Automatic Fresh Vegetable and Fruit Grading Equipment

AIRMAX AL CO., LIMITED- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Grading machine

- Customized:Customized

Base Info

- Type:Grading Machine

- Material:304stainless Steel

- Motor Brand:ABB,Siemens Optional

- Power(W):200-400W

- Voltage:220V,50Hz

- Grading Rage:5-9grades

- Speed /Min:280-310 No.S

- Weight:200-300kg

- System Function:Records Each Grade Weight & Counts

- Water Proof:IP65

- Weighing System:German Imported (IP69)

- Warranty:1 Years

- Date of Delivery:20-35days

- Worker Needed:2-4 Workers

- After-Sales Service Provided:Field Installation, Commissioning and Training

- Transport Package:Wooden Case

- Specification:(2.5-3.3)*1*2m

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:800-1200kg,H

Description

Basic Info.

Type Grading Machine Material 304stainless Steel Motor Brand ABB/Siemens Optional Power(W) 200-400W Voltage 220V/50Hz Grading Rage 5-9grades Speed /Min 280-310 No.S Weight 200-300kg System Function Records Each Grade Weight & Counts Water Proof IP65 Weighing System German Imported (IP69) Warranty 1 Years Date of Delivery 20-35days Worker Needed 2-4 Workers After-Sales Service Provided Field Installation, Commissioning and Training Transport Package Wooden Case Specification (2.5-3.3)*1*2m Trademark KS Origin Shandong, China HS Code 8438800000 Production Capacity 800-1200kg/HProduct Description

Automatic pitaya apple orange weight grading machine fruit grading equipment

Introduction:

Automatic pitaya apple orange weight grading machine fruit grading equipment is mainly used for weighing round and oval shape materials, such as sea cucumber, avocado, lobster and so on. it is mainly used in a variety of automation production flow lines to select the products by weight in the industry of pharmaceutical, food, aquatic poultry and other industries weight sorting. Material is weighed on production line with high precision and dynamic, and classified accurately by industrial computer. It can directly replace manual weighing in order to improve production efficiency, improve accuracy and reduce labor, reduce labor intensity and realize industrial automation.

Application

It's widely used for grading apples, pears, persimmons, pears, potatoes, onions, oriental melons and so on.

Main features

1. This electronic fruit grader is efficient and precise.

It's widely used for grading apples, pears, persimmons, pears, potatoes, onions, oriental melons and so on.

2. It is controlled by PLC, and is highly intelligent. Weighing, logic calculation, counting are integrated and so on.

3. It is controlled by PLC, and is highly intelligent. Weighing, logic calculation, counting are integrated.

4. The main components use competitive Product imported, they are of high quality, and lower fault rates, longevity of service.

5. The operation and maintenance of the machine is easy and laborsaving. It contains counting and warning device.

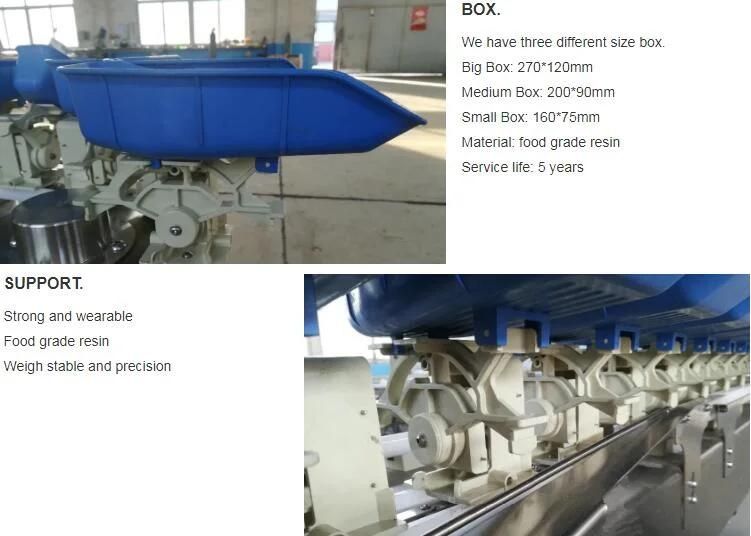

Detailed pictures of fruit grading machine

we have different size of box.

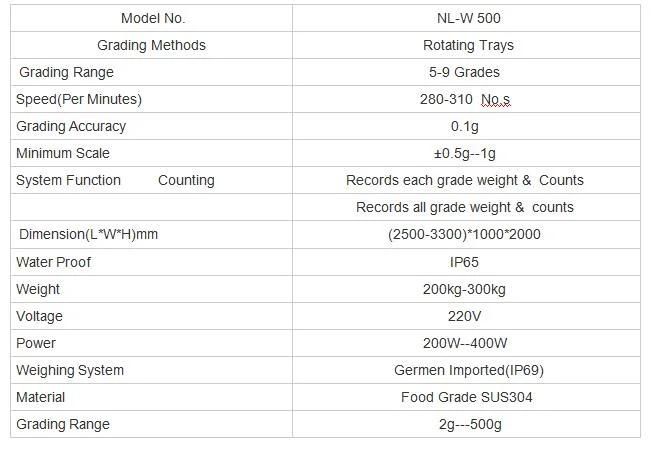

Technical parameter

Fruit processing grading line

This fruit processing grading line consists of fruit conveying and brush washing polishing, waxing, air drying and roller type sorting functions. Our machine can used for all kinds of round or nearly round fruits and vegetables, such as: orange, navel orange, lemon, Hu You, tomato, peach,apple and other vegetables' processing.

