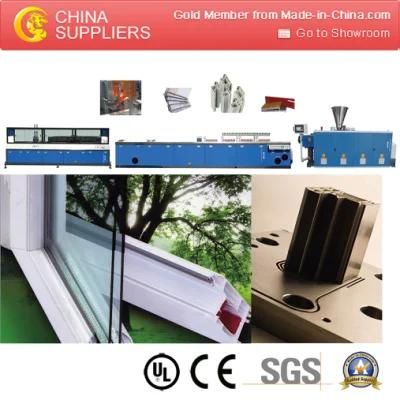

UPVC Window and Door Profile Extrusion Production Line

Linyi Kunhong Tools Co., Ltd.Base Info

Description

Conical twin-crew extruder technical specification for PVC Profile for Window Extrusion LineModel Screw Diameter(mm) Main Moter(kw) Output Capacity(kg/h) GSZ-45 45/100 15/18.5 60/80 GSZ-51 51/105 18.5/22 80/110 GSZ-55 55/110 22/30 120/150 GSZ-65 65/132 37/45 280/350 GSZ-80 80/156 55/77 380/450 GSZ-80A 80/173 75 500/650 GSZ-92 92/188 110/132 700/850 GSZ-95 95/196 132/160 1000

Downstream line technical specification Model Max.product width(mm) Total power(kw) Water Cooling(m³/h) GYF110 110 16 4 GYF240 240 21-32 7 GYF300 300 21-32 7 GYF400 400 21-32 7

Special configuration:

1. GearBox

High efficiency single screw extruder , high output.

2.Feeding mechanism

Parallel twin-screw feeder, suitable for the feeding of powder and mixture .

3.Haul-off

New-designed haul-off structure , strengthen the design of torque .

4.No-dust Cutter

High precision cutting, no dust and low noise.

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13817556740

Jeremy He

Special configuration:

1. GearBox

High efficiency single screw extruder , high output.

2.Feeding mechanism

Parallel twin-screw feeder, suitable for the feeding of powder and mixture .

3.Haul-off

New-designed haul-off structure , strengthen the design of torque .

4.No-dust Cutter

High precision cutting, no dust and low noise.

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13817556740

Jeremy He