Hot Sale Red Chili Stem Cutter

Jiangyin Yiran International Trading Co., Ltd.- Type:Cutter

- Voltage:380V

- Power:0.75KW

- Customized:Customized

- Transport Package:Wood

- Specification:0.6

Base Info

- Trademark:genyond

- Origin:China

- Production Capacity:50000

Description

Basic Info.

Trademark genyond Origin China Production Capacity 50000Product Description

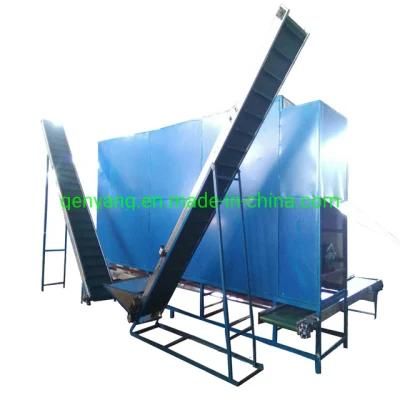

CHILI STEM CUTTER

| Model | Capacity | Power | Voltage | Speed | Weight | Dimension | Material |

| 50-2S | Fresh chili 250kg/h Dry chili 120kg/h | 3KW | 220V | 1400RPM | 238kg | 2.86×0.59×1.36m | Stainless steel |

| 50-2A | Fresh chili 250kg/h Dry chili 120kg/h | 3KW | 220V | 1400RPM | 238kg | 2.86×0.59×1.36m | Carbon steel |

| 50-2SLT | Fresh chili 330kg/h Dry chili 180kg/h | 3KW | 220V | 1400RPM | 357kg | 3.86×0.59×1.36 | Stainless steel |

| 50-2ALT | Fresh chili 330kg/h Dry chili 180kg/h | 3KW | 220V | 1400RPM | 357kg | 3.86×0.59×1.36 | Carbon steel |

| 50-2SBIGS | Fresh chili 500kg/h Dry chili 250kg/h | 4.4KW | 220V | 1400RPM | 470kg | 2.86×1.5×1.1 | Stainless steel |

| 50-2ABIGS | Fresh chili 500kg/h Dry chili 250kg/h | 4.4KW | 220V | 1400RPM | 470kg | 2.86×1.5×1.1 | Carbon steel |

| 70W-2ANF | Fresh chili 700kg/h Dry chili 350kg/h | 4.4KW | 220V | 1400RPM | 450kg | 4.86×0.68×1.65 | Stainless steel |

| 70W-2ATL | Fresh chili 700kg/h Dry chili 350kg/h | 4.4KW | 220V | 1400RPM | 450kg | 4.86×0.68×1.65 | Carbon steel |

This chilli stem cutting machine is used for cutting the fresh and dried chilli's stem.It can cut many types chilli.please refer to specification form.

1,the equipment suddenly stop when it is working

why the equipment stop suddenly?

Maybe something stop it. such as iron wire,nails,stone enter the machine stop the mesh;

Maybe you put the chili too much and too fast, the-feed to jam already, please put chili as the machine's model, put the chili uniform, put the chili little by little;

Maybe the extension spring is too tight;

Maybe the motor belt is too tight.

Solution steps:

A. please turn off the electric power.

B. check the mesh and knives. Iron wire ,nails ,stone etc sharp tings stuck them or not. If the mesh had been stuck by the sharp things, fine it out and take it out please.

C. check the extension spring. If you fine the extension spring is too tight, please adjust extension spring, let them looser.

D. check the motor belt too tight or not. If you fine it is too tight, please move the motor let the motor belt more looser.

E. check the motor can work or not. take the motor belt out, the start the motor, if the motor can't work, it show you the motor had broken, buy a new motor replace it.

F. check the reducer have oil or not. if the oil have after use, buy some oil and add the oil into the reducer.

2,one/some mesh is working but another/other off work

Solution steps:

A. please turn off the electric power.

B. check the AC contactor if the electric wire contact well in a good working order or not.

C. if the electric wire contact well but the problem still can't solve, please reference the circuit diagram in last page.

as: the electric wire contact at 1L1 and 5L3 ,2T1 and 6T3.

please change them, move 1L1 line to 3L2 ,move 5L3 line to 13NO,move 2T1 line to 4T2,move 6T3 line to 14NO.

as: the electric wire contact at 3L2 and 13NO ,4T2 and 14NO.

please change them, move 3L2 line to 1L1 ,move 13NO line to 5L3,move 4T2 line to 2T1,move 14NO line to 6T3.

D. start the equipment.