Base Info

Description

Thickness can be settled by customer's requirement2 1372mm 17mm 3 1155mm 15mm 4 1054mm 14mm 5 960mm 14mm

Condition:

Material: HDPE

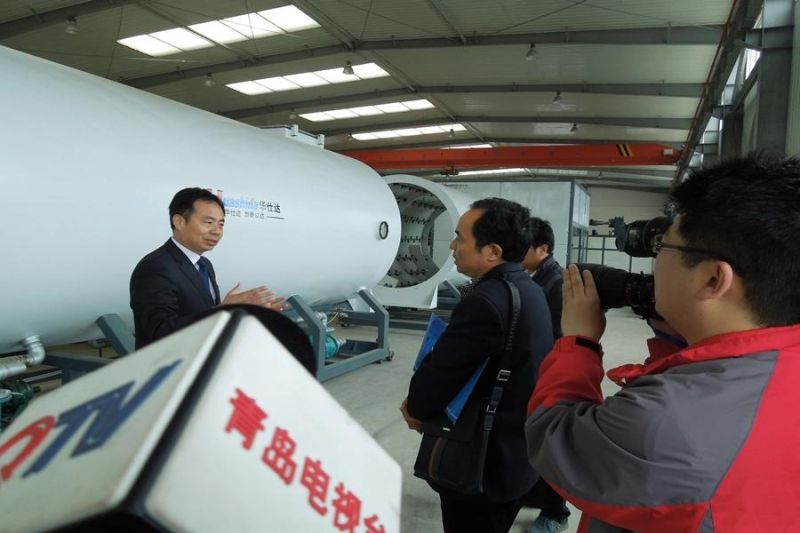

PE-960/1680

PE-960/1680 Pre-insulating Jacket Pipe Production line Configuration

Condition:

- In room

- No danger zone

- 85% no condensation

- Tempreture: 0-35ºC

- 3 phrase ,380V(-10%,+5%)50Hz

- supply: 3 phase 380V(-10%,+5%) 50HZ

- 560 kW

- About 1500KW

- ≤20ºC≥0.3Mpa 26~30 m3/h

- water recycling: ≤20ºC≥0.3Mpa 26~30 m3/h

- air 0.4m3/min >0.5MPa

Total length: About 45m

Material: HDPE

PE-960/1680

PE-960/1680 Pre-insulating Jacket Pipe Production line Configuration

No. | Equipment | Nos |

| 1 | Automatic feeding dryer | 1 set |

| 2 | SJ-150/33 single screw high efficiency extruder | 1 set |

| 3 | Die head and extruder connector | 1 set |

| 4 | Mould 960mm, 1054mm,1155mm,1370mm,1680mm | 1 set |

| 5 | 1680mm die head adjust device | 1 set |

| 6 | 1680 vacuum calibrating tank | 1 set |

| 7 | 1680 cooling tank | 1 set |

| 8 | 12 caterpillars hauling off machine | 1 set |

| 9 | 1680 planet cutting machine | 1 set |

| 10 | PLC computer centralized control system(SIEMENS) | 1 set |

| 11 | Pipe bracket | 1 set |