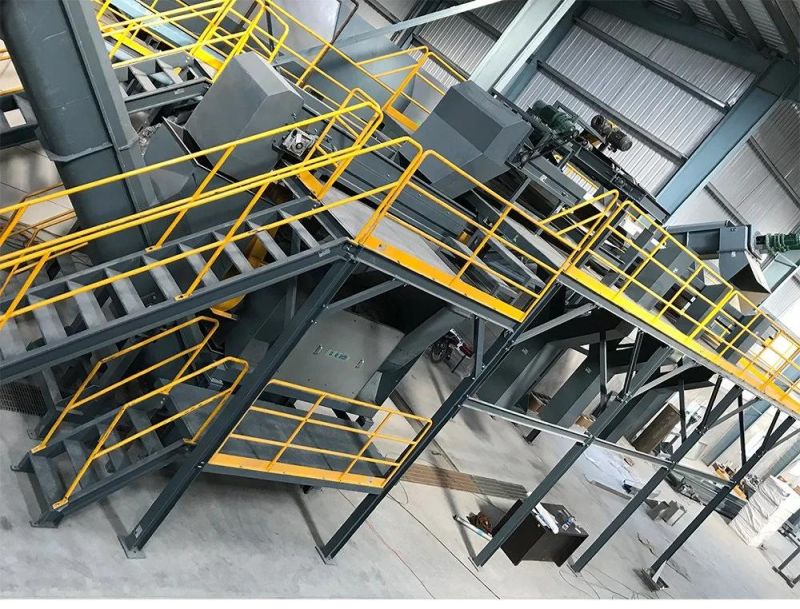

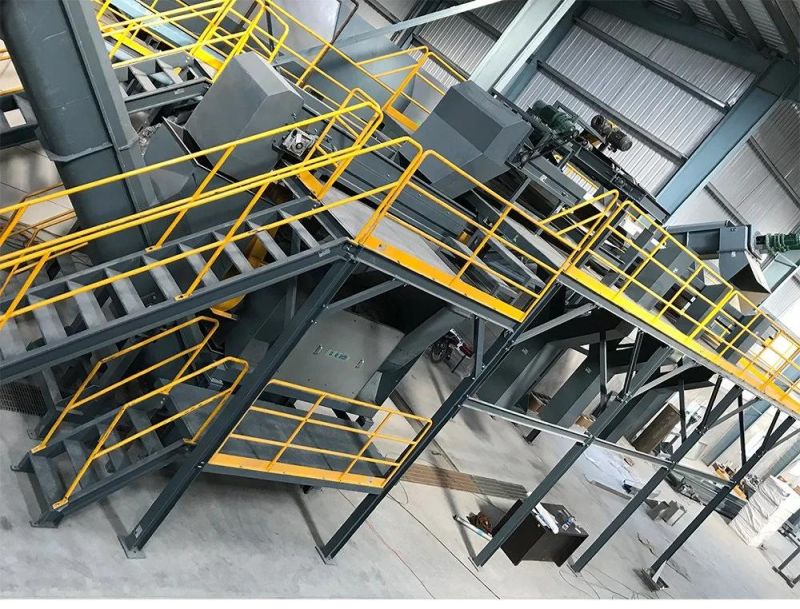

1500kg/H PET Bottle Washing System

Zhecheng Hongxiang Superhard Material Co., Ltd.Base Info

Description

Estimated Plant Parameters Input Capacity

(kg/h) Required Area

(m2) Installed Power

(Kw) Required Water

(kg/h) Required Steam

(kg/h) Requied Compressed Air(m3/min) Manpower 1500 1500 600 2.25 700 3.5 5 3000 2000 900 4.5 1300 6.5 7 6000 3000 1000 9 2300 12 11 9000 4500 1600 14 3200 20 16 Capacity

(kg/h) Electricity Consumption

(KWh) Steam

(kg) Washing Detergent

(kg) Water Consumption

(ton) 1500 170 550 12 1.5 3000 160 500 12 1.5 6000 150 450 12 1.5 9000 145 400 10 1.5 Input Capacity