1.washing and waxing part

a. for cleaning and waxing fruits, such as apple, citrus, navel orange, honey pomelo et

b. to make the fruit appearance look bright, and improve the fruit price for sale. At the same time,

after waxing, a layer of wax membrane will be coated on the fruit to keep the fruit away from

bacteria and elongate the fruit storage time.

2. Electric Grading part

a.This electronic fruit grader is efficient and precise. It's widely used for grading apples, pears, persimmons,onions,lemons,mangos,pomelo,jujube,and other round fruits.

b.It is controlled by PLC, and is highly intelligent. Weighing, logic calculation, counting are

integrated.

c.Tetrafluoroethylene is covered onto the working surface to keep the machine running stably with low noise and increase the shelf life of the machine. The operation and maintenance of the

machine is easy and laborsaving.

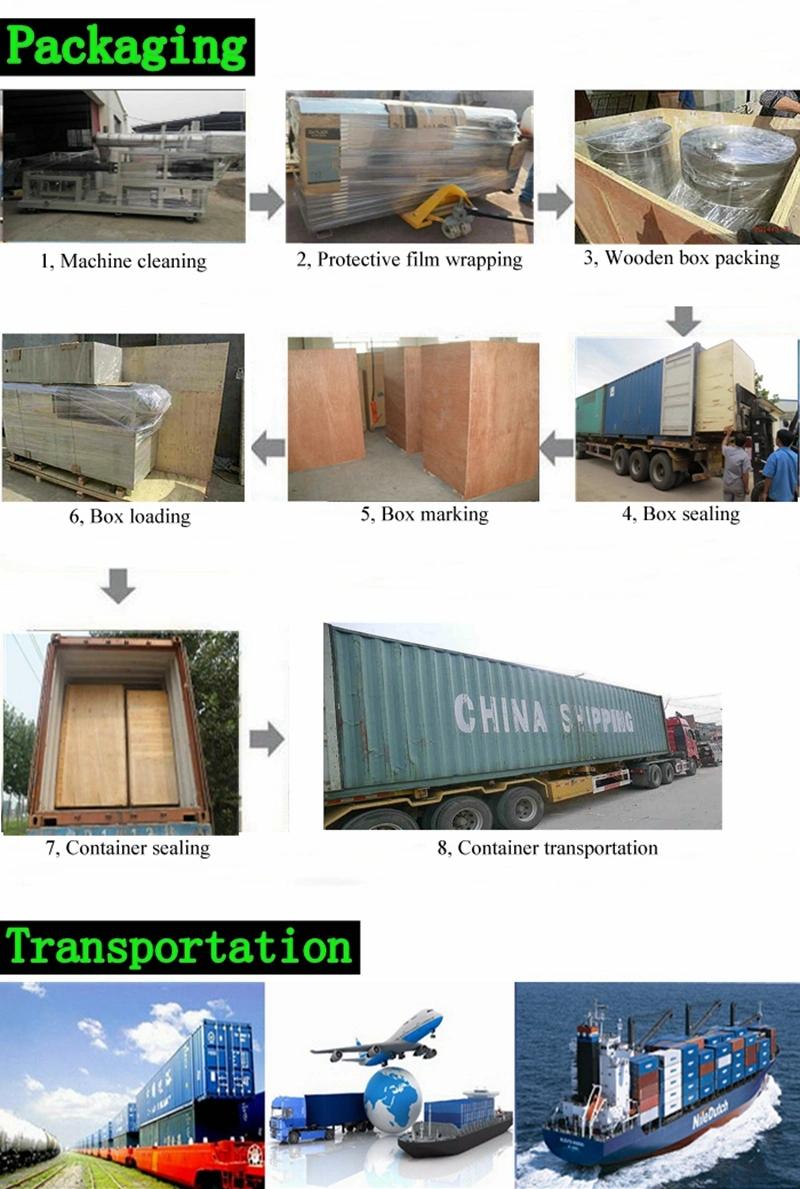

Packaging and shipping:

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottom.With this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

Company Information:

Keysong was founded in 2013. Specializing in producing food machines for more than 6 years. Since its inception, it is specializing in the manufacture, research, development, sales and after-sales of food extrusion machine, puffed food production line, fruit and vegetable washing and drying processing line.

Our History:

In 2013, Keysong was established, concentrating on manufacturing and selling extrusion snack production line at home and abroad.

In 2014, Keysong broke traditional breakfast cereal production technology, and invented new production process.

In 2015, Keysong moved to a new workshop, which covers the area of 5000 square meters. In 2015, we have our agency in India, Nigeria, Thailand, Morocco and Algeria.

In 2016, Keysong cooperated with Shandong Liwei Microwave equipment, started researching on food microwave drying technology. In August, 2016, Keysong build a team, concentrating on researching on the technology of vegetables and fruits washing, cutting, drying and freezing. And has received great results till now.

About us & more details:

| MOQ | 1 set |

| Supply Ability | 20 sets per Month |

| Shipping port | Qingdao port, Shandong, China |

| Packing details | Fumigation-free wooden case outside, stretch film inner |

| Relevant spare parts | free, delivery with processing line |

| Guarantee | Within 12 months |

| Oversea service | Provide installation and commissioning after machine arrived your factory |

| Payment terms | 30% is paid by T/T as the down payment, 70% is paid by T/T or L/C before shipment. |

| Delivery time | 30 days after receipt the deposit |

| Pre-shipment | When it finished, we will invite you to our company to inspect machines, when no problem, we will arrange the shipment |