Cold Press Tea Seed Oil Camellia Oil Processing Equipment

Shenzhen Xiangfeizhu Technology Co., Ltd.- Type:Hydraulic Pressure Mechanism for Oil Press

- Application:All

- Voltage:380V

- Appearance:Vertical

- Press Materials:Tea Seed

- Press Series:Second

Base Info

- Condition:New

- Customized:Customized

- Transport Package:Bulk

- Specification:5TPD-500TPD

- Trademark:NO

- Origin:China

- HS Code:84792000

- Production Capacity:20set,Year

Description

Basic Info.

Condition New Customized Customized Transport Package Bulk Specification 5TPD-500TPD Trademark NO Origin China HS Code 84792000 Production Capacity 20set/YearProduct Description

Tea Seed/Camellia Oil Extraction Line

Tea seed oil (also known as tea oil camellia or oil-seed camellia) is an edible, pale amber-green fixed (nonvolatile) oil with a sweet, herbal aroma. It is cold-pressed mainly from the seeds of Camellia oleifera.

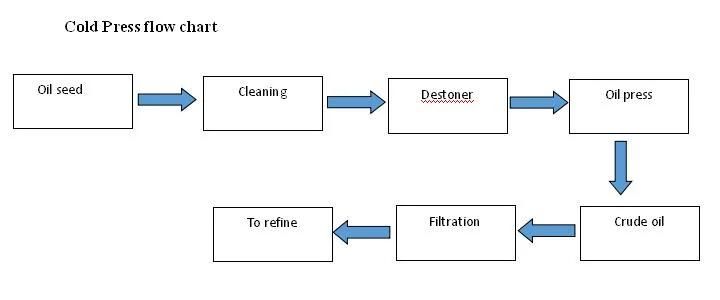

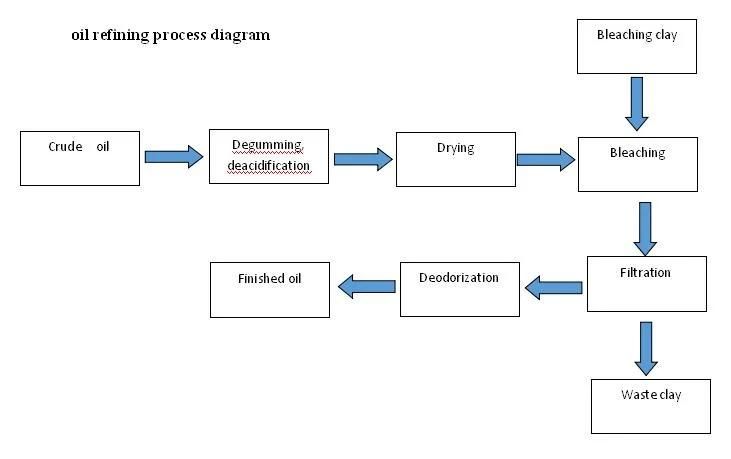

Tea seed Oil Processing Flow Diagram

Tea Seed Oil Production Workshop Pictures

Finished Tea Seed oil quality index

| Item | Quality index |

| Refined oil color(Lovibond cuvettes133.4mm) | Y30,R 3.0 |

| Smell,taste | No smell,good taste |

| Transparency | Clear and transparent |

| Moisture and volatile matter(%) | ≤0.05 |

| Insoluble impurities (%) | ≤0.05 |

| Acid value (mg KOH/g) | ≤0.2 |

| peroxide value m mol/kg) | ≤5.0 |

| Smoke Point/ºC | ≥215 |

| Residual solvent (mg/kg) | No |

Our company was estabished in 1950s ,now is one of the big oil equipment supplier in China .We have our own R&D department and installation service team with rich experience .

We have successfully obtained 27 national patents (7 invention patents), 6 international medals, 2 state awards, 2 provincial prizes Our machines sell well in more than 30 provinces, and exported to Egypt, Sudan, Tanzania, Rwanda,Nigeria,Estonia,Russia,Kazakhstan,Uzbekistan,Tajikistan,Bangladesh,Thailand,Malaysia,Indonesia, Bolivia,Peru and so on.Now we have developed into a major oil machinery manufacture base in China.

Our main project scope include

--10~5000TPD oilseed pretreatment project

--20~5000TPD solvent extraction project

--10~500TPD oil refining project

--10~500TPD oil fractionation project

--Protein and phospholipid project

--Grain processing project

Typical project

--10~1000TPD rice bran pretreatment & expansion and rice bran oil extraction project

--10~600TPD grade 1 rice bran oil refining project

--150~1000TPD cottonseed protein dephenolization project

--10~100TPH palm oil project

--10~2000TPD corn processing project

--10~500TPD non-acid catalysis biodiesel project

Latest Technology

--Oil deodorization and vacuum energy-saving technology

--Protein concentrate extraction technology

--Miscella refining technology

--Molecular distillation technology

--Extracting sugar from broken rice technology

--Fully-continuous lignite wax extraction technology (the first production line in Asia)

Engineering design scope&After-selling service scope

1). Craft flow chart

2). Equipment layout drawing;

3). Equipment base drawing;

4). Reserved hole & embedded parts drawing and civil engineering condition drawing;

5). Embedded pipeline layout drawing;

6). Embedded pipeline of power circuit drawing

7). Power electricity layout drawing;

8). Electricity distribution cabinet and operation table schema;

9). Plant layout drawing

10). Equipment installation & commission guidance and training work: