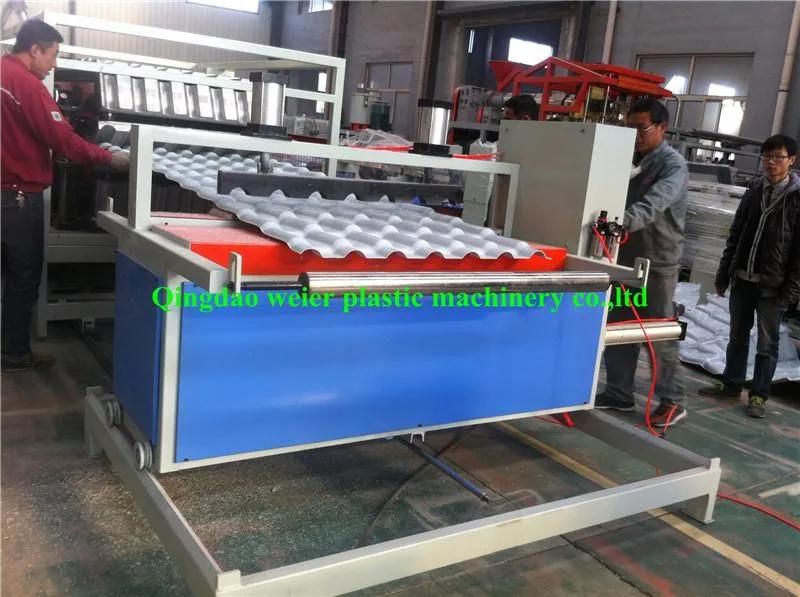

880mm UPVC and Asa or PMMA Co-Extrusion Bamboo Roof Tile Extrusion Line

CHINA GTL TOOLS LIMITEDBase Info

Description

Basic Info.

Model NO. SJSZ-80/156 and SJ-45/30 Roof Tile Width 880mm Roof Tile Thickness 3-4mm Capacity 250-400kg/Hr Center Height 1000mm Line Speed 0.3-2m/Min Daily Output 1000m2/24hrs Cooling Water ~3t/H Compressed Air 0.3m3/Min, >0.5mpa Total Power 157kw Transport Package Machine Covered by PE Film; Mould in Wooden Case Specification As per customer′s request Trademark Weier Origin Qingdao City, Shandong Province, China HS Code 84772090 Production Capacity 100sets/YearProduct Description

880mm UPVC and Asa or PMMA Co-Extrusion Bamboo Roof Tile Extrusion Line

Features of PVC+PMMA/ASA glaze roof tile production linePlastic glazed tile extrusion line consists of extruder, T die and shaping downstream units, which can continuous extruding single layer PVC glazed tile, PVC/PMMA and PVC/ASA composite multi-layer glazed tile.

The extrusion line is mechantronics, with the advantages of: High production efficiency, reasonable structure, convenient operation and maintenance, long use life etc.

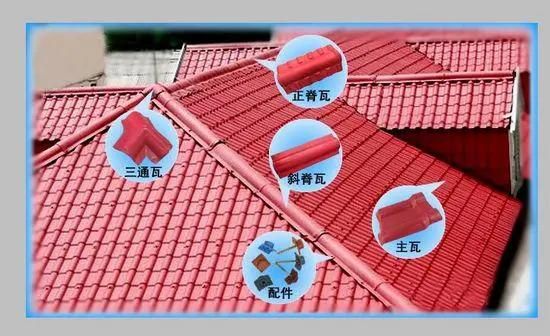

Compared with ordinary plastic tile, glazed tile has more beautiful appearance, better quality, strong durability and some special features, such as anti-fire, anti-corrion, anti-freeze, good weather resistance and color retention, etc.

The glazed tiles are widely used in the garden-style factory, tourist scenic spots, pavilions, hotels, family building etc.

Applications:The Plastic Roofing Tile Roll Forming Machine is mainly used in the production of plastic glazed tile. The plastic glazed tiles are widely used in the garden-style factory, tourist scenic spots, pavilions, hotels, family building, etc.

Glazed tile product features:

1. Excellence weather fastness;

2. Waterproof outstanding performance;

3. Wind resistance, quake-proof;

4. Rich color, new personalized, stable and lasting;

5. Excellent fireproof performance;

6. Heat insulation, heat preservation;

7. Good sound insulation performance;

8. Excellent toughness and strength;

9. Simple construction--paving speed most quickly, construction cost minimum;

10. Economical.

Raw material & formulation | PVC resin, Caco3, lubricant, stabilizing agent, pigment, anti-ultraviolet agent, Pigment etc |

Central height: | 1000mm |

Max. Haul-off speed: | 0.3-4m /min |

Operation direction | From right to left (face to the operation panel) |

Machine color | Blue or as per your request |

Description final product & Output capacity | Single layers UPVC Roofing tile; Width:880 or 1050mm,Thickness: 2 ~4.0mm; Wave distance:180mm; Wave height:30mm; Output:200-350kg/h(Depending on CaCO3 proportion) |