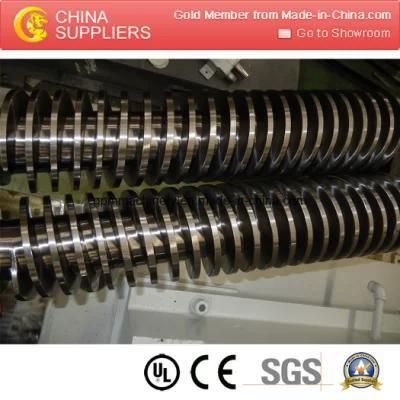

Best Selling Parallel Twin Screw Extruder

Linyi Kunhong Tools Co., Ltd.Base Info

Description

SPECIFICATIONS FOR Conical Twin-screw ExtruderExtruder model Max.output

(kg/h) Total power(kw) GSZ45/100 40-80 15/18.5 GSZ51/105 80-110 18.5/22 GSZ55/110 120-150 22/30 GSZ65/132 280-350 37/45 GSZ80/156 380-450 55/75 GSZ80/173 500-650 75 GSZ92/188 700-850 110/132 GSZ95/196 1000 132/160 Model Motor(KW) Screw diameter(mm) Max.speed(rpm) L/D Max Capacity

(kg/h) Weight

(kg) GSP75/28 37 75 36 28:1 280 4100 GSP93/31 45/55 93 45 31:1 450 4700 GSP110/31 90/110 110 45 31:1 680 6500 GSP120/31 110/132 120 45 31:1 850 7500 GSP135/31 160 135 45 31:1 1100 840

Main Features of china plastic twin screw extruders:

Twin-screw extruder/conical twin-screw extruder/parallel twin-screw extruder

1)Bimetal screw and barrel, nitrided and polished, chromium plated, special treatment.

2) Parallel twin-screw feeder, powerful and high efficiency.

3) Vertical integrated gearbox, more powerful and more stable.

4) High output, can be 40-1100k/h

5) Various of models for choosing, suitable for making different products.

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He

(kg/h)

(kg/h)

(kg)

Main Features of china plastic twin screw extruders:

Twin-screw extruder/conical twin-screw extruder/parallel twin-screw extruder

1)Bimetal screw and barrel, nitrided and polished, chromium plated, special treatment.

2) Parallel twin-screw feeder, powerful and high efficiency.

3) Vertical integrated gearbox, more powerful and more stable.

4) High output, can be 40-1100k/h

5) Various of models for choosing, suitable for making different products.

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He