(kg/h) Required Area

(m2) Installed Power

(Kw) Required Water

(kg/h) Required Steam

(kg/h) Requied Compressed Air(m3/min) Manpower 500 800 170 0.75 200 0.5 8 1500 1200 400 2.25 700 0.5 12 3000 1800 600 4.5 1300 0.7 18 6000 2800 900 9 2300 1 30 9000 4200 1400 14 3200 1.5 40 Input

Capacity

(kg/h) Electricity Consumption

(KWh) Steam

(kg) Washing Detergent

(kg) Water Consumption

(ton) 500 140 550 6 1.5 1500 130 500 8 1.5 3000 120 450 8 1.5 6000 100 400 8 1.5 9000 95 350 8 1.5

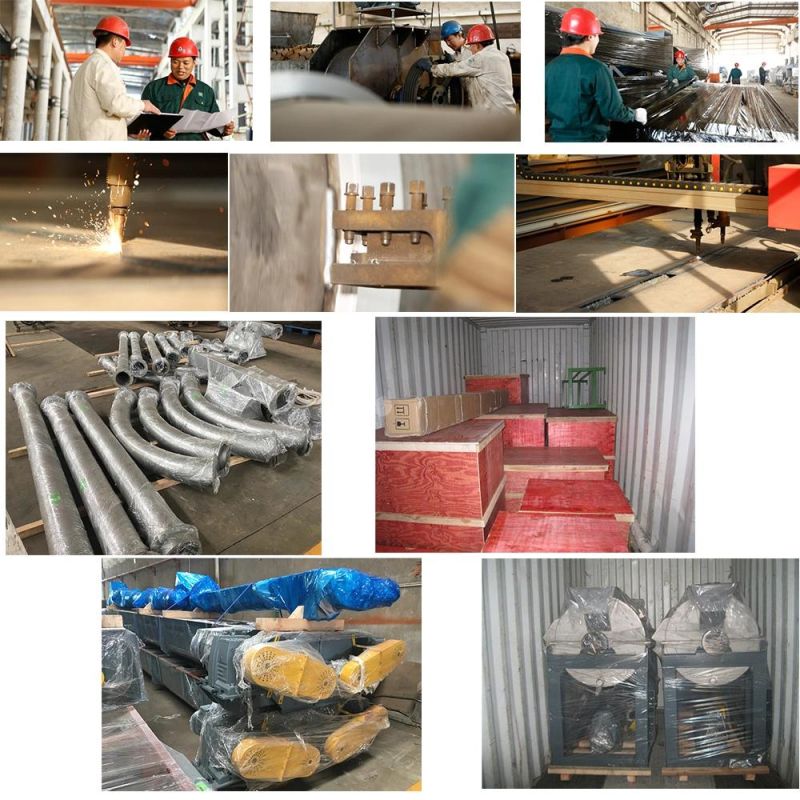

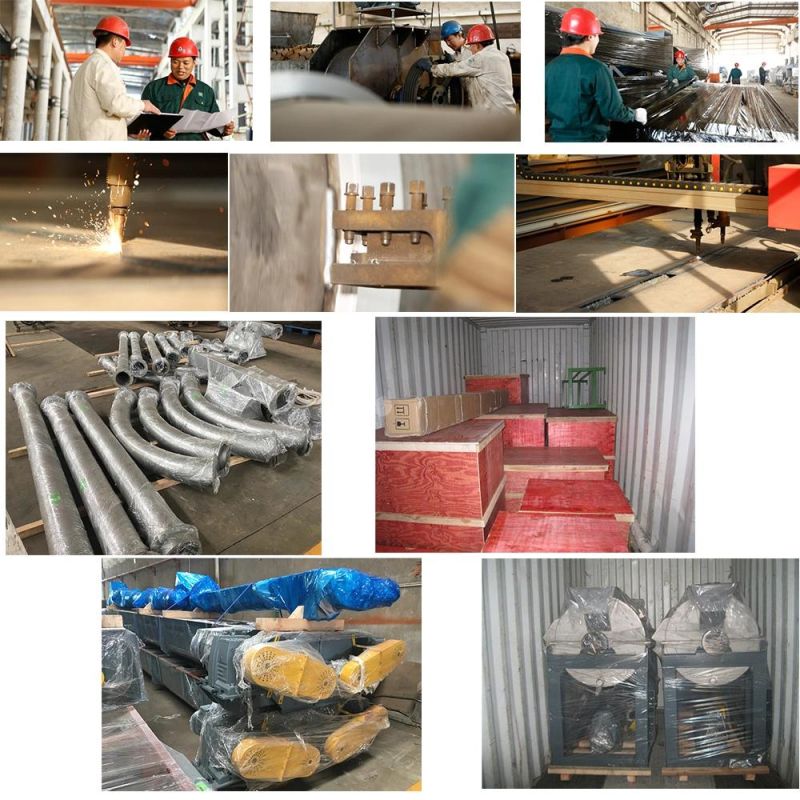

Our service1,pre-sale support:Normally we suggest you paint our standard color , but we can supply customization paint service by paid.2,after-sale service:Warranty:1 year for machinery,6 months for electrical.

For mechanical parts, our guarantee duration is 12 months. If the part is broken within this period, we will send the spare parts immediately to the client for repairing.

3,technical support:

Normally, we send our engineer(s) to supervise the installation and commissioning. The buyer need to prepare the operation staff to implement it. BORETECH is able to send mechanical engineer, electrical engineer and operation engineer. The operation engineer is to help the buyer's labors to know how to operate the washing line and get the best efficiency.

Boretech Brief

Boretech is one of the major supplier of PET bottle recycling system in Asia . We uses the around 30 years of fiber making and bottle recycling experiences to manufacture PET Bottle recycling machine and configure Pelletizing line, Polyester Staple Fiber line, POY line and Bottle to Bottle Line. At present, we have supplied about 170 sets plant for more than 30 countries.Our customers in the US, Japan, EU manufacture food grade rPET resin for such well-known brand owner's such as Coca Cola, Niagara Bottling, Nestle, etc.

Boretech can help our customers to make right configuration of the machinery, and find the right position in the industries. The most important value is that we can help our customers to minimize the learning cost and to avoid making any mistake during investment.

(kg/h)

(m2)

(Kw)

(kg/h)

(kg/h)

(kg/h)

(KWh)

(kg)

(kg)

(ton)

- The above parameters are calculated based on the standard contiguartion;PET bottle material composition and factory management level will affect actual consumption.

- Water consumption parameters are calculated based on using wastewater reuse system.

(kg/h)

(m2)

(Kw)

(kg/h)

(kg/h)

Capacity

(kg/h)

(KWh)

(kg)

(kg)

(ton)

- The above parameters are calculated based on the standard contiguartion;PET bottle material composition and factory management level will affect actual consumption.

- Water consumption parameters are calculated based on using wastewater reuse system.

Our service1,pre-sale support:Normally we suggest you paint our standard color , but we can supply customization paint service by paid.2,after-sale service:Warranty:1 year for machinery,6 months for electrical.

For mechanical parts, our guarantee duration is 12 months. If the part is broken within this period, we will send the spare parts immediately to the client for repairing.

3,technical support:

Normally, we send our engineer(s) to supervise the installation and commissioning. The buyer need to prepare the operation staff to implement it. BORETECH is able to send mechanical engineer, electrical engineer and operation engineer. The operation engineer is to help the buyer's labors to know how to operate the washing line and get the best efficiency.

Boretech Brief

Boretech is one of the major supplier of PET bottle recycling system in Asia . We uses the around 30 years of fiber making and bottle recycling experiences to manufacture PET Bottle recycling machine and configure Pelletizing line, Polyester Staple Fiber line, POY line and Bottle to Bottle Line. At present, we have supplied about 170 sets plant for more than 30 countries.Our customers in the US, Japan, EU manufacture food grade rPET resin for such well-known brand owner's such as Coca Cola, Niagara Bottling, Nestle, etc.

Boretech can help our customers to make right configuration of the machinery, and find the right position in the industries. The most important value is that we can help our customers to minimize the learning cost and to avoid making any mistake during investment.