-

Plastic Extruder Machine Sale Twin Screw Barrel

Standard Barrel Parameter Table (selection table)ModelSize(mm) W*H*LHole Diameter(mm)Center Distance(mm)TD-20115*105*132Φ2318.4TD-30135*115*120Φ30.626TD-35140*120*140Φ3630TD-36160*140*150Φ3630TD-40175*145*160Φ41.634.5TD-50190*150*190Φ5142TD-52200*155*210Φ5243TD-53210*160

-

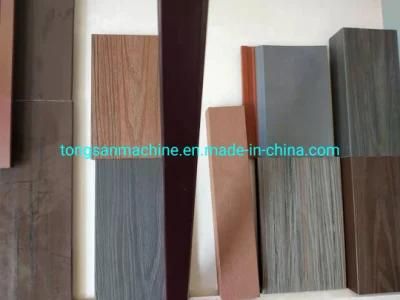

Parallel 135 175 Series Spc WPC PVC Flooring Tile Machine

Capacity:300-400kgs/hAfter sales service during pandemic:Our engineer can still go to your factory to guide machine installation and operator training if entering your country is allowed.FAQQ1---Where is your factory located?---Our factory is located in Qingdao City, Shandong ProvinceQ2---How many e

-

Plastic Lumber Machine Wood Plastic Composite Profiles Making Extruder Production Line

AmericaChileColombiaDominicaEcuadorMexicoPeruUruguayVenezuelaOur advantageA.22yearsmanufacturer for plasticextrudermachines,B.50professionalengineerC,5Q Strictqualitycontrol with CED.20+yearsProfessionalForeignTradeServiceE,Free machine runningF,Turnkey project serviceQuality is Our CultureSince 199

-

Tongsan Plastic Box Machine PP Hollow Corrugated Sheet Extrusion Production Line

AmericaChileColombiaDominicaEcuadorMexicoPeruUruguayVenezuelaFAQ1. Why choose usWe are the first manufacturer in Qingdao to develop plastic extruders. We have 22 years of experience in mechanical manufacturing. What we pursue is machine quality and customer satisfaction.We only choose qualified supp

-

PVC WPC Wood Plastic Composite Foam Board Making Machine

Capacity:300-400kgs/hAfter sales service during pandemic:Our engineer can still go to your factory to guide machine installation and operator training if entering your country is allowed.FAQQ1---Where is your factory located?---Our factory is located in Qingdao City, Shandong ProvinceQ2---How many e

-

PE WPC Co-Extrusion Outdoor Decking Making Machine Production Line Manufacturer

raw material--mixing--granulation--extrusion and molding--surface treatmentMachine ImagesHGMSE series PP/PE WPC profileproduction line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process.The granulating machine make WPC pellets using PP/PE recycled materia

-

PP PE Polypropylene Hollow Corrugated Sheet Board Production Line/Plastic Fluted Grid ...

Model Sheet width Sheet thickness Extruder model Motor powder TS-14001250mm2-6,8-12mm100/3655-75kwTS-18601700mm2-6,8-12mm120/3675-90kwTS-23002150mm2-6,8-12mm120/3690-110kwTS-26002450mm2-6,8-12mm120/3690-110kwTS-30002800mm2-6,8-12mm150/36132kwTS-2600(F)2450mm2-6,8-12mm120/36&80/36110+37kw1,Extrud

-

PP PE WPC Wood Plastic Composite Hollow Solid Decking Flooring Production Line

raw material--mixing--granulation--extrusion and molding--surface treatmentThe production process of WPC profile as follows:(1)PP PE waste plastic crushing and cleaning machine.To recycle waste PP/PE plastic to flakes.Capacity:500kg/h(2)PP./PE WPC granulating machine to make WPC pelletsAfter get rea