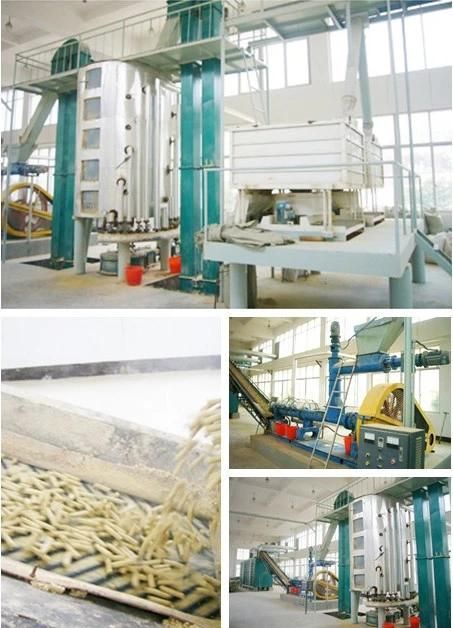

Most Advanced Rice Oil Solvent Extraction Refining and Defatting Line

Shenzhen Xiangfeizhu Technology Co., Ltd.- Type:Rice Mill

- Voltage:220V

- Appearance:Vertical

- Press Materials:Rice

- Press Series:Second

- Condition:New

Base Info

- Model NO.:Huatai-Rice

- Customized:Customized

- Capacity:30tpd-1000tpd

- Transport Package:Bulk

- Specification:Customized

- Trademark:no

- Origin:China

- HS Code:84792000

- Production Capacity:10 Set Per Year

Description

Basic Info.

Model NO. Huatai-Rice Customized Customized Capacity 30tpd-1000tpd Transport Package Bulk Specification Customized Trademark no Origin China HS Code 84792000 Production Capacity 10 Set Per YearProduct Description

Oil extracted from layer between the white rice and the paddy husk is known as rice bran oil. It is an edible oil used as an excipient in food, cosmetics, and pharmaceutical industry. Rice bran oil is preferred by most of the consumers, owing to its antioxidant and low cholesterol property.

Process introduction of pretreatment plant

Crude rice bran -cleaning -softening -expansion -drying -to extraction plant

Extraction section

Extrudedcakes - Extraction - Wet meal toast-desolventizing -Finished meal

Miscella-Evaporation-Stripping -Crude Oil

Process introduction of refining plant

Crude oil-Dephosphorization, degumming, drying and decolorization-Deacidification and deodorization- Dewaxing- Finshed oil- Filling

Advantages of the project

Full continuous and mechanized operations.

Adopting automatic electricity cabinet control.

Electrical engineering implement and match products according to explosion-proof requirements, workshop with separate control room, central control, and the control console to ensure full understanding and control of production conditions in the operation of the equipment.

Circulating pump, cooling towers, solvent pump, power distribution of oil pump, control and workshop inside the restricted area are taken into account.

In order to ensure that plant health and beauty, equipment (according to user requirements) insulation.

Finished Rice bran oil quality index

| Item | Quality index |

| Refined oil color(Lovibond cuvettes133.4mm) | Y30,R 3.0 |

| Smell,taste | No smell,good taste |

| Transparency | Clear and transparent |

| Moisture and volatile matter(%) | ≤0.05 |

| Insoluble impurities (%) | ≤0.05 |

| Acid value (mg KOH/g) | ≤0.2 |

| peroxide value m mol/kg) | ≤5.0 |

| Smoke point(ºC) | ≥215 |

| Freezing test(store for 5.5h at 0ºC) | Clear and transparent |

| Residual solvent (mg/kg) | No |

Company Information

Our company was estabished in 1950s ,now is one of the big oil equipment supplier in China .We have our own R&D department and installation service team with rich experience .

We have successfully obtained 27 national patents (7 invention patents), 6 international medals, 2 state awards, 2 provincial prizes Our machines sell well in more than 30 provinces, and exported to Egypt, Sudan, Tanzania, Rwanda,Nigeria,Estonia,Russia,Kazakhstan,Uzbekistan,Tajikistan,Bangladesh,Thailand,Malaysia,Indonesia, Bolivia,Peru and so on.Now we have developed into a major oil machinery manufacture base in China.

Our main project scope include

--10~5000TPD oilseed pretreatment project

--20~5000TPD solvent extraction project

--10~500TPD oil refining project

--10~500TPD oil fractionation project

--Protein and phospholipid project

--Grain processing project

Typical project

--10~1000TPD rice bran pretreatment & expansion and rice bran oil extraction project

--10~600TPD grade 1 rice bran oil refining project

--150~1000TPD cottonseed protein dephenolization project

--10~100TPH palm oil project

--10~2000TPD corn processing project

--10~500TPD non-acid catalysis biodiesel project

Latest Technology

--Oil deodorization and vacuum energy-saving technology

--Protein concentrate extraction technology

--Miscella refining technology

--Molecular distillation technology

--Extracting sugar from broken rice technology

--Fully-continuous lignite wax extraction technology (the first production line in Asia)

Engineering design scope&After-selling service scope

1). Craft flow chart

2). Equipment layout drawing;

3). Equipment base drawing;

4). Reserved hole & embedded parts drawing and civil engineering condition drawing;

5). Embedded pipeline layout drawing;

6). Embedded pipeline of power circuit drawing

7). Power electricity layout drawing;

8). Electricity distribution cabinet and operation table schema;

9). Plant layout drawing

10). Equipment installation & commission guidance and training work: