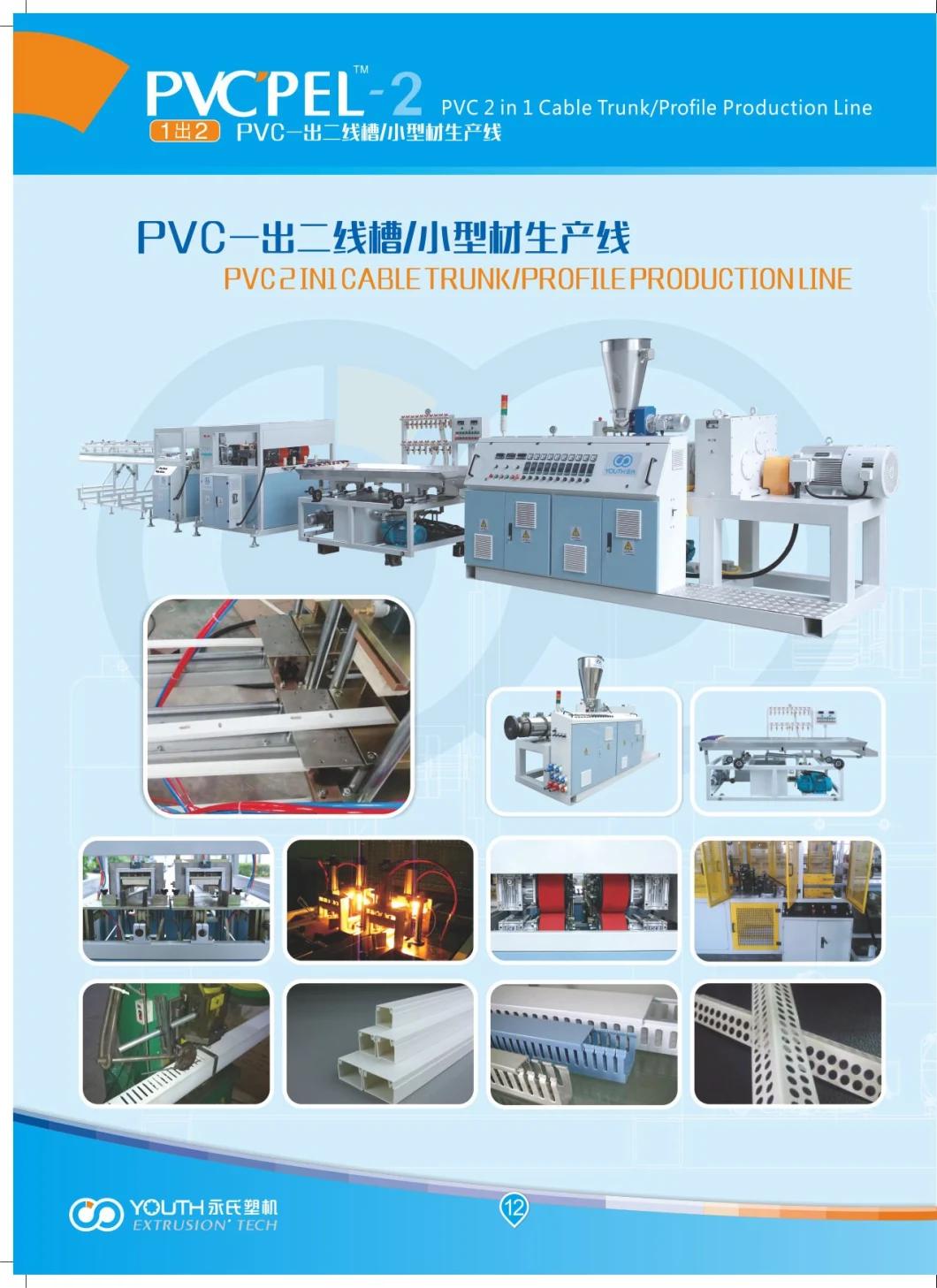

PVC Cable Trunking Extrusion Machine PVC Cable Tray Duct Making Machine

Ningbo Rena International Trade Co., Ltd.Base Info

Description

Basic Info.

Model NO. SJ55 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Cutting Type Dust Free-Heat Cutting Cavities 4 Cavities/2cavities/Single Cavity Output Max.250kg/H Sinlge Line Speed 3-22m/Min Transport Package Wood Specification 20mx1.5mx2m Trademark YOUTH Origin China Production Capacity 1000set/YearProduct Description

PVC Cable Trunking Extrusion Machine PVC Cable Tray Duct Making Machine

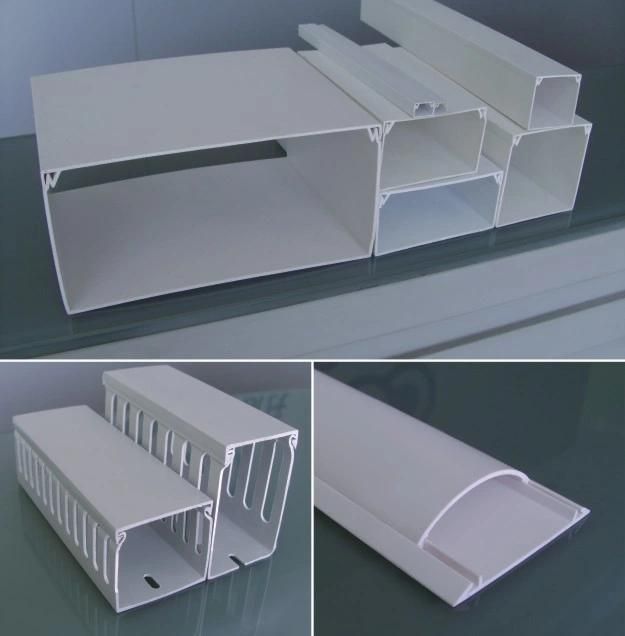

PVC cable trunking machine ( 4 in 1) is made of a 65/132 conical twin screw extruder, one set of 4 in 1 mould, one set of calibration table , haul-off & cutting combination (dust free) and stacker.The diameter of the best production tube is within 40*30mm.Main features: high capacity, low power consumption, low water gas consumption, low occupation, low noise, low dust, etc. 4 in 1 products can be produced at one time.

PVC cable trunking machine ( 2 in 1) is made of extruder, one set of 2 in 1 mould, one set of calibration table , haul-off & cutting combination (dust free) and stacker.The diameter of the best production tube is within 60*40mm.Main features: high capacity, low power consumption, low water gas consumption, low occupation, low noise, low dust, etc. 2 in 1 cable trunking products can be produced at one time.

PVC cable trunking machine ( 1 in 1) is made of extruder, one set of 1 in 1 mould, one set of calibration table , haul-off & cutting combination (dust free) and stacker.The diameter of the best production tube can be up to 200*100mm.Main features: high capacity, low power consumption, low water gas consumption, low occupation, low noise, low dust, etc.

| NO. | name | |

| 1 | extruder | |

| 2 | 4in1 cable trunk mold | |

| 3 | calibration table | |

| 4 | 4 in 1 haul-off | |

| 5 | 4 in 1 cutter | |

| 6 | stacker | |

| 7 | feeder |