UV Resistance PC Polycarbonate Sunshine Roof Panel Manufacturing Machinery

Xinzheng Lifa Abrasives & Abrasives Co. LtdBase Info

Description

Basic Info.

Model NO. LMSB-120/35+45/30 Computerized Computerized Certification CE, ISO9001:2008 Customized Customized Condition New Sheet Size 2100mm Width*4-10mm Thickness Application Packing or Roofing or Construction etc Extruder Model Sj120/35 T-Die Head Jc-Times Brand Main Electrical Parts ABB, Omron, Rkc, Siemens, Eurotherm etc Delivery Time 90days Guaranteed Time 12 Months Machine Dimension 39m*7m*4.2m After Sale Service Engineers Are Available to Customer′s Factory Transport Package Wooden Pallet/Cases with Streching Films Specification LMSB-120/35 Trademark leader machinery Origin Qingdao, China HS Code 84772090 Production Capacity 25 Sets/Per YearProduct Description

2100mm width pc sunshine roof panels/sheets extruding line machine1. sheet width: 2100mm, thickness 4-6-8-10mm

2. sheet application: roofing panels,

3. extruder model: SJ-120/35+45/30

4. max capacity: 300-350kg/h

5. installed power: 520kw

6. certifications: CE, ISO9001-2008

7. Transportation: 3 sets of 40GP containers

Part 1 Introduction:

This pc hollow sheet extrusion line realizes continuous production of PC hollow grid sheet, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. It is characterized by light weight, high intensity,high transparency dampproof, and anticorrosion.

The technology of hollow sheet die with co-extrusion feed block to get UV+PC+UV, UV+PC hollow sheet can save 30% UV on the surface.

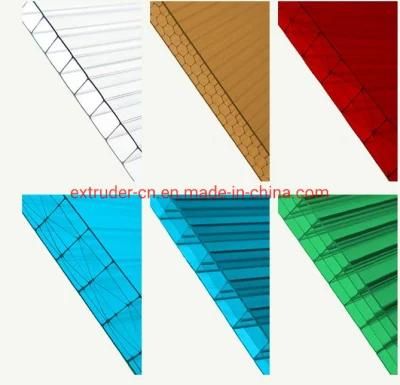

Part 2: Sheet Spcifications:

Sheet width: 700mm-1050mm- 1220mm-2100mm-2300mm,

Sheet thickness is 4mm-6mm-8mm-10mm-12mm.

Sheet walls: double walls

PART 3: This line consists of :

| Item | Description | Data |

| 1 | SJ120/35 Single screw extruder with stainless steel hopper | 1 set |

| 2 | Screen exchanging unit for PC | 1 set |

| 3 | Melting gear pump for PC | 1 set |

| 4 | SJ45/30 Single screw extruder for UV layer | 1 set |

| 5 | Melting gear pump for uv | 1 set |

| 6 | T-type Die head (2100mm*4-6mm) | 1 set |

| 7 | Vacuum calibrating board | 1 set |

| 8 | cooling table | 1 set |

| 9 | The first haul off machine with 12 rollers | 1 set |

| 10 | edge cutting device | 1 set |

| 11 | 5000mm oven | 1 set |

| 12 | Corona treating unit | 1 set |

| 13 | up and down sides, double position film laminating device | 1 set |

| 14 | The second haul off machine | 1 set |

| 15 | Tranverse cutting machine (length-settled) | 1 set |

| 16 | material conveyor+6000mm discharge table | 1 set |

| 17 | eletrical cabinet | 1 set |

| other accessory machine parts | ||

| 18 | 500kg mixing and drying machine | 1 set |

| 19 | AC-25 water chiller | 1 set |

| 20 | 15kw air compressor | 1 set |

| 21 | sheet crusher | 1 set |

Part 4: Applications:

PC hollow sheet is widely used in construction sunroof in buildings/halls/shopping center/stadium/public places of entertainment and public facility; Ring shield of bus station/garages/pergolas/corridors; noise barriers for highways and urban elevated road

Part 5 Products introduction

polycarbonate is best known for its very high impact resistance, fine optical clarity and excellen fire performance.

hollow polycarboante is also often named as strutural polycarbonate, cellular polycarbonate, channel polycarbonate or multiwall

polycarbonate.

polycarbonate hollow sheets offer the higher level of glazing performance where transparency along with high impact strength is of

vital importance. They have excellent physical, mechnical, electric as well as hot property which explains their high reputation in buildings

and decoration industry. They are sold all over the world, making great contribution to customer's beautiful life.

Polycarbonate hollow sheets applications:

1) Sunshades for stadium and bus shelters

2) Lighting for corridors, passages and subway entries

3) Bank ATMs

4) Sound and heat insulation for construction such as: houses

5) Canopies for agriculture greenhouse, zoos

6) PC sheets mainly used for building and decorating materials, greenhouse material, telephone booth, insulation shield express ways & highways

7) Office building, hotels, villas, stadium, schools, bus stop, terminals, hospitals, subway entry and exit doors, etc.

UV protection

solar radiation has a harmful component by UV rays which initiate degradation of many polymetric material including polycarbonate.

This depends on geographic locations, seasons etc. Polycarbonate sheets feature a specifically co-extruded UV absorption and

protection layer, which provides long-lasting high stability against demanaging UV radiation, protects againts outdoor weathering and

retains its original color and light transmission.

Material:

PC pellets (germany Baier brand with model 3113 or 3117)

UV material (germany Baier brand with model 510 or 130)

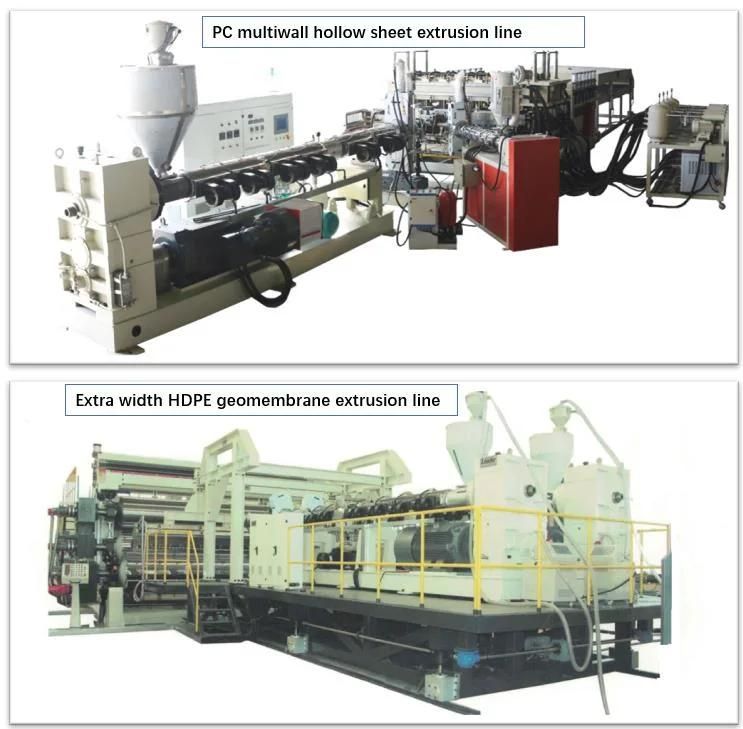

Part 6 Machine Images

Part 7 Company Information and main products

PART 8 COMPANY CERTIFICATIONS:

PART 9 OUR RELIABLE SUPPLIERS:

PART 9 OUR RELIABLE SUPPLIERS: PART 10 MACHINE PACKING AND DELIVERY:

PART 10 MACHINE PACKING AND DELIVERY: