1200 1400 1600 1800 2000 PP Hollow Board Extruder/PP Board Extrusion Line

Ningbo Easyget Co., Ltd.Base Info

Description

Basic Info.

Model NO. SJ90 100 120150 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Machine Type PP Hollow Board Extruder Production Speed 0.3-6m/Min Raw Material PP Granule with Masterbatch Sheet Thickness 2-5mm or Customerized Application Packing Mold T Type Width 1200 1400 1600 1800 2000mm Delivery Time 60 Days Certification Ce Transport Package Shipping Packing Specification SJ90 100 120 150 Trademark TS Origin China HS Code 8477209000 Production Capacity 100sets/YearProduct Description

1. pp hollow board extruder/PP board extrusion lineThis production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

2. PP hollow board application

a, PP hollow sheet with the same processing properties of cardboard, can be nailed, can be cut, bonded, printable, pressed into a box.

b ,PP hollow sheet has better physical properties than the carton, carton stability than good, not easy to tear, impact resistance is better than the carton, add colorant, cover the composite layer can be made of colorful products.

c, the grid plate with a waterproof, corrosion-resistant, moisture-resistant, insects are not boring, not long fungi, acid and alkali, harmless, pollution-free and other excellent performance.

d, the PP hollow sheet in use can be processed into a similar carton printing appearance, carton hardness than high, long life, good toughness, high strength, energy conservation. Quality products, light, smooth surface

3. model of pp hollow board extruder/PP board extrusion line

| Model | Sheet Width | Sheet Thickness | Extruder Model | Motor Power |

| TS-1400 | 1250mm | 2-6, 8-12mm | 100/36 | 55-75kw |

| TS-1860 | 1700mm | 2-6, 8-12mm | 120/6 | 75-90kw |

| TS-2300 | 2150mm | 2-6, 8-12mm | 120/36 | 90-110kw |

| TS-2600 | 2450mm | 2-6, 8-12mm | 120/36 | 90-110kw |

| TS-3000 | 2800mm | 2-6, 8-12mm | 150/36 | 132kw |

| TS-2600(Co) | 2460mm | 2-6, 8-12mm | 120/36 +80/36 | 110+37kw |

4. machine part of pp hollow board extruder/PP board extrusion line

| No. | Machine name | Quantity |

| 1 | Material mixing machine | 1 set |

| 2 | Single screw extruder | 1 set |

| 3 | Single screw co-extruder | 1 set |

| 4 | Screen changer | 1 set |

| 5 | Co-extruder mold:ABA | 1 set |

| 6 | Calibrating machine | 1 set |

| 7 | Six-pairs haul off machine 1st | 1 set |

| 8 | Preheating Oven | 2 sets |

| 9 | Cooling device | 1 set |

| 10 | Corona treatment device | 1 set |

| 11 | Edge cutting device | 1 set |

| 12 | Three-pairs haul off machine 2nd | 1 set |

| 13 | Transverse cutting machine | 1 set |

| 14 | Stacker | 1 set |

5. details of pp hollow board extruder/PP board extrusion line

a. Extruder for pp hollow board extruder/PP board extrusion line

the co-extrusion system is used for making AB layer PP hollow sheet.

the inner layer can use recycled PP material or High PP filling material.

The specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding.

auto spiral screw feeder

drying hopper

siemens motor

aluminum heater

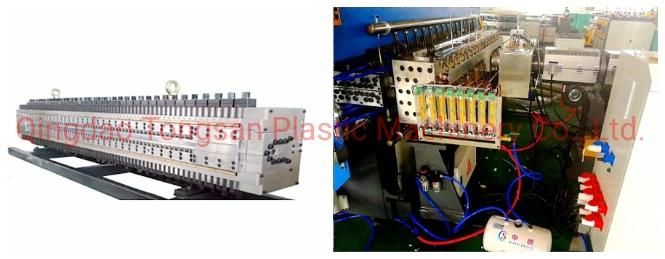

b. Mould for pp hollow board extruder/PP board extrusion line

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

c. calibrating table for pp hollow board extruder/PP board extrusion line

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

d. haul off device for pp hollow board extruder/PP board extrusion line

There are two tractors. The first one is high power, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

e. Heating oven for pp hollow board extruder/PP board extrusion line

the heating oven device is necessary for the PP hollow sheet to remove the stress of the sheet, the heating oven should be made by 304 stainless steel, the heating oven is equipped with separately temperature control system for each zone to ensure the heating to be uniform, 4 meter lengths of heating oven is necessary

f. corona treatment for pp hollow board extruder/PP board extrusion line

The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

g. Auto Cutter for pp hollow board extruder/PP board extrusion line

Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

6. how to make a box ?

How to make PP packing box from the PP hollow corrugated sheet?

PP hollow sheet turnover box main material is a PP hollow sheet, and then after the pressure cut, torn edges, stitching, assembly and made of a series of processing flow.| Item | PP packing box making Machine | Note |

| 01 | Material Mixing machine | For mixing material, such as chemicals, color masterbatch, filling masterbatch, recycle material |

| 02 | PP hollow corrugated sheet extrusion line | For makeing Pp hollow corrugated sheet for required width and thickness.width: 1200-2700mmthickness: 2-12mm |

| 03 | PP hollow sheet die cutting machine | For cutting the Pp sheet into required shape for folding box |

| 04 | PP hollow sheet printing machine | for printing logo and designs on the Packing box, there is different printing machine, such as single color printer, double color printer, four color printer. |

| 05 | PP hollow sheet welding machinePP hollow sheet bookbinding machine | For folding the Pp hollow sheet into required box shape, welding machine and bookbinding machine both can work for |

7. Comparing of canton packing material and PP hollow sheet material

a, Paper - paper fear of water, fear of tide, perishable, can not guarantee the quality of the product transport, there may be increased costs, so most of the cartons, cartons, cardboard and other paper products can only be used once.

b, PP hollow sheet related products can be flexibly produced, compared to the expensive plastic injection box, PP hollow sheet box cheaper many, customized according to customer size, thickness, toughness, hardness, printing, etc.

c, Traditional cartons will be broken after several times of using, the PP hollow sheet crates life is about 20 times of the carton material, or even longer, it can reduce the using cost greatly.

d, And the PP hollow sheet products are non-toxic, pollution-free, environmental protection, waterproof, moisture-proof, shock absorption and other characteristics, compared with traditional cardboard, wood, easy to use, easy to store, can be reused, long life, but also recycling, Higher social and economic value.