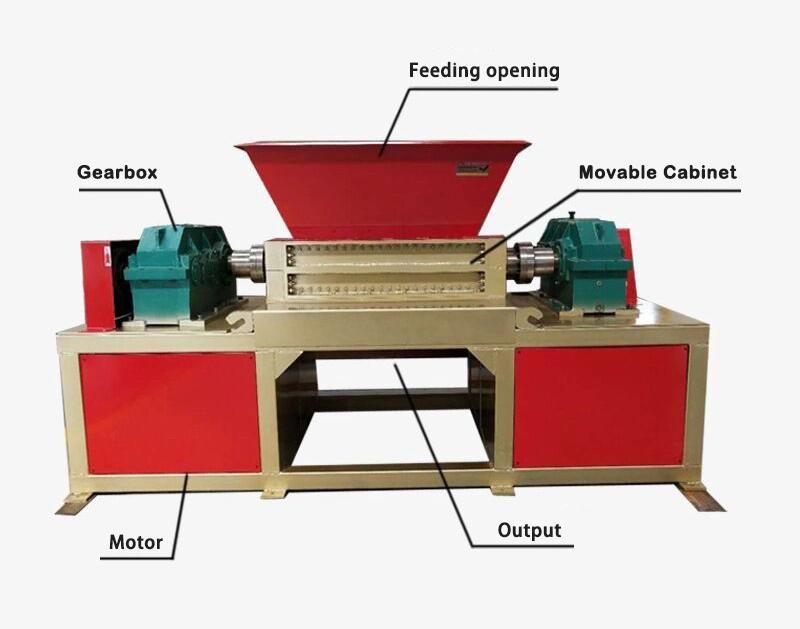

Parts of the shredder

1. Body

The main body of the equipment is produced in the whole one, using high-quality steel plate welding to eliminate the stress, to ensure the stability of the equipment in the long heavy load.

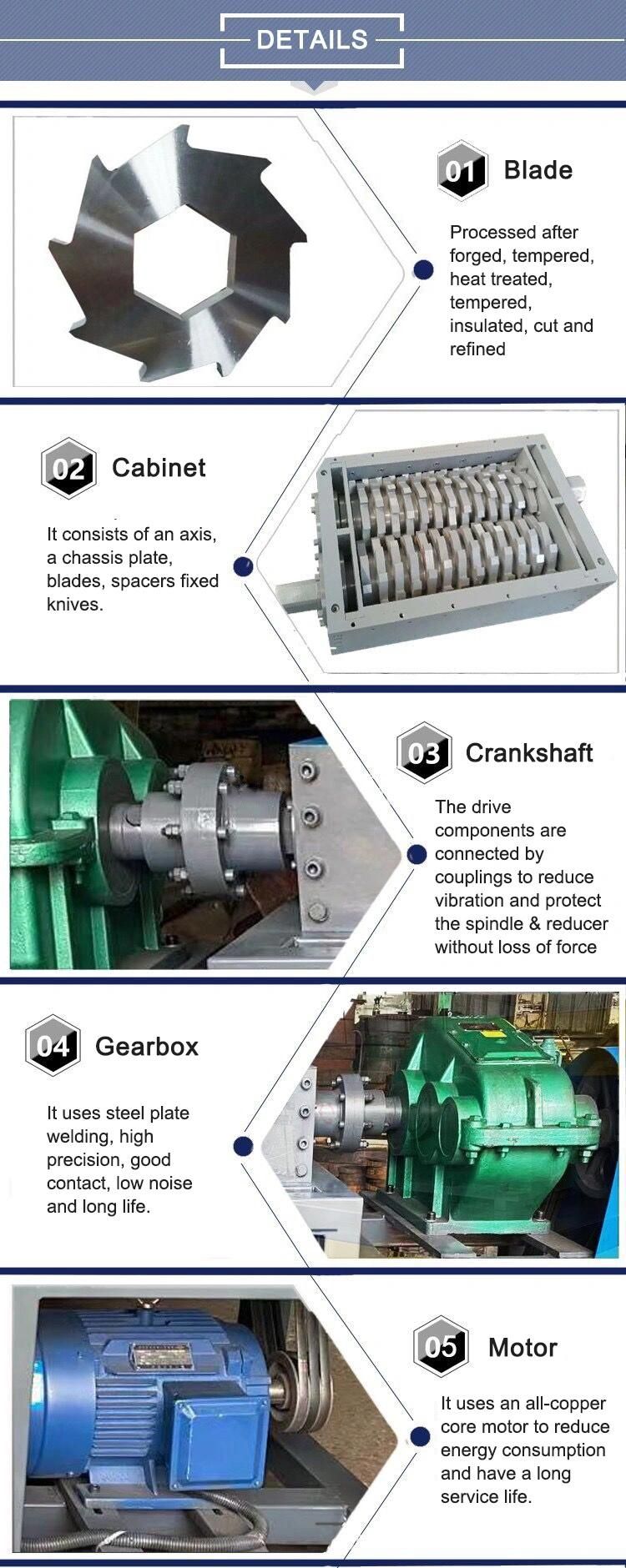

2. Movable knife / fixed knife

The tool material is made of alloy tool steel forging blanks, precision machining through multiple heat treatment and low temperature frozen heat treatment technology, and the overall toughness hardness is consistent, can be repaired repeatedly to ensure the performance and service life. The fixed knife is mounted with hooks to optimize the tool replacement function and make tool maintenance replacement more efficient.

