LDPE, CPP, CPE Cast Film Machinery

CHINA GTL TOOLS LIMITEDBase Info

Description

Basic Info.

Model NO. SJ-65&SJ-90&SJ-55 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Transport Package According to Customers Needs Specification CE, BV, SGS ISO2008 Trademark WEIER Origin Qingdao, China HS Code 84772090 Production Capacity 10 Sets/MonthProduct Description

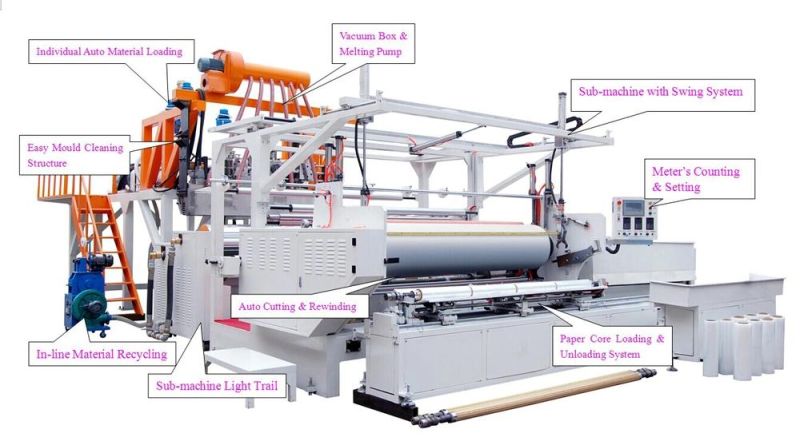

New High quality co-extrusion stretch film /cast film machine

1) Main parts: one electrical power control box, 3 extruder, one die,2 cooling forming rollers,on-line recycling system,auto-cutting system,auto-winding system,2 winding shafts etc.

2) Layers to be produced: Single layer(one side sticky or 2 sides sticky stretch film)

3) Voltage:380V or according customer's requirments

4) Spare parts: All advanced spare parts are imported from Japan,Germany,France brand parts etc.

5) Width to be produced: min500mm to max 1500mm

6) Thickness to be produced: 0.012mm-0.05mm

Outstanding Features of WEIER Stretch Cling Film Machine:

1) Higher output with stable quality stretch film,superior than the same suppliers more than 30%.

2) Higher speed with good ideal tensile and anti-pricking stretch film, which make sure the machine make big output.

3)Good water cooling effect and imported die steel to ensure making even and good ductility stretch film.

4) Swing system installed to adjust the film thickness and evenness.

5) The alloy screw adopts special mixing function and high plasticizing design which combine import static mixer to ensure plasticization is great, color is uniform and increase extrusion capacity greatly.

6) PLC controlled,fully automatic.

The features of this stretch/cling film machine group:

1.The alloy screw adopts special mixing function and high plasticizing design which combine import static mixer to ensure plasticizing is good,color is uniform and increase extrusion capacity greatly.

2.T-die material employs imports top special mould steel. By high precise process and treatment t ensure the long-term use of the T-die and no deformation. Meanwhile insures material extrusion is more smooth and stable.

3.Inside cool roller adopts two-way circulation design and built-inspiral flow way to ensure roller surface temperature is equal.

4.Winding station can move forth and back. Adopts advanced torque motor with four-axis automatic tension control. Both the speed and film width arefreely adjustable.

Advantages:

1. Rationality in design, Flexibility in structure. The machine divides into three parts. That is main part, auxiliary part and independent electric cabinet.

2. What's more, there is an oscillating device to move the auxiliary part towards the T- die, in order to make sure the operation conveniently.

3. Components and parts are use to assembling after inspected strictly to make sure machine running regularly and long life.

4. The unit is Automation with PLC roll-change automatically. Feed material automatically.

5. Save manpower and low energy consumption.

6. We have complete supporting equipment:

1.online waste recycling machine,

2.waste margin film compact with high speed blender

3.stretch film rewinder

4.chiller

7. We can support complete after- sales service. The engineer will go to your company to install the machine and supply operation training course.

Detailed technical data of stretch/cling film machine:

| Model | WEIER-65/90/65*1850 | WEIER-65/90/65*1800 | WEIER-55/80/55*1250 |

| Layers | 3-layers | 3-layers | 3-layers |

| Screw diameter | 65mm/90mm/65mm | 65mm/90mm/65mm | 55mm/80mm/55mm |

| Screw L/D ratio | 32:1 | 32:1 | 32:1 |

| Screw speed | 20-150rpm | 20-150rpm | 20-150rpm |

| Max output | 150-220kg/hr | 120-220kg/hr | 100-180kg/hr |

| Max width | 1500mm | 1500mm | 1000mm |

| Thickness | 0.012-0.05mm | 0.012-0.05mm | 0.012-0.05mm |

| Total power | 150kw | 150kw | 100KW |

| Dimension | 12500*3800*3500mm | 12000*3600*3400mm | 7600*3500*3500mm |

| Weight | 15T | 14T | 11T |