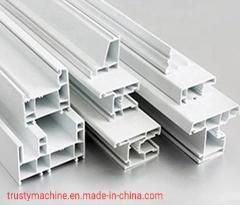

PVC Profile Production Line/Plastic Machine with CE

Ningbo Conwhole Hardware Co., Ltd.Base Info

Description

Basic Info.

Model NO. SJSZ-65/132 Assembly Structure Separate Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Transport Package Wooden Packing Specification Customized Trademark Trusty Origin Qingdao HS Code 84772090 Production Capacity 10sets/MonthProduct Description

1.Production IntroductionPVC/WPC window and door profile production line products can be used to make building templates, boards for toy building blocks, pallets, packing boxes, packaging appliances and other packaging products, bottom auxiliary boards, sleepers and other storage supplies, outdoor flooring, guardrail, garden chairs and other outdoor supplies.

The production line consists of mixer, feeder, twin-screw extruder, extruding mould, customized mould,calibration table, haul-off, cutter,stacker, crusher and mill.Wood plastic products can resist strong acid and alkali, water and corrosion.It doesn't breed bacteria. It's not easy to be moth-eaten and produce fungus.And it also can prevent aging, static electricity, and burning.

2.Machine List

2.Machine List| Name | Quantity(set) |

| Mixer300/600 | 1 |

| Feeder | 1 |

| Twin screw extruder | 1 |

| Extruding mould | 1 |

| Customized mould | 1 |

| Calibration table | 1 |

| Haul off | 1 |

| Cutter | 1 |

| Stacker | 1 |

| Crusher | 1 |

| Mill | 1 |

3.Technical Parameters

| Model | SJSZ-65/132 |

| Total installation power(kw) | 130 |

| Transformer (kw) | 100 |

| Actual electricity consumption(kw) | 50 |

| Output (kgh) | 180-240 |

| Line speed (mmin) | 0-4 |

SJSZ-65/132 Extruder

Work flow and detailed information:

Work flow and detailed information: | Feeder | • To feed material into extruder; |

| Extruder | •World famous brand electrical component: Siemens, Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

| Die head | • 3Cr13/3Cr17 material • Complete set include extrusion die head, calibrator and cooling tank |

| Calibration table | • Include full set of vacuum and water pump • Width: 240mm • Length: 6000mm • Independent operation panel for easy operation |

| Haul off | • Upper/lower caterpillar driven separately and speed control by inverter • Fast change type pads for easy operation |

| Cutter | • Lifting saw cutter with adopts double station dust collection system •Synchronous driving by air cylinder or servo motor control |

| Stacker | • Stainless steel304 as touching material • Discharge driving by air cylinder |

4.Production Process

Mix the material→Feed→Extrude→Customize→Haul off→Cut→Stack the material →Crush→Mill

5.Company Profile Qingdao Trusty Plastic Machinery Company is a professional company specialize in designing and manufacturing plastic extrusion machine. We introduced and absorbed the advanced plastic processing technology, which can provide the technology and machinery one-step service.

Our machines are exported to more than 20 countries which are located in Europe, Middle East, Africa, South America, Southeast Asia, Russia and other places. and we will also provide the thoughtful after sales service.

6.After sales service

(1)After the machines are finished, the seller will test all machines before shipment. If the buyer can not come to test the machine, we will test the machines and send the sample to buyer.

(2)After shipment, the seller will send one or two technicians to the buyer' s factory to help the buyer install the machine and train workers for buyer.

(3)We will supply all electricity drawing, machine installation drawing.

(4)When make shipment, we will put some spare electricity parts for free, like the barrel hearers, thermcouples, breakers, relays, and other items which is easier broken.