3. Bearings/seals

The housing is flattened and disassembled, can quickly remove movable knife, fixed knife, bearing and other components, easy to maintain and replace tools. The unique sealing structure effectively blocks the contact between broken materials and grease. Even if shredding liquid materials, the bearings and gears can also be protected.

4. Knife shaft

The knife shaft is made of high-strength heavy-duty steel material, more reasonably match with tools for cutting to provide a strong power.

Application

The shredding machine is used for shearing urban household waste, solid hazardous waste and industrial solid waste etc.

Shredder performance features

1. This product can shred large blocks of material, basket material, pipe, sheet, wood, tires, scrap metal barrels, large roll film which a shaft shredder is difficult to break.2. The outer frame is of thick plate precision processing of the combination of the structure, with large angle hexagonal column of the powerful rotating shaft, large caliber solid input hopper. So you can rest to throw large-scale raw materials into the machine.

3. The rotary knife is designed and processed under consideration of the thickness, shape, order and other aspects, ensuring high strength, sharp blade with excellent work performance.

4. The machine is operated with low noise, less dust.

5. The tool blades are made by special alloy steel, durable.

Specification sheet

| Model | Knife spec. (mm) | Power | Blade Qty | Transmission | Rotary speed | Overall size(m) |

| 300 Type | Φ100*20 | 3kw | 12 | 250 | 13-20 | 1.2*0.45*1.2 |

| 400 Type | Φ200*20 | 4kw | 18 | 250 | 13-20 | 1.3*0.5*1.25 |

| 450 Type | Φ160*20 | 5.5kw | 20 | 250 | 13-20 | 1.35*0.57*1.3 |

| 500 Type | Φ200*20 | 7.5kw | 25 | 300 | 13-20 | 1.7*0.55*1.35 |

| 600 Type | Φ220*20 | 11kw*2 | 30 | 300*2 | 13-20 | 2.4*0.85*1.45 |

| 600D | Φ260*20 | 15kw*2 | 30 | 300*2 | 13-20 | 2.4*0.85*1.45 |

| 800 Type | Φ200*20 | 15kw*2 | 32 | 400*2 | 13-20 | 2.15*0.87*2.2 |

| 1000 Type | Φ300*25 | 30kw*2 | 32 | 650*2 | 13-20 | 3.4*1.25*2.2 |

| 1200 Type | Φ400*30 | 55kw*2 | 38 | 650*2 | 13-20 | 4.15*1.25*2.2 |

| 1500 Type | Φ400*30 | 75kw*2 | 48 | 750*2 | 13-20 | 4.15*1.25*2.2 |

| 2000 Type | Φ530*50 | 90kw*2 | 38 | 850*2 | 13-20 | 5.25*1.78*2.2 |

Above parameter sheet is just for your reference.

The final specification will be adjusted according to buyer's actual requirement, such as the dimension of the material to shred, the size of the particles, the capacity etc, which affect the selection of the model, the number of the shafts, motors, transmissions, knife specification and so on.

Transport

About Us

FAQ

FAQQ1:How can I choose the suitable machine?

A1: Just tell me what material you will shred, the maximum size of input material, the size of output granular, the work capacity and other information. Then we will give you the suitable solution with good price.

Q2. What material of the blade/knife you can make?

The blade can be made of HSS, H13, 55SiCr, 9CrSi, 6CrW2Si, 42CrMo, SKD-II, D2, DC53, LD, Cr12MoV and other high-performance special steel. Besides, we also supply claw shaft, spacer and chamber, mechanical blade and so on by custom. Q3. How about your after-sale service? We offer you 24 hours online service by phone, Skype or What's app. Q4. Quality Control: The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. Our machines all have passed CE Certificate, meet European and American standard, were exported to more than 100 Countries. Q5. How we pay you? A. Consult us about this product on line or by e-mail. B. Negotiate and confirm the final price, shipment, payment methods and other terms.C. Send you the proforma invoice and confirm your order.D. Make the payment according to the method put on the proforma invoice.E. We prepare for your order in terms of the proforma invoice after confirming your full payment and 100% quality check before shipping.F. Send your order by air or by sea.